Adhesive resin for formaldehyde-free plywood and preparation method

A technology for bonding resins and plywood, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems affecting the initial bonding performance and bonding durability, poor wettability, large cohesive energy, etc., and achieve low cost , Improving wettability and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

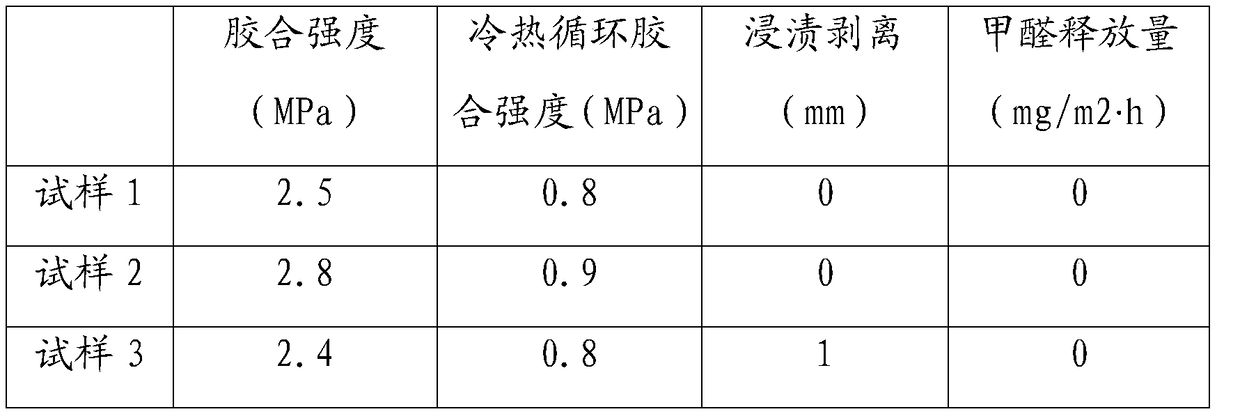

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned adhesive resin for formaldehyde-free plywood is to extrude and granulate each component of the above-mentioned raw material formula according to the above-mentioned proportions by using a twin-screw extruder to perform a plasticizing and blending process.

[0032] The above-mentioned low-density polyethylene is a copolymer of ethylene and a-olefin, with a density of 0.91-0.94g / cm 3 , The melt index is 2-18g / 10min.

[0033] The preparation of the above-mentioned functionalized modified polyethylene, its raw material formula is as follows (the following is the weight percentage content): 60%-90% high-density polyethylene, 10%-30% low-density polyethylene, 0.1%-5% Malay Acid anhydride or acrylic acid, 0.01%-0.5% of bis-2,5-hexane or dicumyl peroxide, fully mixed, and granulated through a reactive twin-screw extruder, the twin-screw extruder The temperature is controlled at 160°C-230°C, the screw speed is controlled at 250-450r...

Embodiment 1

[0040] A raw material formula (below is weight percent content) of adhesive resin for formaldehyde-free plywood is as follows:

[0041] 55% LDPE

[0042] 30% functionalized modified polyethylene

[0043] 5% Polyurethane

[0044] 10% polyolefin elastomer

[0045] 0.1% thermal oxygen stabilizer

[0046] Wherein the raw material formulation of functionalized modified polyethylene (below is weight percent content) is as follows:

[0047] 88.7% HDPE

[0048] 10.6% LDPE

[0049] 0.6% maleic anhydride monomer

[0050] 0.1% bis-2,5-hexane

Embodiment 2

[0052] 55% LDPE

[0053] 23% functionalized modified polyethylene

[0054] 10% Polyurethane

[0055] 12% Polyolefin Elastomer

[0056] 0.1% thermal oxygen stabilizer

[0057] Wherein the raw material formulation of functionalized modified polyethylene (below is weight percent content) is as follows:

[0058] 83.85% HDPE

[0059] 15% LDPE

[0060] 1.0% maleic anhydride monomer

[0061] 0.15% bis-2,5-hexane

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com