Propeller Manufacturing Process Based on Precision Casting

A technology of precision casting and manufacturing process, applied in the field of ships, can solve the problems of hardness, cutting performance difference, copper propellers are not interoperable, stainless steel has poor fluidity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0042] A kind of propeller manufacturing process based on investment casting, comprises the following steps:

[0043] Step S1: casting propeller blades by precision casting.

[0044] The investment casting method in this embodiment is an investment casting process. The investment casting process is to make a fusible model with fusible materials (such as wax or plastic), and coat several layers of special refractory coatings on it. After drying and hardening to form an integral s...

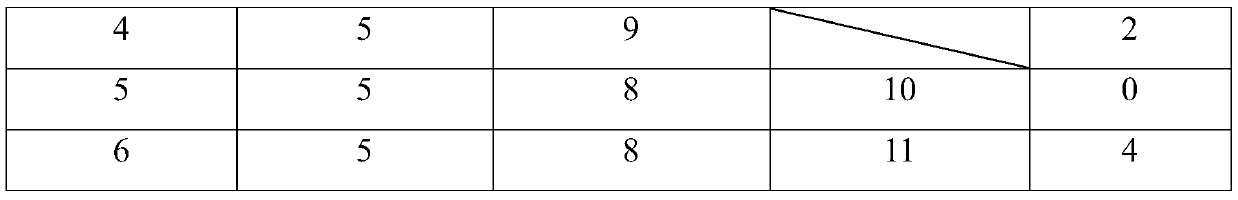

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com