A Low-Cost Solar Cell Backside Polishing Process

A solar cell and backside polishing technology, which is applied in the direction of circuits, electrical components, photovoltaic power generation, etc., can solve problems such as the bad influence of back reflection of incident light on the battery, and achieve significant passivation effect, good optical gain, and smooth backside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

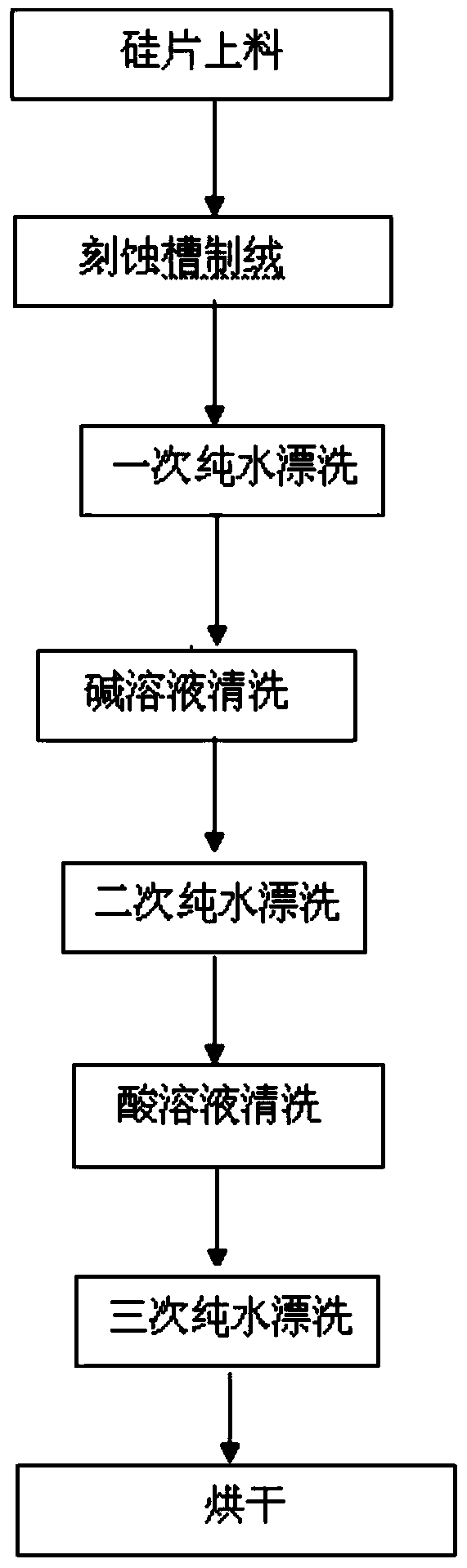

[0034] A kind of low-cost solar cell back polishing process that this embodiment provides, flow process is as follows figure 1 As shown, it includes the following process: silicon wafer feeding - cleaning silicon wafer surface oil stain - silicon wafer surface texturing and polishing - pure water rinsing - alkali cleaning - second pure water rinsing - pickling - three pure water rinsing - drying ,in:

[0035] T1: Silicon wafer loading, polycrystalline diamond wire cut silicon wafer is selected, and the thickness of the silicon wafer is 180um;

[0036] T2: Etching groove to make texture, place the silicon wafer in the etching groove to control the reaction speed of the upper and lower surfaces of the silicon wafer, so that the reflectance of the textured side of the silicon wafer is 21%-23%, and the non-textured surface on the back of the silicon wafer is polished, the reflectivity Control at 40%-55%;

[0037] The making of the texturing tank solution is specifically: the tex...

Embodiment 2

[0050] A kind of low-cost solar cell back polishing process that this embodiment provides, flow process is as follows figure 1 As shown, it includes the following process: silicon wafer feeding - cleaning silicon wafer surface oil stain - silicon wafer surface texturing and polishing - pure water rinsing - alkali cleaning - second pure water rinsing - pickling - three pure water rinsing - drying ,in:

[0051] T1: Silicon wafer loading, polycrystalline diamond wire cut silicon wafer is selected, and the thickness of the silicon wafer is 180um;

[0052] T2: Etching groove to make texture, place the silicon wafer in the etching groove to control the reaction speed of the upper and lower surfaces of the silicon wafer, so that the reflectivity of the textured side of the silicon wafer is 21%, and the non-textured surface of the silicon wafer is polished, and the reflectivity is controlled at 40%%;

[0053] The making of the texturing tank solution is specifically: the texturing t...

Embodiment 3

[0066] A kind of low-cost solar cell back polishing process that this embodiment provides, flow process is as follows figure 1 As shown, it includes the following process: silicon wafer feeding - cleaning silicon wafer surface oil stain - silicon wafer surface texturing and polishing - pure water rinsing - alkali cleaning - second pure water rinsing - pickling - three pure water rinsing - drying ,in:

[0067] T1: Silicon wafer loading, polycrystalline diamond wire cut silicon wafer is selected, and the thickness of the silicon wafer is 180um;

[0068] T2: Etching groove to make texture, place the silicon wafer in the etching groove to control the reaction speed of the upper and lower surfaces of the silicon wafer, so that the reflectance of the textured side of the silicon wafer is 23%, and the non-textured back of the silicon wafer is polished, and the reflectance is controlled at 55 %;

[0069] The making of the texturing tank solution is specifically: the texturing tank s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com