A low-cost electrochemical deposition method for preparing rare earth metal terbium thin films

A rare earth metal and electrochemical technology, applied in optics, improvement of process efficiency, instruments, etc., can solve the possibility of increasing the production cost of ionic liquids, environmental pollution, no large-scale practical application background, and reduce the green characteristics of ionic liquids, etc. , achieve good chemical and thermal stability, excellent solubility, and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

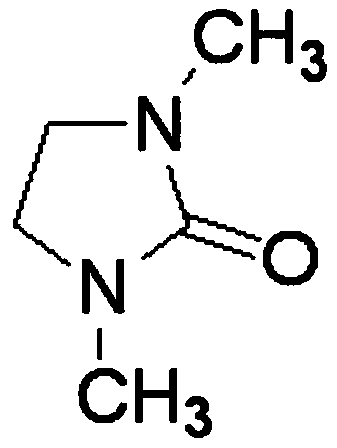

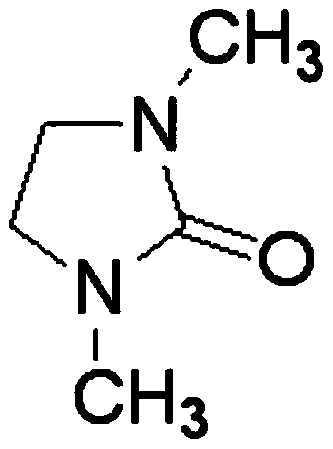

Embodiment 1

[0034] The raw materials for preparing the electrolyte are terbium chloride and lithium nitrate, and solvent DMI, which are stirred and mixed in the electrolytic cell to form an electrolyte system, wherein the molar concentrations of terbium chloride and lithium nitrate are 0.01mol / L and 0.01mol / L, respectively. Control the constant temperature of the electrolyte system at 25°C, the electrolysis voltage is -2.0V (vs Ag), and the cathode material is high-purity aluminum sheet; after 30 minutes of electrolysis, add terbium chloride once to make the concentration of terbium chloride in the system 0.01mol / L; electrolysis for 60 minutes Afterwards, the substrate is collected and preserved together with the sediment. After characterization and testing, the results show that metal terbium can be effectively deposited. The total content of terbium elements detected by ICP is 76.62%. The deposited film obtained by SEM observation is a uniform and dense deposited film, and the thickness ...

Embodiment 2

[0036]The raw materials for preparing the electrolyte are terbium chloride and lithium nitrate, and solvent DMI, which are stirred and mixed in the electrolytic cell to form an electrolyte system, wherein the molar concentrations of terbium chloride and lithium nitrate are 0.02mol / L and 0.02mol / L, respectively. Control the constant temperature of the electrolyte system at 35°C, the electrolysis voltage is -2.1V (vs Ag), and the cathode material is high-purity copper sheet; after 30 minutes of electrolysis, add terbium chloride once to make the concentration of terbium chloride in the system 0.02mol / L; electrolysis for 60 minutes Afterwards, the substrate is collected and preserved together with the sediment. After characterization and testing, the results show that metal terbium can be effectively deposited. The total content of terbium elements detected by ICP is 97.47%. The deposited film obtained by SEM observation is a uniform and dense deposited film, and the thickness of ...

Embodiment 3

[0038] The raw materials for preparing the electrolyte are terbium chloride and lithium nitrate, and solvent DMI, which are stirred and mixed in the electrolytic cell to form an electrolyte system, wherein the molar concentrations of terbium chloride and lithium nitrate are 0.03mol / L and 0.03mol / L, respectively. Control the constant temperature of the electrolyte system at 45°C, the electrolysis voltage is -2.2V (vs Ag), and the cathode material is high-purity aluminum sheet; after 30 minutes of electrolysis, add terbium chloride once to make the concentration of terbium chloride in the system 0.03mol / L; electrolysis for 60 minutes Afterwards, the substrate is collected and preserved together with the sediment. After characterization and testing, the results show that metal terbium can be effectively deposited. The total content of terbium elements detected by ICP is 97.74%. The deposited film obtained by SEM observation is a uniform and dense deposited film, and the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com