Hydrogenation desulfurization method of fluid catalytic cracking (FCC) gasoline

A hydrodesulfurization and gasoline technology, applied in chemical instruments and methods, processing hydrocarbon oil, petroleum industry, etc., can solve problems such as limitations, and achieve the effects of reduced production costs, mild reaction conditions, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

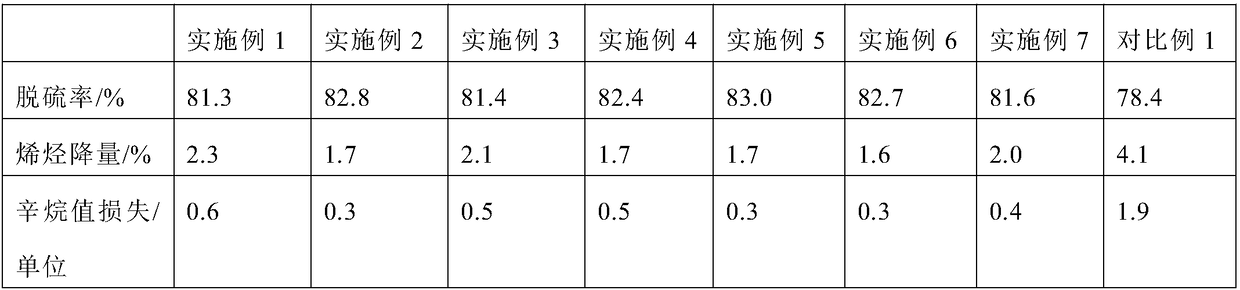

Embodiment 1

[0031] Use a beaker to measure 240 mL of deionized water, add 12.0 g of 68% nitric acid into the deionized water, mix evenly, and place in a water bath at 80°C. Weigh 6.0 g of sodium polyacrylate with a molecular weight of one million grades and add it into the prepared deionized water nitric acid solution, stir and completely dissolve to obtain an acid solution containing sodium polyacrylate.

