Impervious frost-resisting C30 concrete and preparation method thereof

A technology for concrete and antifreeze, which is applied in the field of building materials to prevent cracks, improve impermeability and improve impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

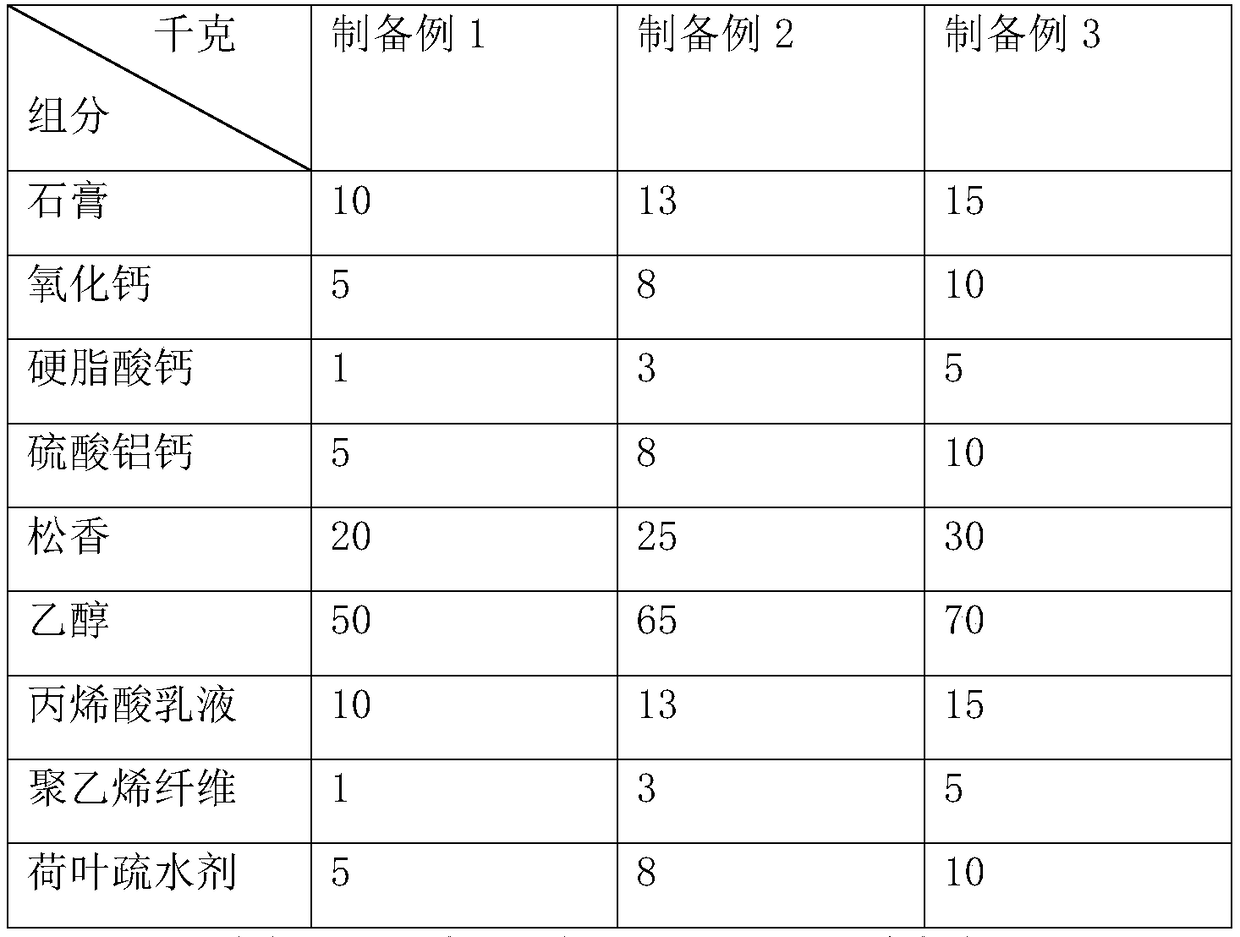

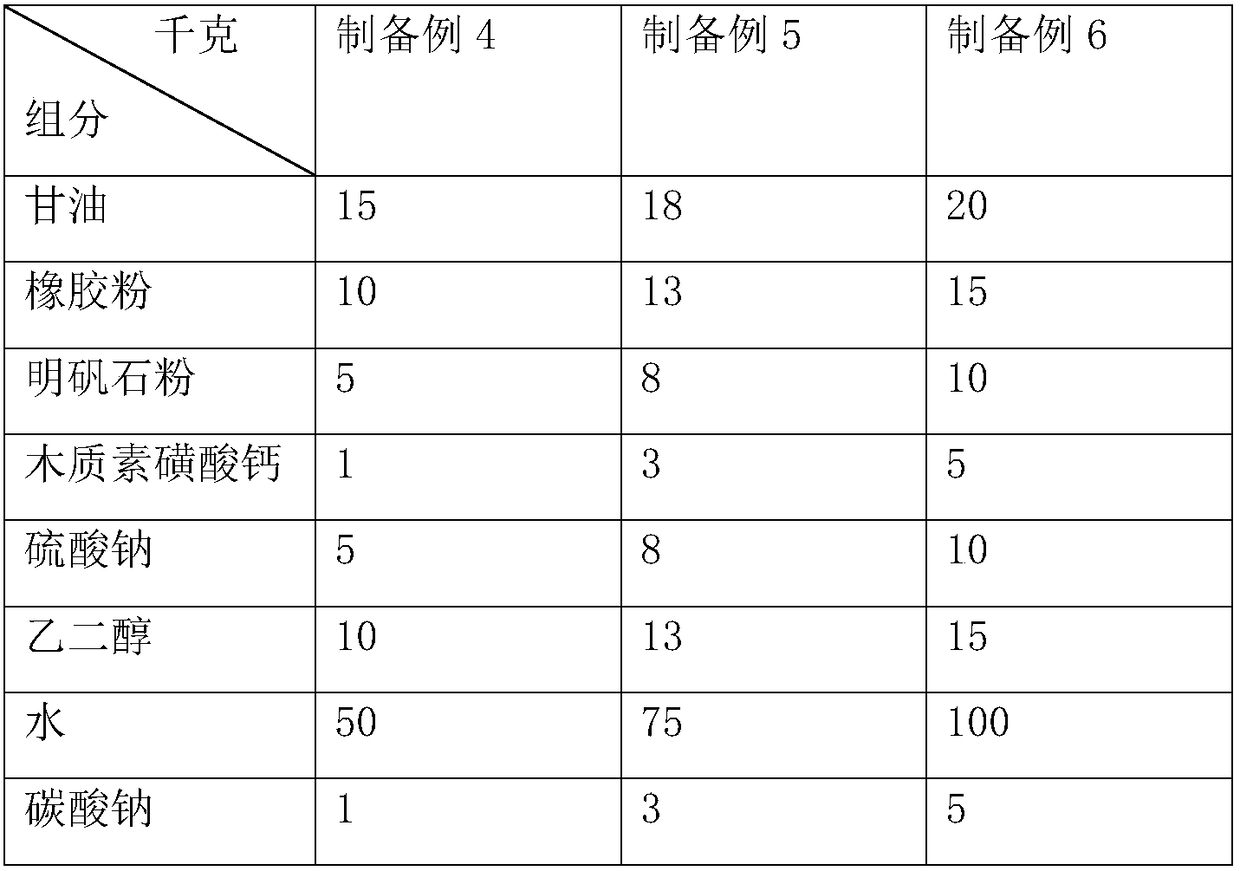

preparation example 1-3

[0040] In the preparation example 1-3, the acrylic emulsion is selected from the YC-8813 acrylic emulsion sold by Shandong Haoyao New Material Co., Ltd., and the lotus leaf hydrophobic agent is selected from the AD-SS lotus leaf hydrophobic agent sold by Guangzhou Angdi Chemical Co., Ltd., rosin The 145# rosin resin and gypsum sold by Hengshui Zehao Rubber Chemical Co., Ltd. are selected from the gypsum powder and polyethylene fiber sold by Xishan Dongbeitang Resonance Building Material Factory, and the product number is 95. The polyethylene fiber is selected from Nantong Kejia Textile Fiber Products Co., Ltd. UHMPE type polyethylene fiber.

preparation example 1

