Reinforcing and antistatic light polyurethane foam and preparation method thereof

A polyurethane foam and antistatic technology, applied in the field of lightweight polyurethane rigid foam, can solve the problems of high cost, complex chemical modification process, too large dispersion and density difference, etc. The effect of high foam rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

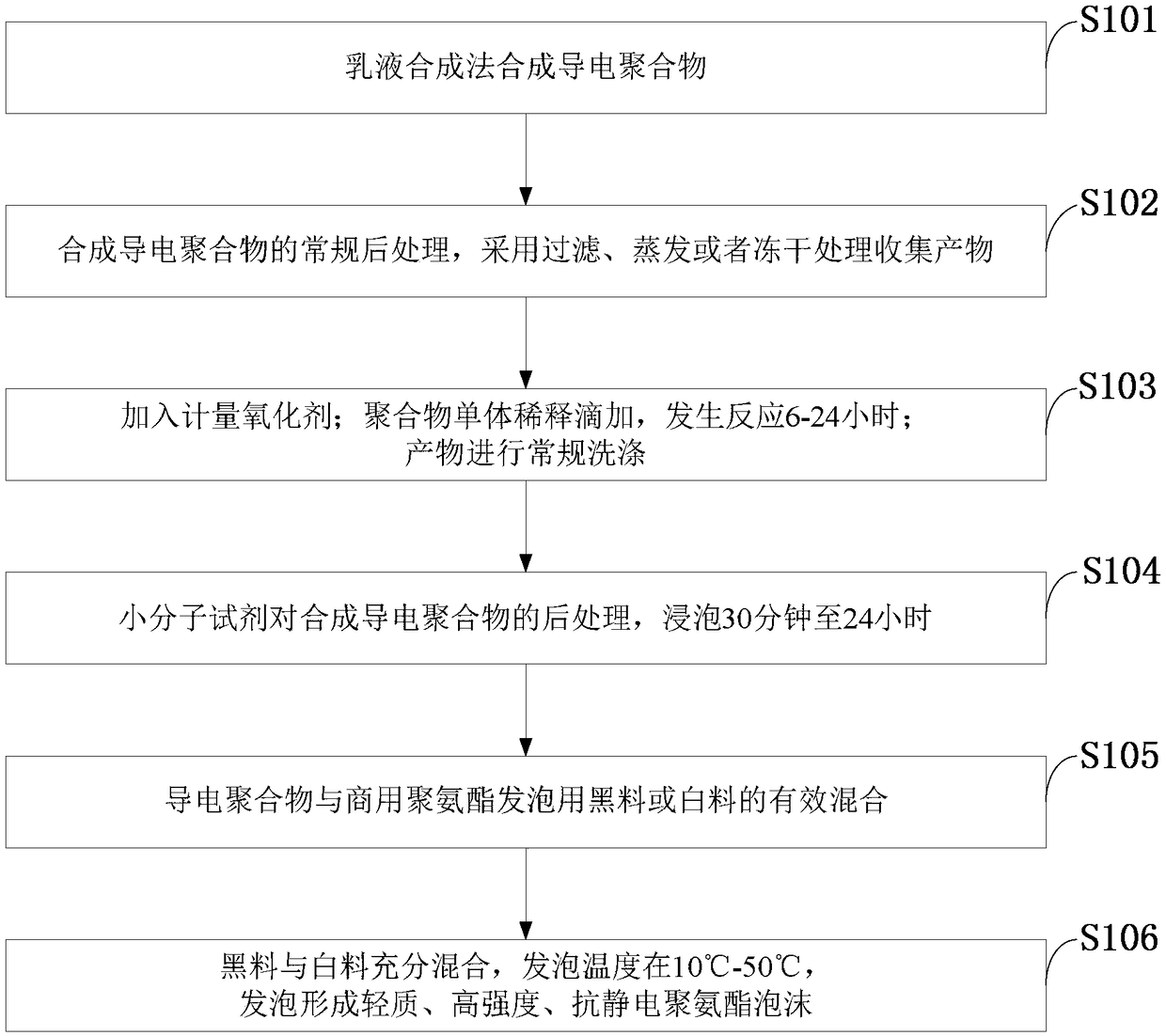

[0043] like figure 1 As shown, the preparation method of the lightweight polyurethane foam provided by the embodiments of the present invention has both reinforcement and antistatic properties, comprising the following steps:

[0044] S101: Emulsion synthesis method to synthesize conductive polymer;

[0045] S102: Conventional post-processing for synthesizing conductive polymers, collecting products by filtration, evaporation or freeze-drying;

[0046] S103: Add a metered oxidant; polymer monomer is diluted and added dropwise, and the reaction occurs for 6-24 hours; the product is routinely washed;

[0047] S104: post-treatment of small molecule reagents on the synthetic conductive polymer, soaking for 30 minutes to 24 hours;

[0048] S105: Effective mixing of conductive polymers with black or white materials for commercial polyurethane foams;

[0049] S106: The black material and the white material are fully mixed, and the foaming temperature is 10°C-50°C, and foamed to fo...

Embodiment 1

[0077] Embodiment 1: 1 gram of sodium dodecylbenzene sulfonate, 4..7 grams of ferric chloride are added to 100 milliliters of 50:50=H 2 O: CHCl 3 solution, after stirring for 0.5 h, a homogeneous solution was formed. 1 ml of pyrrole monomer was added to the solution to react for 24 hours to form a uniform black product. The product was washed with 150ml of methanol until the eluate was colorless and dried. Before foaming, soak the polypyrrole with the reinforcing agent for 24 hours and dry it, then blend the conductive compound with the black material, and foam it to obtain a conductivity of 10. 6-8 Ω·cm reinforced polyurethane foam with a density of 0.06g / cm 3 .

Embodiment 2

[0078] Embodiment 2: with 1 gram of sodium dodecylbenzene sulfonate, 4.66 gram of iron trichloride, 3ml 30%H 2 o 2 Add 100ml 30:70=H 2 O: CHCl 3 solution, after stirring for 0.5 h, a homogeneous solution was formed. 1 ml of pyrrole monomer was added to the solution to react for 24 hours to form a uniform black product. The product was washed with a mixture of methanol, water and methanol until the eluate was colorless. Before foaming, soak the polypyrrole with the reinforcing agent for 24 hours and dry it, then blend the conductive compound with the black material, foam, then blend the compound with the black material, and foam to obtain a conductivity of 10 6-8 Ω·cm polyurethane foam with a density of 0.05g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com