Composite reduced chromium vanadium catalyst and preparation method thereof

A chromium-vanadium catalyst and catalyst technology, applied in the production of bulk chemicals, etc., can solve the problems of low active center activity, complex process, and unsatisfactory effects, and achieve high ethylene homopolymerization and copolymerization reactivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

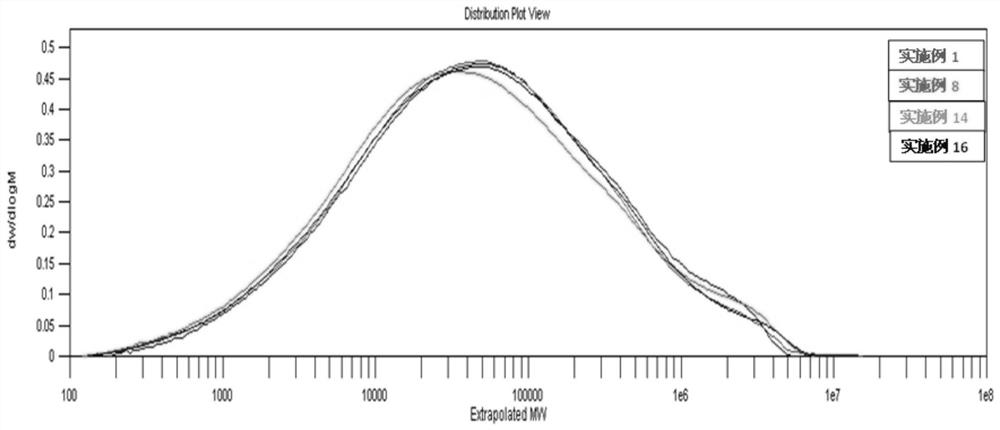

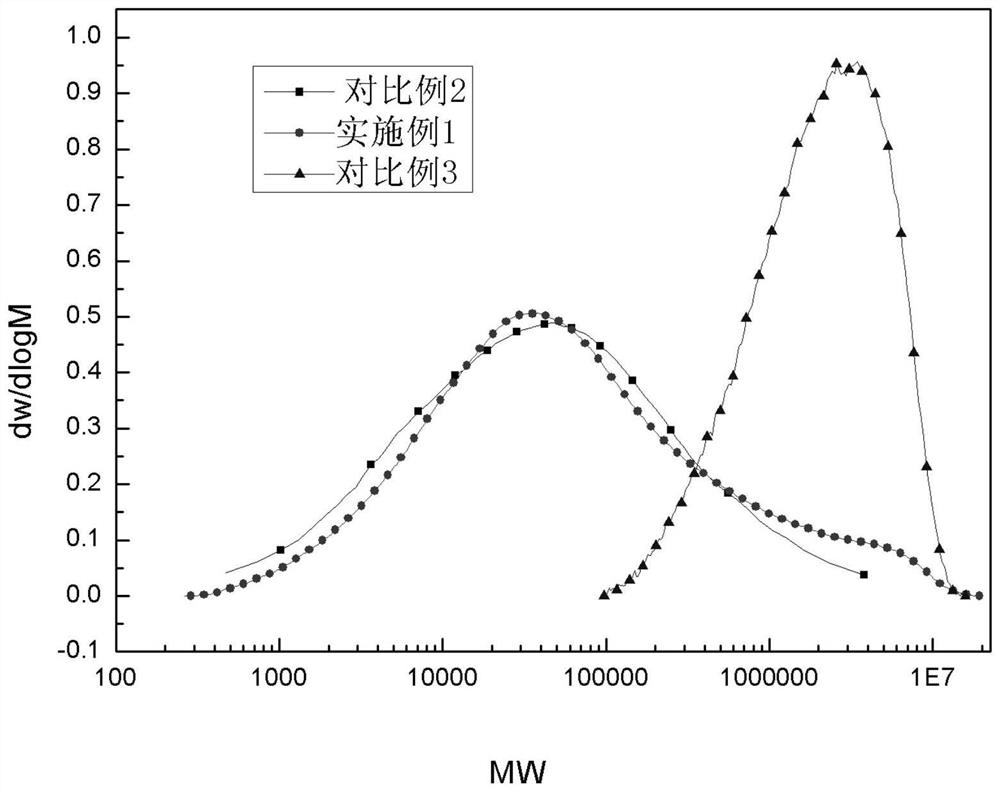

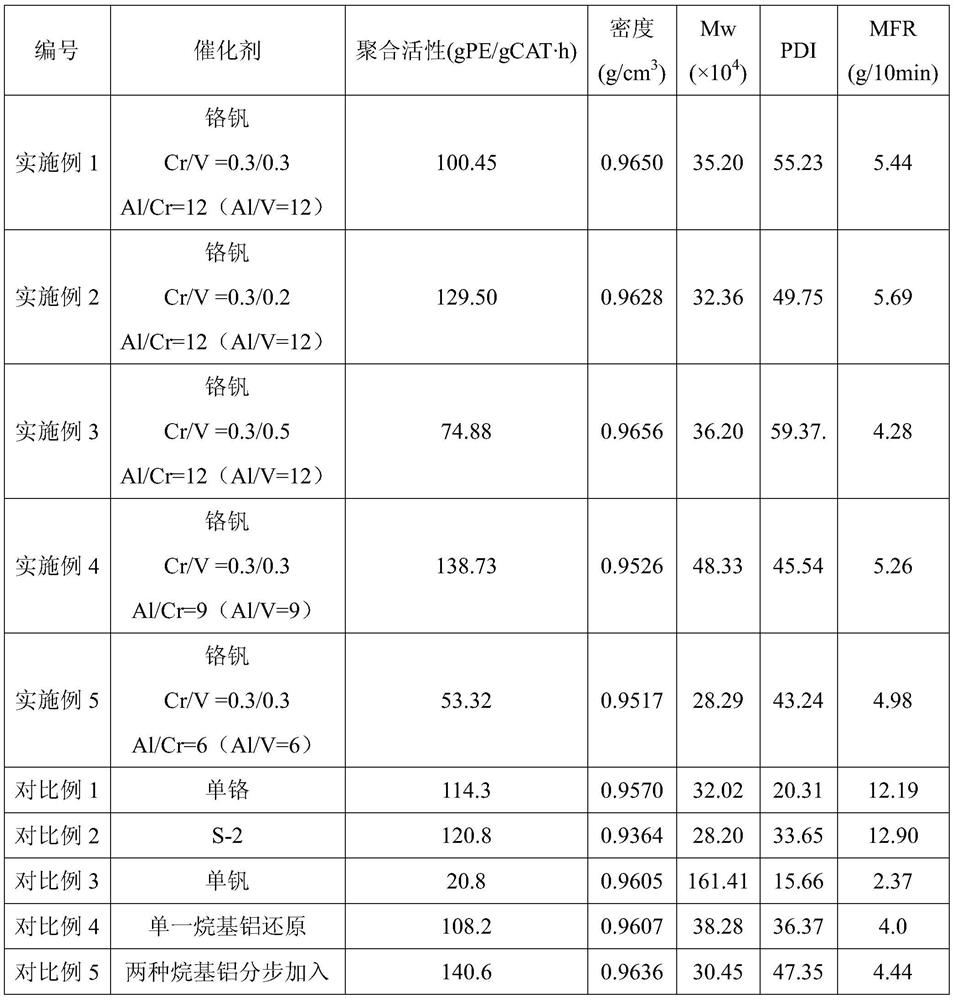

Embodiment 1

[0059] Select commercially available Davison 955 silica gel as the inorganic carrier; weigh 1.043g of chromium acetate, 0.2790g of ammonium metavanadate (the loading of chromium is 0.30wt%) (the loading of vanadium is 0.30wt%) and add them to 200ml of distilled water at 60°C , using continuous stirring, the stirring speed is 240 rpm to dissolve, and the dissolution time is 30min; then 40g of silica gel is soaked in the solution, and soaked at 60°C for 3h to make the active components evenly adsorbed in the micropores of silica gel; the above-mentioned whole process belongs to physical adsorption process. After drying at 120°C for 20 hours, transfer it to a fluidized bed for roasting, raise it to 200°C in a high-purity nitrogen atmosphere and keep it for 1 hour to remove physical water, then pass through dry air at 600°C for 4 hours, and then cool down naturally under nitrogen for later use .

[0060] Mix diethylaluminum ethoxide and triethylaluminum in a n-hexane solution at ...

Embodiment 2

