A modified hexagonal boron nitride powder and its preparation method and application

A hexagonal boron nitride, modified technology, used in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of low thermal conductivity, high processing cost, large wear, etc., and achieve excellent bending strength and performance. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Measure 200ml of ethanol, weigh 4g of hexagonal boron nitride (HBN), mix the two and stir with a glass rod, seal with plastic wrap and perform ultrasonic dispersion for 20min;

[0038] (2) Ultrasonic dispersion is taken out and stirred to prevent the powder from sinking to the bottom, then transferred to a three-necked flask, 82ml of deionized water is added, and the mixed solution is heated and stirred with a magnetic stirrer with a water bath;

[0039] (3) When the temperature of the mixed solution rises to 40°C, titrate tetraethyl orthosilicate (TEOS) at a rate of 0.0025ml / s. After the titration, continue stirring and heating for a period of time (about 10 minutes); the amount of TEOS is 9ml.

[0040] (4) After the reaction, the mixture was suction filtered and the powder was collected, and dried in a blast oven at a temperature of 110°C.

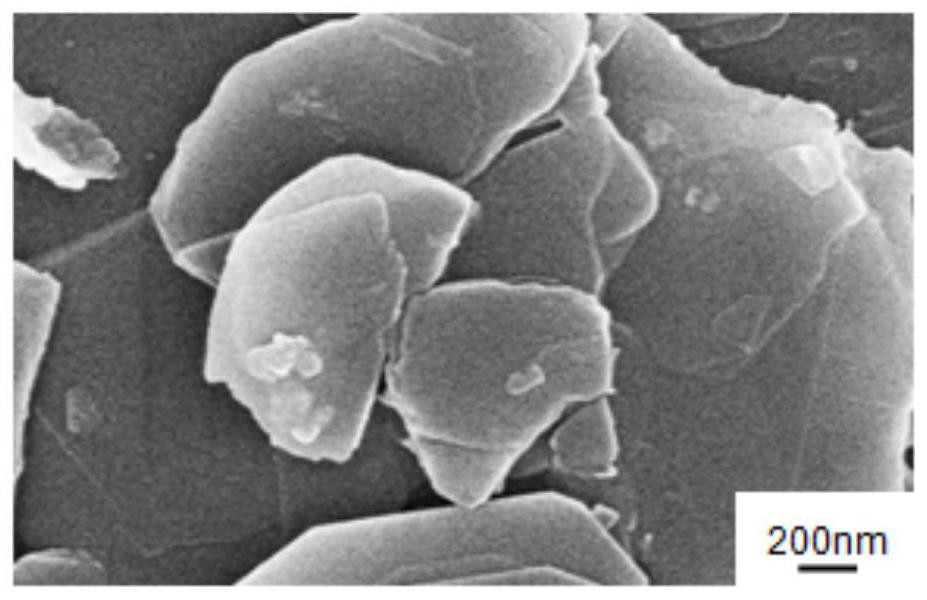

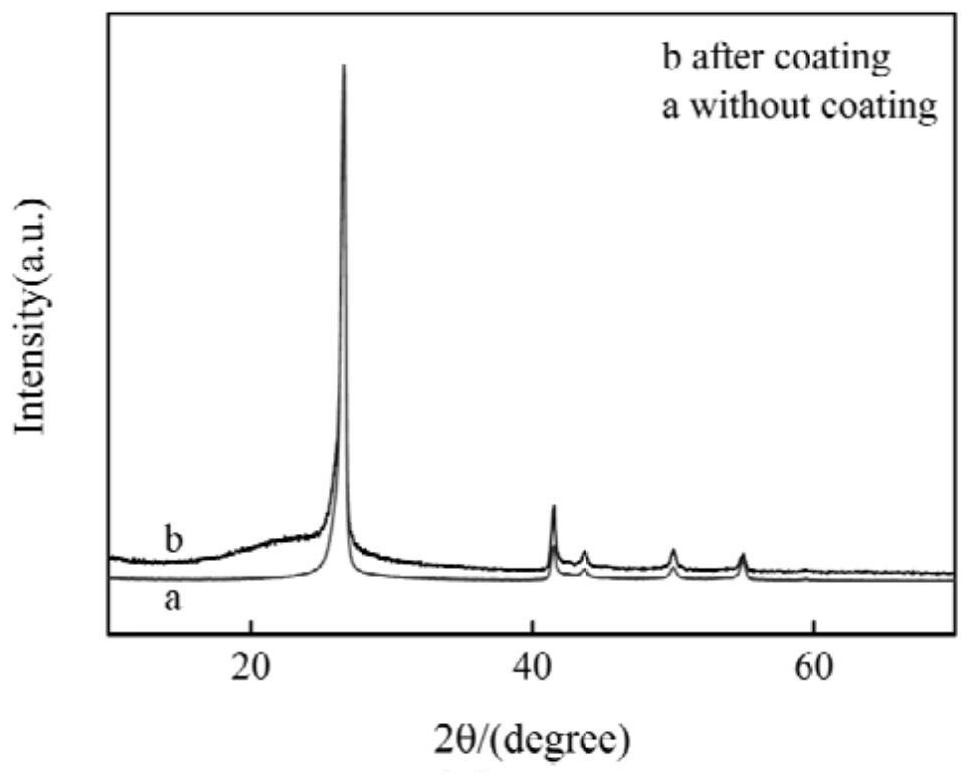

[0041] The prepared powder is analyzed and observed by means of X-ray diffraction, scanning electron microscope, infrared s...

Embodiment 2

[0042] Embodiment 2 Preparation of modified hexagonal boron nitride powder

[0043] (1) Measure 400ml ethanol, 36mL TEOS, 15ml ammonia water, weigh 4g HBN, mix the two and stir with a glass rod, seal with plastic wrap and perform ultrasonic dispersion for 20min;

