Micro-nano basic magnesium carbonate flame retardant and preparation method thereof

A magnesium carbonate, micro-nano technology, applied in the field of nanomaterials, can solve the problems of measurement of flame retardant effect without flame retardant, no green environmental protection characteristics, no green environmental protection and other problems, achieve good smoke suppression effect, reduce heat transfer effect, Excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of this flame retardant is as follows:

[0027] Prepare 200mL of aqueous sodium carbonate solution (0.1mol / L) and 200mL of magnesium chloride hexahydrate solution (0.1mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 50mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm ; After the addition is completed, put the mixed solution in an oven at 90°C for aging for 5 hours; after the aging is completed, filter out the precipitate, wash and dry at 30°C for 60 minutes; Fuel.

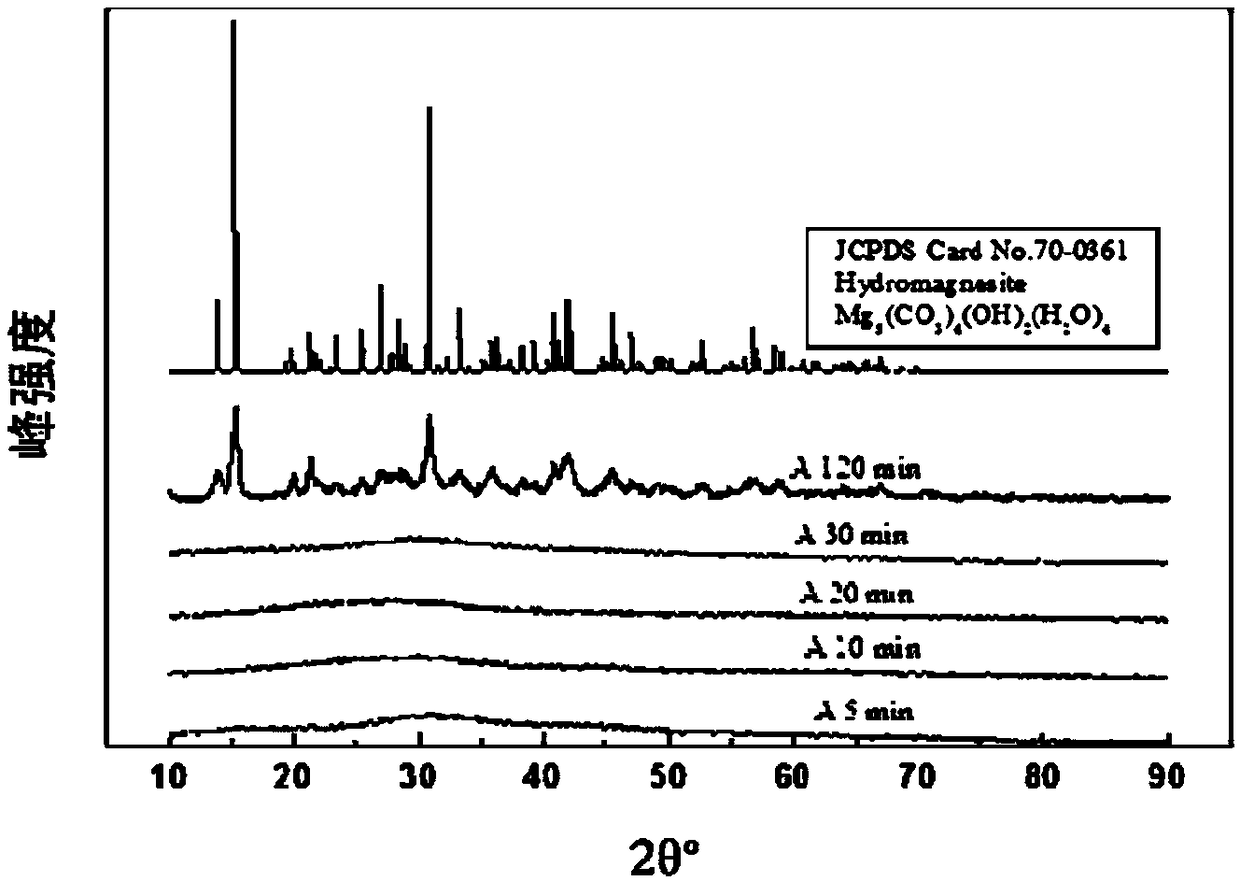

[0028] The nano basic magnesium carbonate flame retardant was imaged by scanning electron microscopy, and the results were as follows figure 1 As shown, the nanoparticles have a spherical structure, stacked by multi-layer nanosheets, similar to flower petals, and the particle size distribution is uniform, and the size of the nanoparticles is between 30 and 50 μm, and the shape stability is good. The X...

Embodiment 2

[0032] The preparation method of this flame retardant is as follows:

[0033] Prepare 200mL of aqueous sodium carbonate solution (0.1mol / L) and 200mL of magnesium chloride hexahydrate solution (0.1mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 1mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm After the addition is completed, the mixture is aged in an oven at 50°C for 5 hours; after the aging is completed, the precipitate is filtered out, washed and dried at 100°C for 60 minutes; after drying, the petal-shaped micro-nano basic magnesium carbonate barrier is obtained. Fuel.

[0034] The flame retardant effect test of this flame retardant is as follows:

[0035] Basic magnesium carbonate was spun into a film with a width of 15 mm and a thickness of 0.1 mm in the electrospinning solution doped with 5 wt % of cellulose acetate, and the combustion rate of the composite film was measured to be 498....

Embodiment 3

[0037] The preparation method of this flame retardant is as follows:

[0038]Prepare 200mL of aqueous sodium carbonate solution (1.5mol / L) and 200mL of magnesium chloride hexahydrate solution (1.5mol / L) respectively, and add the aqueous sodium carbonate solution dropwise at a rate of 1mL / min to the magnesium chloride hexahydrate solution stirred at a constant speed of 1000rpm ;After the addition is completed, put the mixed solution in a 50°C oven to mature for 0.5h; after the aging is completed, filter out the precipitate, wash and dry at 30°C for 60min; after drying, you can get petal-shaped micro-nano basic magnesium carbonate flame retardant.

[0039] The flame retardant effect test of this flame retardant is as follows:

[0040] Basic magnesium carbonate is spun into a film with a width of 15 mm and a thickness of 0.1 mm in the electrospinning solution doped with 5 wt % of cellulose acetate, and the horizontal and vertical combustion method measures the burning rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com