[0041] Preparation Example 1: (1) According to the ratio in Table 1, heat 5kg of calcium oxide and 10kg of gypsum to 1300°C, mix well, add 1kg of calcium stearate, 5kg of calcium sulfoaluminate and 1kg of polyethylene fiber for grinding , ground to a particle size of 0.1mm; (2) 50kg of ethanol was heated to 50°C, 20kg of rosin was added to the ethanol, stirred to dissolve the rosin, and the dissolved rosin, 10kg of acrylic acid emulsion and 5kg of lotus leaf hydrophobic agent were added to the The obtained product in step (1) is mixed evenly, dried, and ground into a powder of 0.05 mm.

[0042] The raw material ratio of expansion agent in table 1 preparation example 1-3

[0043]

preparation example 2

[0044] Preparation Example 2: (1) According to the proportioning in Table 1, heat 8kg of calcium oxide and 13kg of gypsum to 1400°C, mix well, add 3kg of calcium stearate, 8kg of calcium sulfoaluminate and 3kg of polyethylene fiber for grinding , ground to a particle size of 0.15 mm;

[0045] (2) 65kg ethanol is heated to 55 ℃, 25kg rosin is joined in the ethanol, stirs, and rosin is dissolved, and the rosin that dissolves, 13kg acrylic acid emulsion and 8kg lotus leaf hydrophobic agent are joined in step (1) gain, mix Dry it evenly and grind it into a powder of 0.06mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com