A kind of propeller processing technology

A processing technology and propeller technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve the problems of poor fluidity, high melting point of stainless steel, and difficult implementation of stainless steel, and achieve high implementability, overcome difficulties in manufacturing, and high toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of propeller processing technology, comprises the steps:

[0046] Step S1: cutting the stainless steel plate into blade-shaped blanks. The stainless steel plate in this embodiment is 420 stainless steel, and the stainless steel plate is the raw material for manufacturing propeller blades. The cutting can be completed by a laser cutting machine, and the blade blank after cutting is still a plate with uniform thickness.

[0047] Step S2: heating the blade blank to 1100-1300°C. This process is completed by sending the blade blank into the heating furnace, and the blade blank is in a red state after heating.

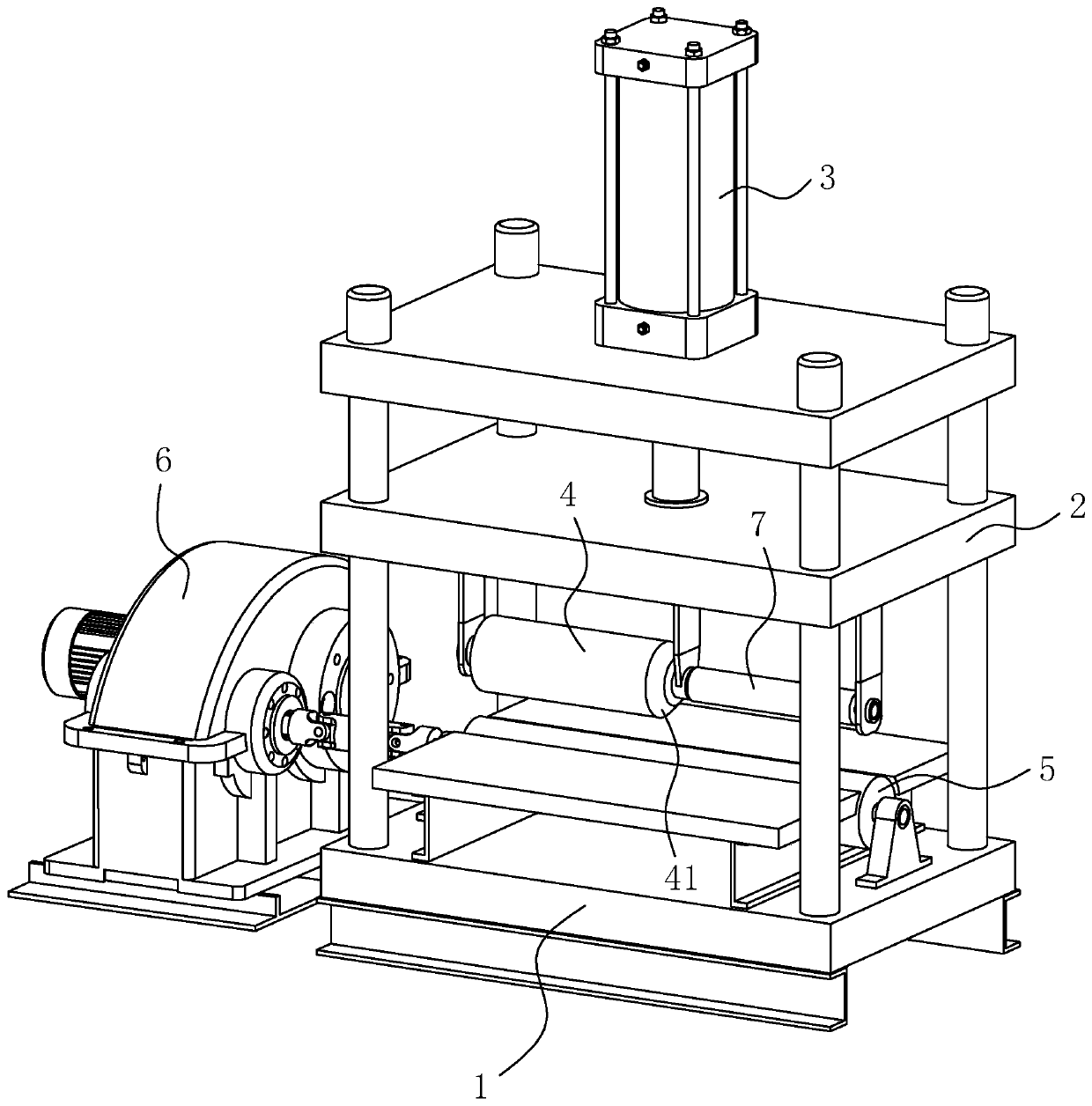

[0048] Step S3: Take the heated blade blank out of the heating furnace, and then press it into a required thickness by a hydraulic press. Step S3 includes Step S31 and Step S32.

