One-way elastic woven fabric with warp or weft high elasticity and production method thereof

A technology of elastic fabrics and elastic machines, applied in the direction of fabrics, textiles, plant fibers, etc., can solve the problems of insufficient high temperature resistance or wear resistance, and achieve the effect of improving interface strength, increasing interface strength, and improving fiber body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

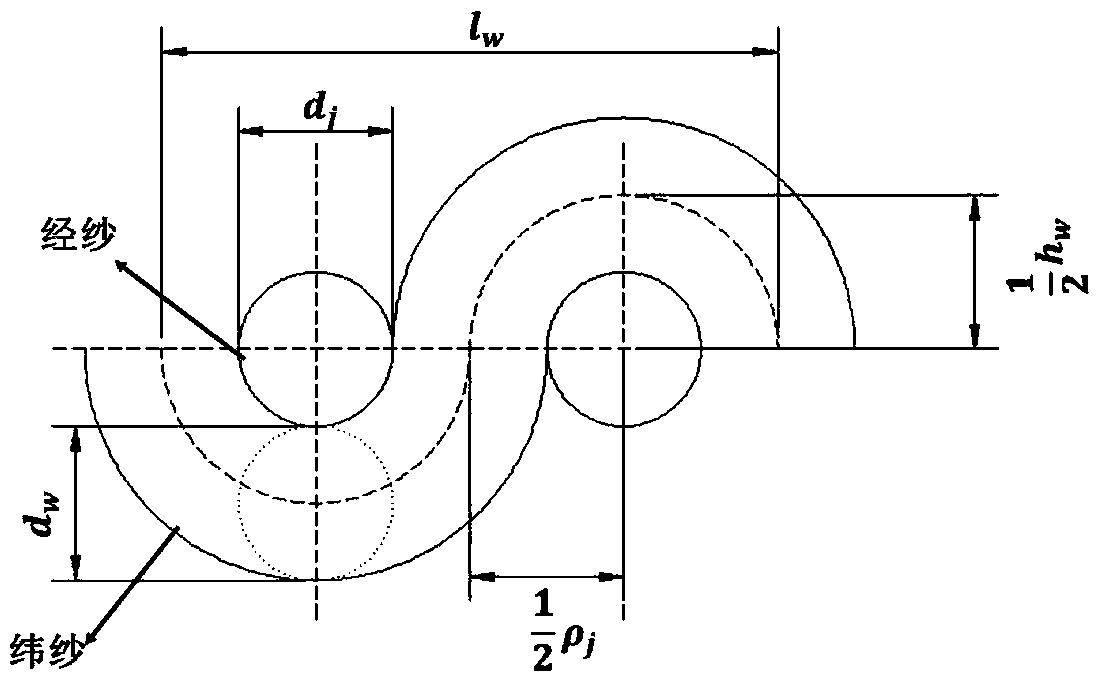

[0034] The present embodiment provides a kind of unidirectional elastic fabric with weft high elasticity, at first from the angle of fabric structure design low structure phase fabric (nearly 1 structure phase), warp and weft yarn raw materials all choose nylon 66 multifilament 65d / 450f, warp and weft yarn The filaments all adopt Z twist, the twist coefficient is 330, and the fabric weave is plain weave.

[0035] The weft high elastic woven fabric adopts a large warping tension during warping, and the machine tension of the warp yarn is large when weaving on the air-jet loom, which is 150% to 200% of the general machine tension, about 2.7kN to 3.0 kN, the warp yarn in the fabric is as straight as possible; weaving on the air-jet loom, the weft insertion tension is small, and the weft yarn is fully buckled in the fabric structure with the licker-in roller edge with small tension.

[0036] Immediately after the high elastic woven fabric is off the machine, low-cost CaCl 2 As a co...

Embodiment 2

[0044] This embodiment provides a kind of unidirectional elastic fabric with warp direction high elasticity, at first from the angle of fabric structure design high structure phase fabric (nearly 9 structure phases) back road fiber and yarn preparation before weaving and weft elastic fabric production The process is the same, but when weaving on the upper machine, set a weak tension on the upper machine so that the warp yarn tension meets the weaving requirements, and at the same time make the warp yarn woven into the fabric fully buckle; while the weft yarn adopts rapier weft insertion or multi-nozzle air jet weft insertion, using The full-width temple increases the tension of the temple so that the weft yarn woven into the fabric is fully straightened. After the fabric is off the machine, it is treated with a dipping process to cure the structure of the high-structure phase of the fabric and endow the fabric with lasting unidirectional warp elasticity.

[0045] Since radial ...

Embodiment 3

[0047] This embodiment provides a production method of a unidirectional elastic woven fabric with high elasticity in the warp or weft direction. The process includes "winding → warping → sizing → piercing and knotting → weaving → dipping".

[0048] The raw materials of warp and weft yarns of the novel structural elastic unidirectional elastic woven fabric can be natural fibers such as cotton, linen, silk, wool, etc. or general synthetic fibers such as viscose, polyester, nylon, acrylic, etc., or high-performance fibers such as carbon fiber, aromatic fiber, etc. Nylon, ultra-high molecular weight polyethylene, etc., the preferred raw material is nylon 66 filament; this embodiment takes nylon 66 filament as an example for introduction.

[0049] Said novel structure raw elastic unidirectional elastic fabric, warp and weft yarn fineness is 5-50 tex, warp and weft yarn twist is Z twist or S twist, and twist coefficient is 300-400.

[0050] When producing weft unidirectional elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com