High-efficient wire material laser cladding method

A technology of laser cladding and wire materials, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low cladding efficiency and low utilization rate of laser energy, and achieve cladding efficiency improvement and line speed improvement and laser energy utilization, the effect of saving laser energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

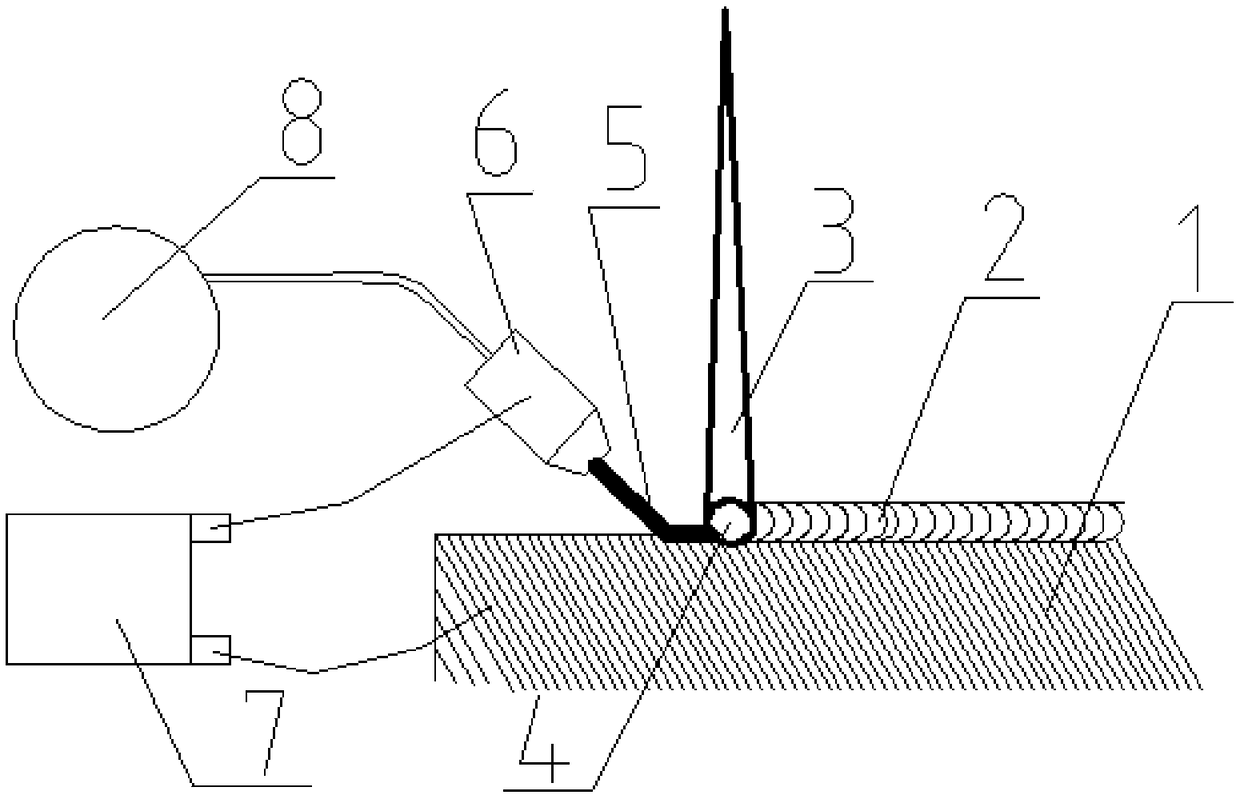

Image

Examples

Embodiment

[0050] Below in conjunction with embodiment, the present invention is described in further detail.

[0051] 1. This embodiment is laser cladding on the surface of the piston rod of the coal mine hydraulic support cylinder (later called the piston rod). The diameter of the piston rod is 70mm, the length of the cladding area is 1000mm, and the material is 27SiMn;

[0052] 2. The high-efficiency metal wire laser cladding scheme of the piston rod in this embodiment adopts a 4kW semiconductor fiber output laser from German Laserline Company, and the spot size formed by the laser beam on the surface of the piston rod is adjusted to be φ3mm, and the laser wavelength is 1064nm;

[0053] 3. The metal wire made of 316L solid stainless steel is selected, the cross-sectional shape of the wire is circular, and the diameter is φ1.2mm;

[0054] 4. The conductive tip is made of red copper, the wire passes through the center hole of the conductive tip, and the diameter of the center hole is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Section size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com