A kind of bio-based nanomaterial and preparation method thereof

A nano-material and bio-based technology, which is applied in the field of bio-based nano-materials and its preparation, can solve the problems of low generation rate and utilization rate of hydroxyl radicals, and achieve the effects of large number of free radicals, simple preparation process and stable reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Grind 5g of bagasse into powder with a mixer and disperse it in 200mL of deionized water, add 15g of sodium persulfate, 3g of iron element and 3g of hydrogen peroxide, stir at 60°C for 2h, then use a cell pulverizer at 30% power for mechanical Treat for 20 minutes, then continue to react at 60° C. for 4 hours to stop the reaction to obtain bagasse hydrolyzate, and the total reaction time is 6 hours.

[0064] After the reaction, use a high-speed centrifuge to centrifuge the bagasse hydrolyzate at a speed of 8000rpm / min for 10 minutes, then take the precipitate and wash it repeatedly with deionized water and centrifuge until the upper layer is in a light blue or milky white suspension state, then dialyze the upper layer to its The pH value is the same or close to the pH value of deionized water, and ultrasonically disperses to obtain a stable dispersed cellulose nanocrystal suspension.

[0065] The measured average length of the obtained cellulose nanocrystals is 563 nm, ...

Embodiment 2

[0067] Grind 5g of bagasse into powder with a blender and disperse in 200mL of deionized water, add 15g of sodium persulfate, 3g of iron element and 3g of hydrogen peroxide, stir at 60°C for 3h, and then use a cell pulverizer at a power of 30% to mechanically Treat for 20 minutes to obtain bagasse hydrolyzate.

[0068] After the reaction, the obtained hydrolyzate is vacuum-filtered, and the precipitate is repeatedly washed and filtered with deionized water until the pH value of the precipitate is close to or the same as that of the deionized water, and a stable dispersed cellulose nanofiber suspension is obtained.

[0069] The measured average length of the obtained cellulose nanofibers was 812 nm, the average diameter was 42 nm, and the yield was 36%.

