Self-setting anti-corrosion protective agent applicable to marine atmosphere environment and preparation and application thereof

A marine atmosphere, self-curing technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of serious environmental pollution, can not provide protection, complex construction and other problems, achieve the effect of simple construction process, enhanced corrosion protection effect, easy to paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of self-curing anti-corrosion protective agent: by mass percentage, acrylic acid emulsion 65wt.%, nano cerium oxide 2wt.%, silane surface modifier 0.1wt.%, meteorological silica 12wt.%, mica iron oxide 17wt. %, alcohol ester twelve 2wt.%, pigment 1.9wt.%.

[0021] Preparation of conventional protective agent: by mass percentage, acrylic emulsion 65wt.%, meteorological silica 12wt.%, micaceous iron oxide 17wt.%, alcohol ester twelve 2wt.%, pigment 4wt.%.

[0022] The solid content of the above acrylic emulsion is 49%, the particle size of nano cerium oxide is 30nm; the silane surface modifier is purchased from Union Carbide Company, the particle size of meteorological silica is 100nm, and the pigment is water-based carbon black.

[0023] The saltwater resistance test of the self-curing anti-corrosion protective agent obtained by using the above-mentioned different protective agents in the marine atmospheric environment:

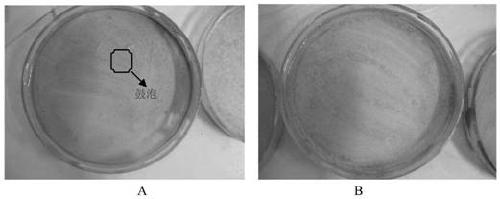

[0024] After the above two protectiv...

Embodiment 2

[0026] Preparation of self-curing anti-corrosion protective agent: by mass percentage, acrylic acid emulsion 63wt.%, nano cerium oxide 4wt.%, silane surface modifier 0.2wt.%, meteorological silica 12wt.%, mica iron oxide 17wt. %, alcohol ester twelve 2wt.%, pigment 1.8wt.%.

[0027] Preparation of conventional protective agent: by mass percentage, acrylic emulsion 60wt.%, meteorological silica 12wt.%, micaceous iron oxide 17wt.%, alcohol ester twelve 5wt.%, pigment 6wt.%.

[0028] The solid content of the above acrylic emulsion is 49%, the particle size of nano cerium oxide is 20nm; the silane surface modifier is purchased from Union Carbide Corporation, the particle size of meteorological silica is 100nm, and the pigment is water-based carbon black.

[0029] The saltwater resistance test of the self-curing anti-corrosion protective agent obtained by using the above-mentioned different protective agents in the marine atmospheric environment:

[0030] After the above two prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com