[0044] (2) Ultrasonic dispersion is taken out and stirred to prevent the powder from sinking to the bottom, then transferred to a three-necked flask, adding 75ml of deionized water and 15ml of ammonia water, and heating and stirring the mixed solution with a magnetic stirrer with a water bath;

[0045] (3) When the temperature of the mixed solution rises to 50°C, titrate tetraethyl orthosilicate at a rate of 0.0020ml / s, and continue stirring and heating for a period of time after the titration is completed;

[0046](4) After the reaction, the mixture was suction filtered and the powder was collected, and dried in a blast oven at 120°C.

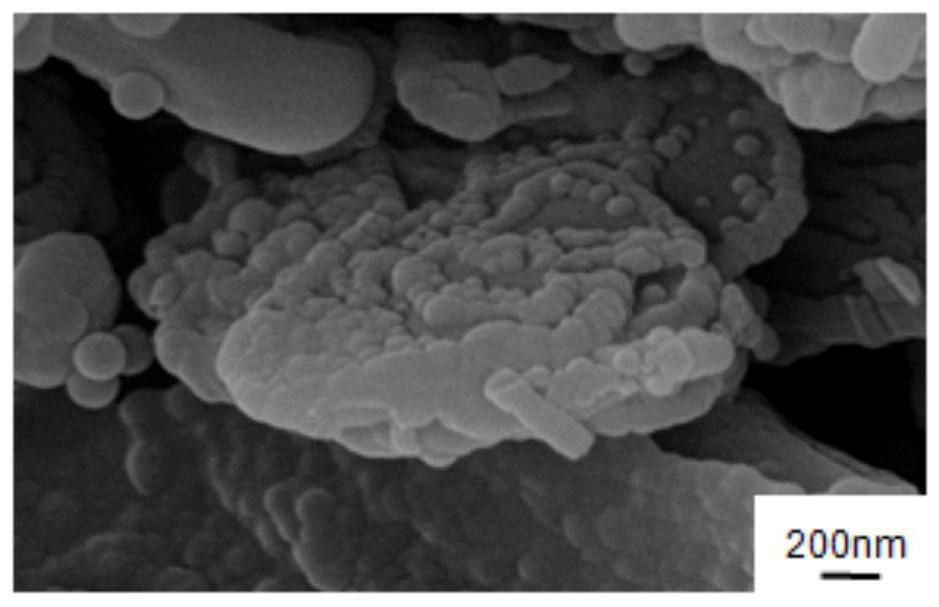

[0047] The prepared powder is analyzed and observed by means of X-ray diffracti...

Embodiment 3

[0049] Embodiment 3 Preparation of modified hexagonal boron nitride powder

[0050] (1) Measure 400ml of ethanol, 36mL of TEOS, 30mL of ammonia water, weigh 4g of HBN, mix the ethanol and HBN and stir with a glass rod, seal with plastic wrap and perform ultrasonic dispersion for 20 minutes;

[0051] (2) Ultrasonic dispersion is taken out and stirred to prevent the powder from sinking to the bottom, then transferred to a three-necked flask, adding 62ml of deionized water and 30ml of ammonia water, and heating and stirring the mixed solution with a magnetic stirrer with a water bath;

[0052] (3) When the temperature of the mixture rises to 60°C, titrate TEOS at a rate of 0.0015ml / s. After the titration, continue to stir and heat for a period of time (about 10 minutes); TEOS36mL;

[0053] (4) After the reaction, the mixture was suction filtered and the powder was collected, and dried in a blast oven at a temperature of 130°C.

[0054] The prepared powder is analyzed and observe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com