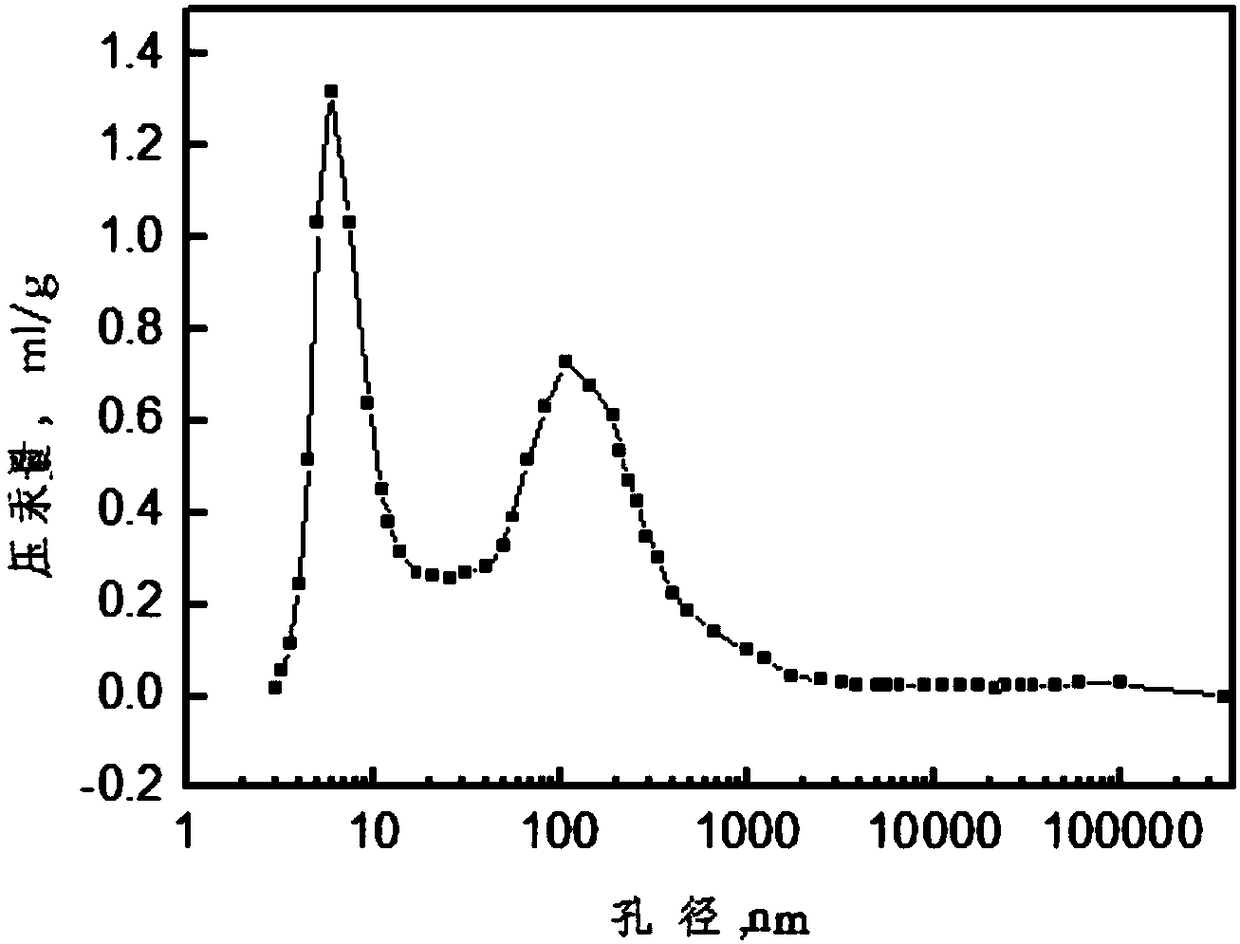

[0032] Weigh 300g of pseudo-boehmite powder and 15.0g of safflower powder, and mix them evenly. Add the acid solution of sodium polyacrylate to the pseudo-boehmite and squat powder, and knead-extrude them into a clover shape. Dry at 120°C for 8 hours, and calcined at 650°C for 4 hours to obtain macropore-containing alumina carrier A-1. The specific surface area and pore size distribution of the alumina support with macropores are shown in Table 1.

[0033] Get 233.3g of ammonium heptamolybdate, 17.32g of cobalt nitrate and join in 50ml of distilled water, add ammonia water to adjust t...

Embodiment 2

[0035] The preparation method of the acid solution of the pore-enlarging agent polyacrylic acid, kneading-extrusion, drying and roasting methods are carried out according to Example 1. The difference is that the million-grade sodium polyacrylate is replaced with ten-million-grade polyacrylic acid to obtain the alumina carrier A-2 with macropores. The specific surface area and pore size distribution of the alumina support with macropores are shown in Table 1.

[0036] Ammonium molybdate and cobalt nitrate were prepared as an impregnating solution, and ammonia water was added to adjust the pH value so that all the salts were dissolved, and then the alumina carrier A-2 containing macropores was impregnated. The specific steps were the same as in Example 1. Dry at 110°C for 6 hours, and calcined at 550°C for 8 hours to obtain catalyst 2. The main composition of the catalyst 2 is: 6wt% of cobalt oxide, 8wt% of molybdenum oxide, and 86wt% of carrier.

[0037] The hydrodesulfurizatio...

Embodiment 3

[0039] The preparation method of the acid solution of ammonium polyacrylate, kneading-extruding, drying and roasting methods are carried out according to Example 1. The difference is that the million-grade sodium polyacrylate is replaced by the one-hundred-thousand-grade ammonium polyacrylate to obtain the macropore-containing alumina carrier A-3. Its specific surface area and pore size distribution are shown in Table 1.

[0040] Ammonium molybdate and cobalt nitrate were prepared as an impregnating solution, and ammonia water was added to adjust the pH value so that all the salts were dissolved, and then the alumina carrier A-3 containing macropores was impregnated. The specific steps were the same as in Example 1. Dry at 130°C for 4 hours, and calcined at 580°C for 7 hours to obtain catalyst 3. The main composition of the catalyst 3 is: 2wt% cobalt oxide, 10wt% molybdenum oxide, and 88wt% carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com