[0064] Select commercially available Davison 955 silica gel as the inorganic carrier; weigh 1.043g chromium acetate (the chromium loading is 0.30wt%), weigh 0.1836g ammonium metavanadate (the vanadium loading is 0.20wt%) and dissolve in 200ml, 60°C Dissolve in distilled water with continuous stirring at a stirring speed of 240 rpm for 30 minutes; then soak 40 g of silica gel in the solution for 3 hours at 60 ° C to make the active components evenly adsorbed in the micropores of the silica gel; the above-mentioned whole The process belongs to the physical adsorption process. After drying at 120°C for 20 hours, transfer it to a fluidized bed for roasting, raise it to 200°C in a high-purity nitrogen atmosphere and keep it for 1 hour to remove physical water, then pass through dry air at 600°C for 4 hours, and then cool down naturally under nitrogen for later use .

[0065] Mix diethylaluminum ethoxy and triethylaluminum in a n-hexane solution at a molar ratio of 3:2 to prepare a...

Embodiment 3

[0069] Select commercially available Davison 955 silica gel as the inorganic carrier; weigh 1.043g chromium acetate, 0.3060g ammonium metavanadate (0.30wt% chromium loading, 0.50wt% vanadium loading), weigh and dissolve in 200ml, 60°C Dissolve in distilled water with continuous stirring at a stirring speed of 240 rpm for 30 minutes; then soak 40 g of silica gel in the solution for 3 hours at 60°C so that the active components are evenly adsorbed in the micropores of the silica gel; the above-mentioned whole The process belongs to the physical adsorption process. After drying at 120°C for 20 hours, transfer it to a fluidized bed for roasting, raise it to 200°C in a high-purity nitrogen atmosphere and keep it for 1 hour to remove physical water, then pass through dry air at 600°C for 4 hours, and then cool down naturally under nitrogen for later use .

[0070] Mix diethylaluminum ethoxy and triethylaluminum in a n-hexane solution at a molar ratio of 3:5 to prepare a mixed reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com