Hydroxyapatite nanorod array structured coating co-doped with multiple elements on titanium-based surface and its preparation method and application

A technology of hydroxyapatite and nanorod arrays, which is applied in the direction of surface reaction electrolytic coating, coating, metal material coating technology, etc., can solve problems such as disorder, no configuration, and poor osseointegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

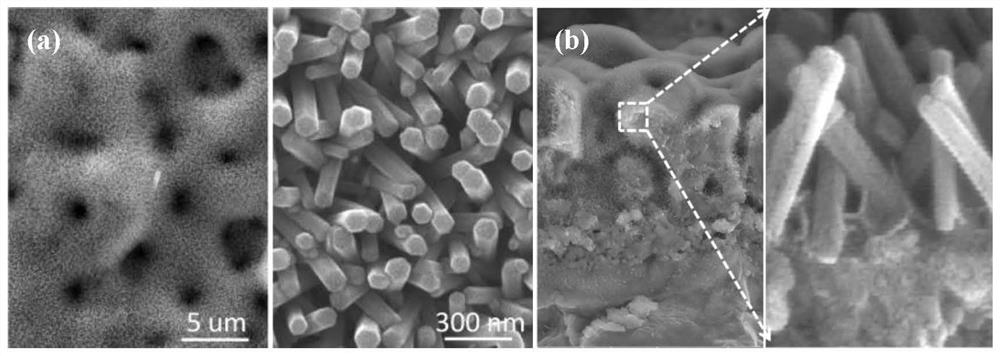

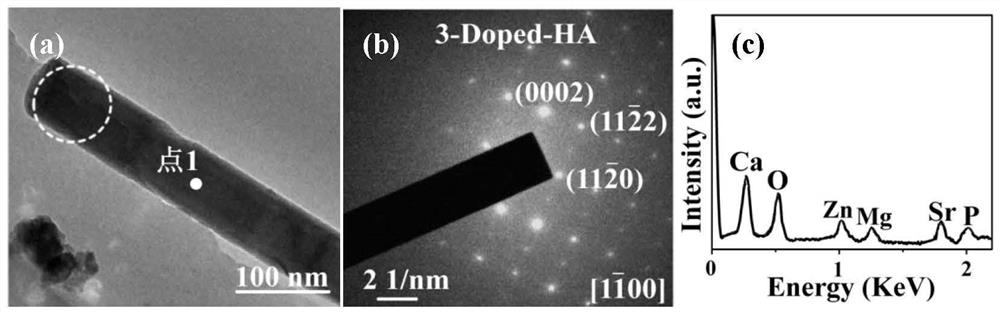

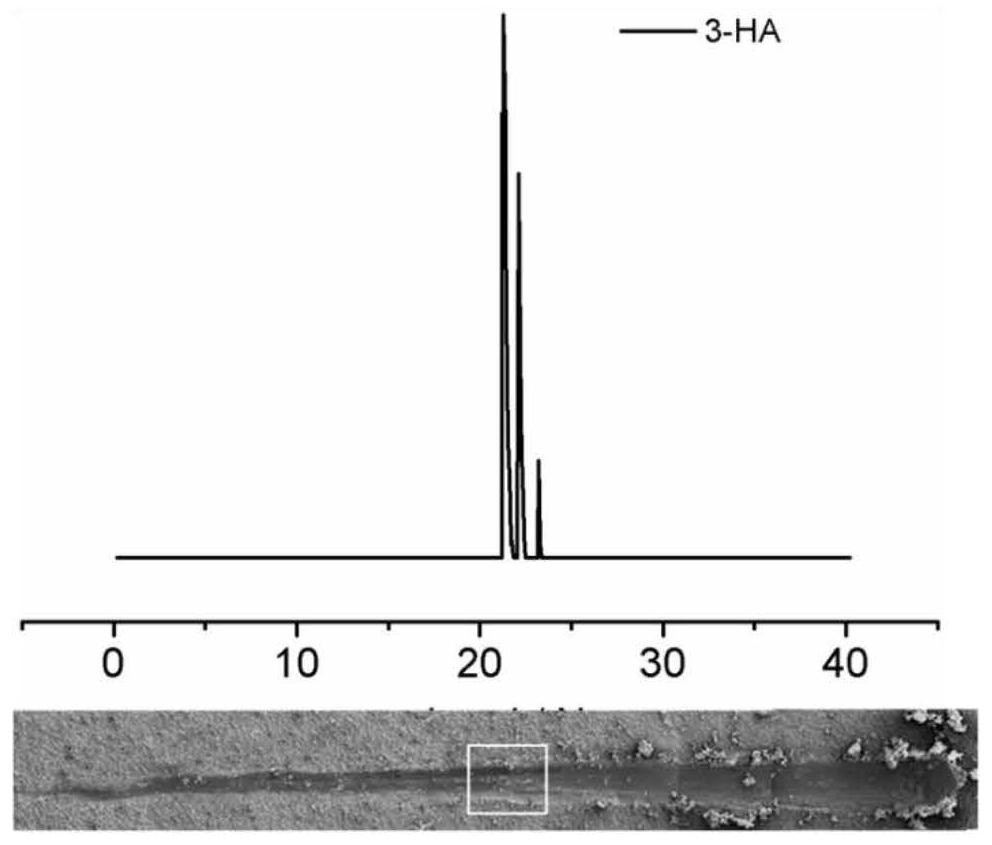

[0049] Will contain 0.11M (CH 3 COO) 2 Ca, 0.03M (CH 3 COO) 2 Sr, 0.03M (CH 3 COO) 2 Zn, 0.03M (CH 3 COO) 2 Mg and 0.02M β-C 3 h 7 Na 2 o 6 The aqueous solution of P(β-GP) is used as the electrolyte, and the metal titanium sheet is used as the anode, and the stainless steel is placed as the cathode in the electrolyte; a DC pulse power supply is used at a positive voltage of 400V, a negative voltage of 50V, a frequency of 100Hz, and a duty cycle of 7.5%. 1. Under the conditions of 8 cm distance between cathode and anode plates and electrolyte temperature of 25°C, the titanium sheet was subjected to micro-arc oxidation treatment for 5 minutes to obtain a titanium oxide-based composite layer containing calcium, strontium, magnesium and zinc. Then soak this titanium oxide-based composite layer / titanium sheet sample in a NaOH solution with a concentration of 0.03M in a hydrothermal reactor, and the filling degree of the solution is 15%. It is hydrothermally treated at 140...

Embodiment 2

