Method for preparing polyaluminum chloride from water treatment agent polyaluminum chloride waste slag dechlorination treatment liquid

A polyaluminum chloride waste slag and water treatment agent technology, which is applied in the fields of aluminum chloride, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of ineffective control of eluate concentration, unstable performance of polyaluminum chloride, Energy consumption and other problems, to achieve the perfect crushing process, easy to promote industrialization, to overcome the effect of slipping phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

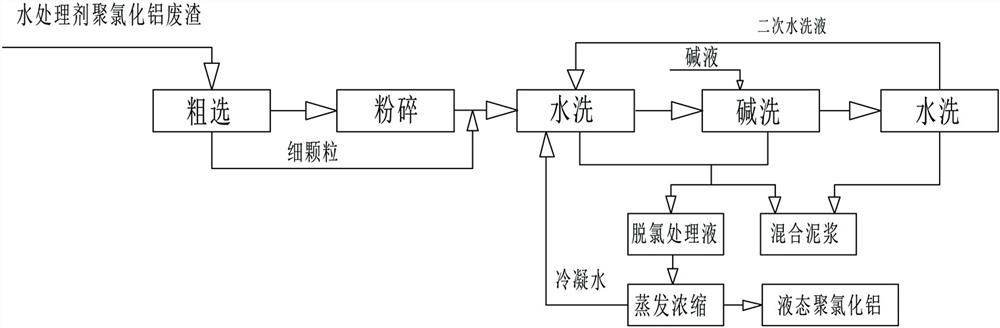

[0028] This embodiment provides a method for producing polyaluminum chloride from water treatment agent polyaluminum chloride waste slag dechlorination treatment liquid, such as figure 1 As shown, it specifically includes the following steps:

[0029] DeCl - Treatment The water treatment agent polyaluminum chloride waste slag is washed with water and treated with lye to obtain dechlorinated treatment liquid and mixed mud, wherein the mass percentage concentration of the lye is controlled to be 10%, and the lye is For sodium hydroxide solution;

[0030] Circulation evaporation The dechlorination treatment solution is placed in a three-effect four-body forced circulation evaporation equipment for circulation evaporation and concentration treatment to obtain 30% Al 2 o 3 of liquid polyaluminum chloride and condensed water.

Embodiment 2

[0032] This embodiment provides a method for producing polyaluminum chloride from water treatment agent polyaluminum chloride waste slag dechlorination treatment liquid, such as figure 2 As shown, the steps are roughly the same as those in Example 1, except that the method provided in this example also includes reclaiming the condensed water, and using the condensed water as a solution to the water treatment agent polychlorinated water. Aluminum waste slag carries out the first water elution of Cl -Water source during treatment; In addition, the mass percent concentration of the lye is 8%.

Embodiment 3

[0034] This embodiment provides a method for producing polyaluminum chloride from water treatment agent polyaluminum chloride waste slag dechlorination treatment liquid, such as image 3 As shown, it specifically includes the following steps:

[0035] The dechlorination ion treatment firstly carries out rough selection to described water treatment agent polyaluminum chloride waste slag and obtains the water treatment agent polyaluminum chloride waste slag with particle diameter greater than 15mm and the water treatment agent polyaluminium chloride waste slag with particle diameter less than 15mm; Then use The differential speed pulverizer crushes the water treatment agent polyaluminum chloride waste slag with a particle size greater than 15mm into a water treatment agent polyaluminum chloride waste slag with a particle size less than 15mm. The water treatment agent polyaluminum chloride waste slag less than 15mm is subjected to the first water elution of Cl in sequence - Trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com