Quick starting method of efficient autotrophic nitrogen removal system based on MBBR

An autotrophic denitrification and quick-start technology, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problem of small ratio, low total nitrogen removal load, and sinking of fillers, etc. problems, to achieve the effects of small inoculation ratio, high nitrogen removal efficiency and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

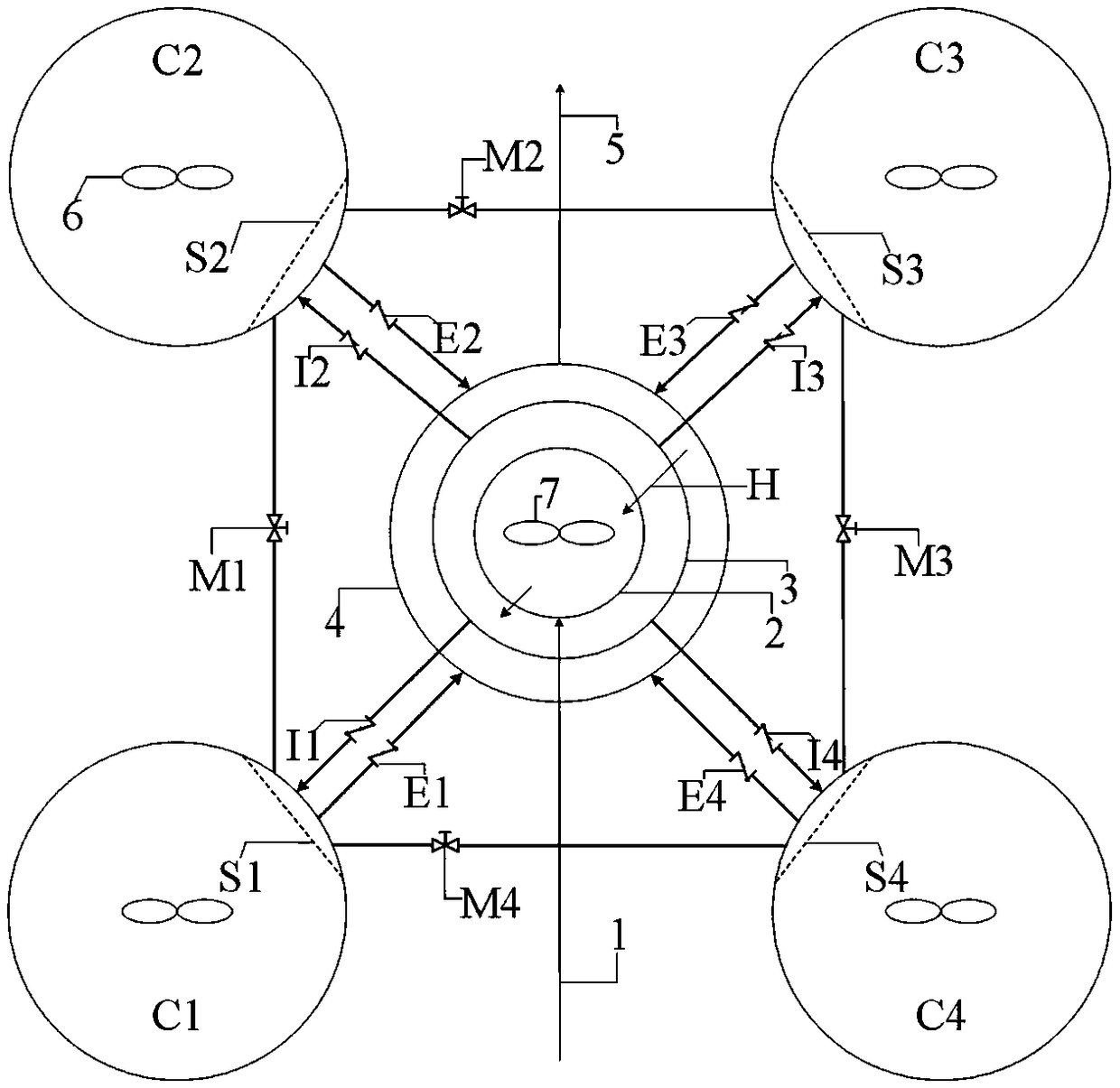

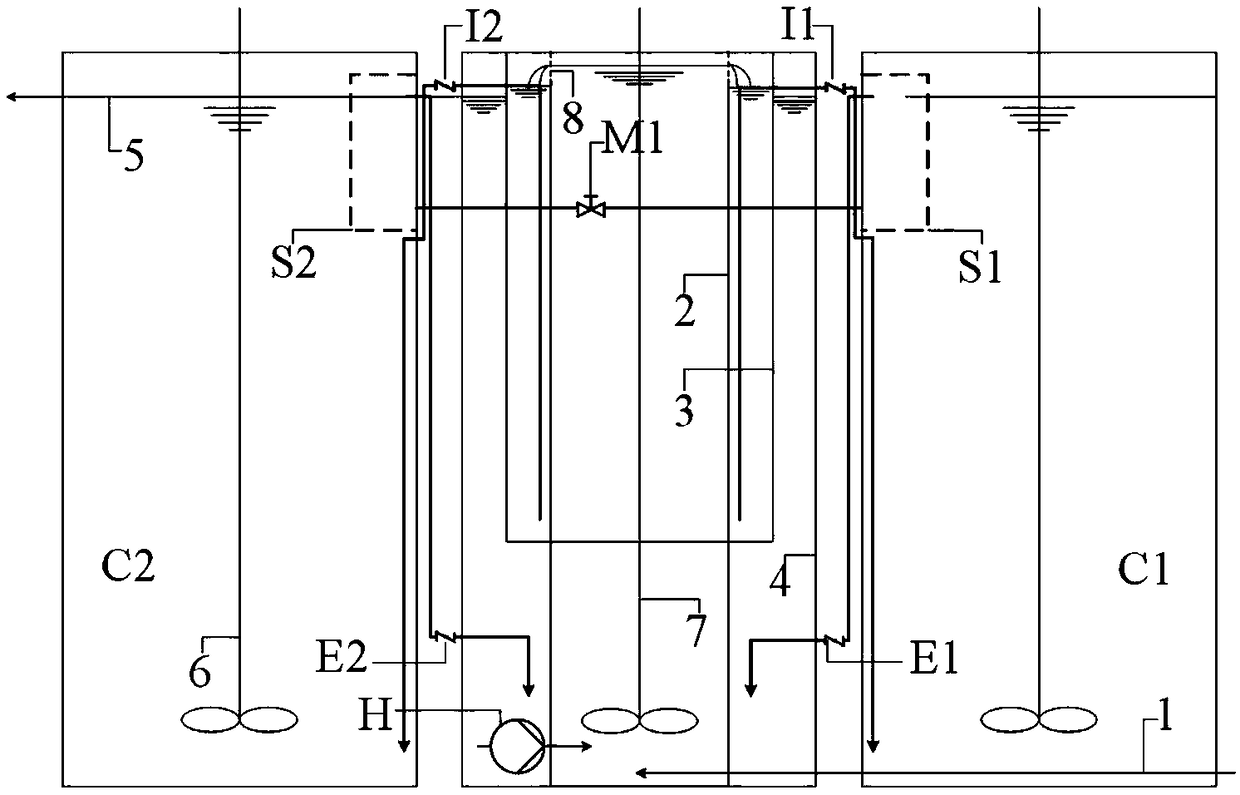

[0114] Take the anaerobic digested sludge dehydrated liquid of a municipal sewage treatment plant as the system inlet water, the water volume is 2500m 3 / d, average pH 7.9, average water temperature 32℃, average influent COD concentration 1131mg / L, BOD 5 The average concentration of 952mg / L, the average concentration of ammonia nitrogen 550mg / L, the average concentration of nitrous and nitrate nitrogen 2.0mg / L, the average alkalinity (in CaCO 3 Count) 3795mg / L, total effective volume of reaction tank 800m 3 , The effective volume of denitrification tank is 400m 3 , The inlet water enters the four reaction tanks C1-C4 through the denitrification tank.

[0115] Preparation for start-up. Suspended carrier is added to each reaction tank and denitrification tank. The effective specific surface area of the carrier is 800m. 2 / m 3 , The void ratio is 90%, in line with the industry standard of "High-density polyethylene suspended carrier for water treatment" (CJ / T461-2014), the filling ra...

Embodiment 2

[0124] Take the anaerobic digestion effluent of a landfill plant’s landfill leachate as feed water, with a water volume of 1300m 3 / d, pH 7.8-8.3, average water temperature 33℃, average influent COD concentration 920mg / L, BOD 5 The average concentration is 801mg / L, the average ammonia nitrogen concentration is 550mg / L, and the total effective volume of the reaction tank is 400m 3 , Divided into four reaction tanks, each with an effective volume of 100m 3 , The effective volume of denitrification tank is 200m 3 , The inlet water enters the four reaction tanks C1-C4 after passing through the denitrification tank.

[0125] Start-up preparation. Suspended carrier is added to the reaction tank and denitrification tank, and the effective specific surface area of the carrier is 800m 2 / m 3 , The void ratio is 90%, in line with the industry standard of "High-density polyethylene suspended carrier for water treatment" (CJ / T461-2014), the filling rate is 50%; the aerobic sludge is inoculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com