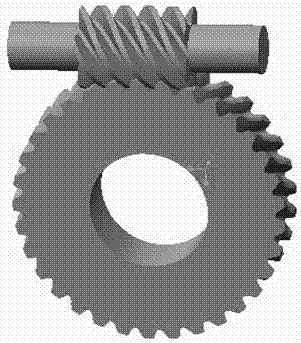

Arc-shaped face contact worm wheel and worm transmission power device

A worm gear, power device technology, applied in the direction of gear transmission, transmission, winch, etc., can solve the problems of reducing the bearing capacity and life of the worm pair transmission, increasing the transmission noise of the reducer, and affecting the transmission accuracy. Optimizing dynamic mesh performance, overcoming difficult manufacturing, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The utility model relates to an arc-shaped surface contact worm gear transmission power device for an escalator, and the worm is processed by a disc-shaped grinding wheel. figure 1 Schematic diagram of machining a worm for a disc wheel. First of all, according to the tooth surface equation of the disc grinding wheel and the actual processing parameters, combined with the design principle of the worm to determine the tooth surface equation of the worm, as shown in the figure, when processing the worm, when the worm is processed, the axis of the worm and the ring of the grinding wheel The axis of the surface (production surface) is installed with the helix angle of the worm indexing cylinder as the installation angle; the worm performs helical motion with certain helical characteristic parameters, and at the same time the grinding wheel rotates around its own axis to grind the worm tooth surface. Thus processing the worm. Then, according to the tooth surface equation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com