[0051] Will contain 0.11M (CH 3 COO) 2 Ca, 0.03M (CH 3 COO) 2 Sr, 0.03M (CH 3 COO) 2 Zn, 0.03M (CH 3 COO) 2 Mg and 0.02M β-C 3 h 7 Na 2 o 6 The aqueous solution of P(β-GP) is used as the electrolyte, and the metal titanium sheet is used as the anode, and the stainless steel is placed as the cathode in the electrolyte; a DC pulse power supply is used at a positive voltage of 400V, a negative voltage of 50V, a frequency of 100Hz, and a duty cycle of 7.5%. 1. Under the conditions of 8 cm distance between cathode and anode plates and electrolyte temperature of 25°C, the titanium sheet was subjected to micro-arc oxidation treatment for 5 minutes to obtain a titanium oxide-based composite layer containing calcium, strontium, magnesium and zinc. Then soak this titanium oxide-based composite layer / titanium sheet sample in a NaOH solution with a concentration of 0.03M in a hydrothermal reactor, and the filling degree of the solution is 15%. It is hydrothermally treated at 140...

Embodiment 3

[0053] 0.155M (CH 3 COO) 2 Ca, 0.015M (CH 3 COO) 2 Sr, 0.015M (CH 3 COO) 2 Zn, 0.015M (CH 3 COO) 2 Mg and 0.02M β-C 3 h 7 Na 2 o 6 The aqueous solution of P(β-GP) is used as the electrolyte, and the metal titanium sheet is used as the anode, and the stainless steel is placed as the cathode in the electrolyte; a DC pulse power supply is used at a positive voltage of 400V, a negative voltage of 50V, a frequency of 100Hz, and a duty cycle of 7.5%. 1. Under the conditions of 8 cm distance between cathode and anode plates and electrolyte temperature of 25° C., micro-arc oxidation treatment was carried out on the titanium sheet for 5 minutes to obtain a titanium oxide-based composite layer containing strontium, magnesium and zinc. Then soak this titanium oxide-based composite layer / titanium sheet sample in a NaOH solution with a concentration of 0.03M in a hydrothermal reactor, and the filling degree of the solution is 15%. It is hydrothermally treated at 140°C for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com