[0049] Step S31: Using a hydraulic press to pressurize the board surface of the blade blank to form the required board thickness of the blade gradually changing.

[0050] Such as ...

Embodiment 2

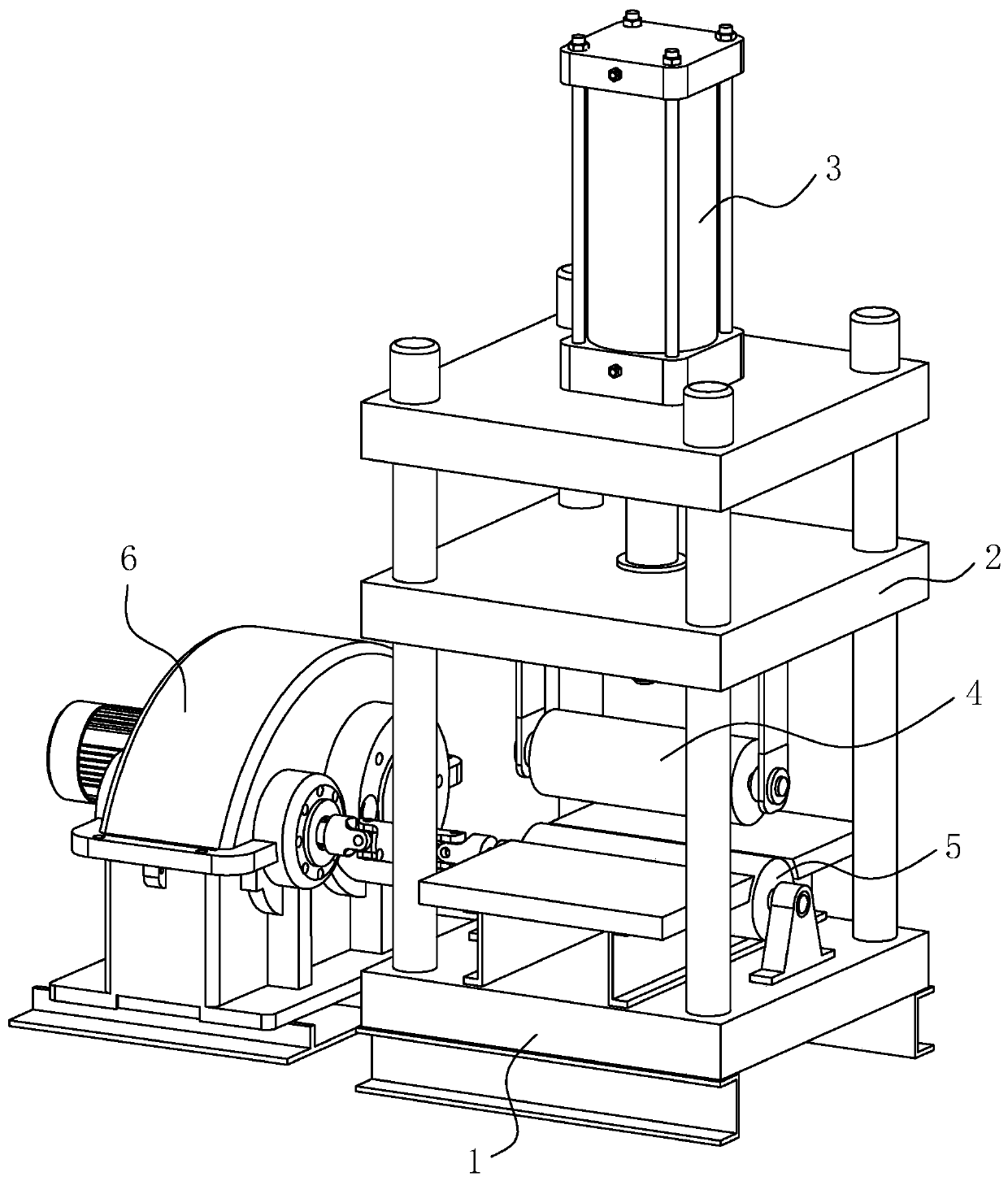

[0069] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the limit roller 7 is coaxially arranged at the end of the upper pressure roller 4 of the hydraulic press used in step S3, and the limit roller 7 is also rotated and arranged on the pressure plate 2. The axis of rotation of 7 coincides with the axis of rotation of the upper pressure roller 4, the diameter of the limit roller 7 is smaller than that of the upper pressure roller 4, and the upper pressure roller 4 is provided with an inclined secondary pressure surface 41 towards the axial end of the limit roller 7, The auxiliary pressing surface 41 is tapered, and the auxiliary pressing surface 41 is used to shape the edge thickness of the blade gradually;

[0070] When step S31 is executed, the blade is placed under the upper pressing roller 4 for processing. When step S32 is executed, the blade is placed under the limit roller 7 for processing. During processing, the edge of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com