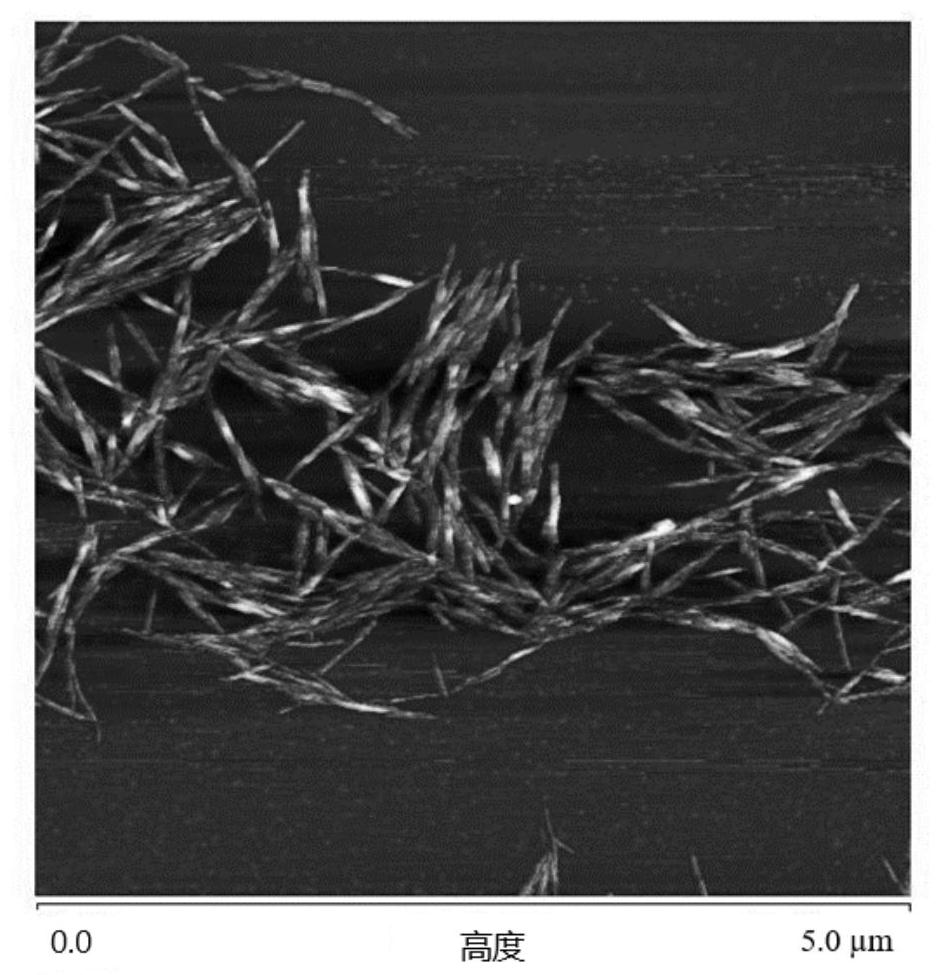

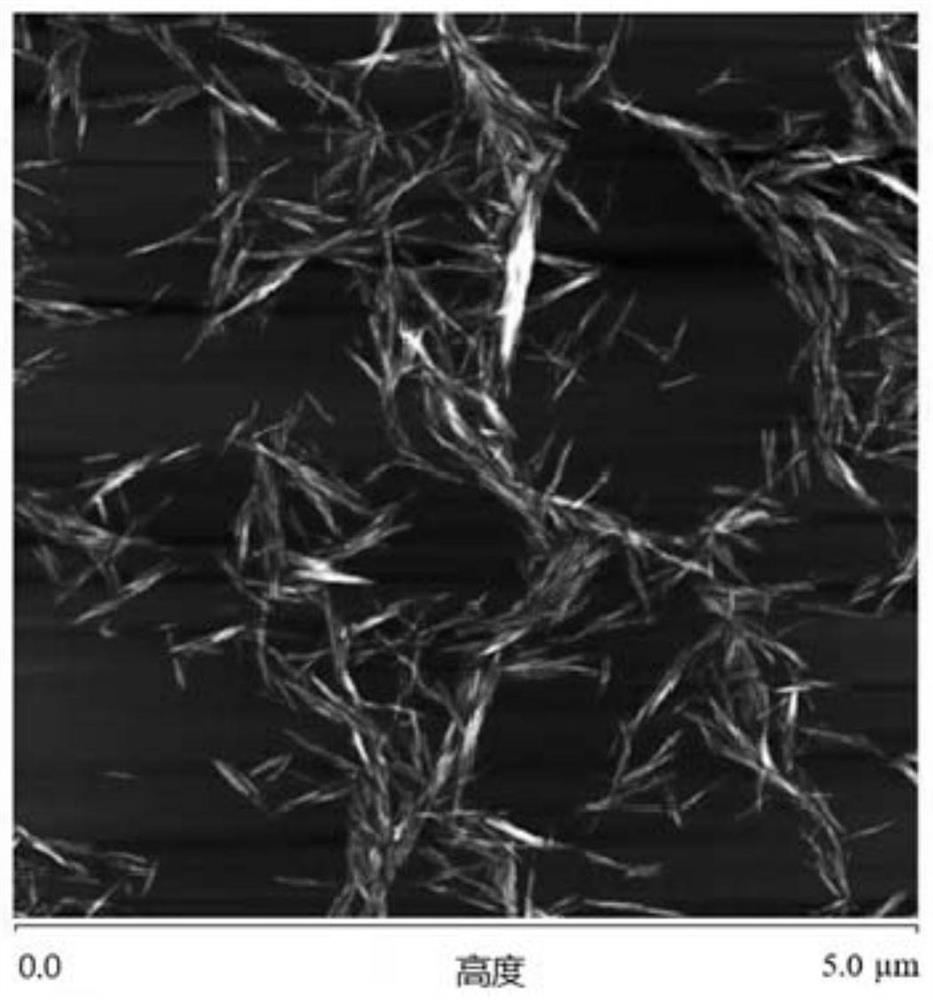

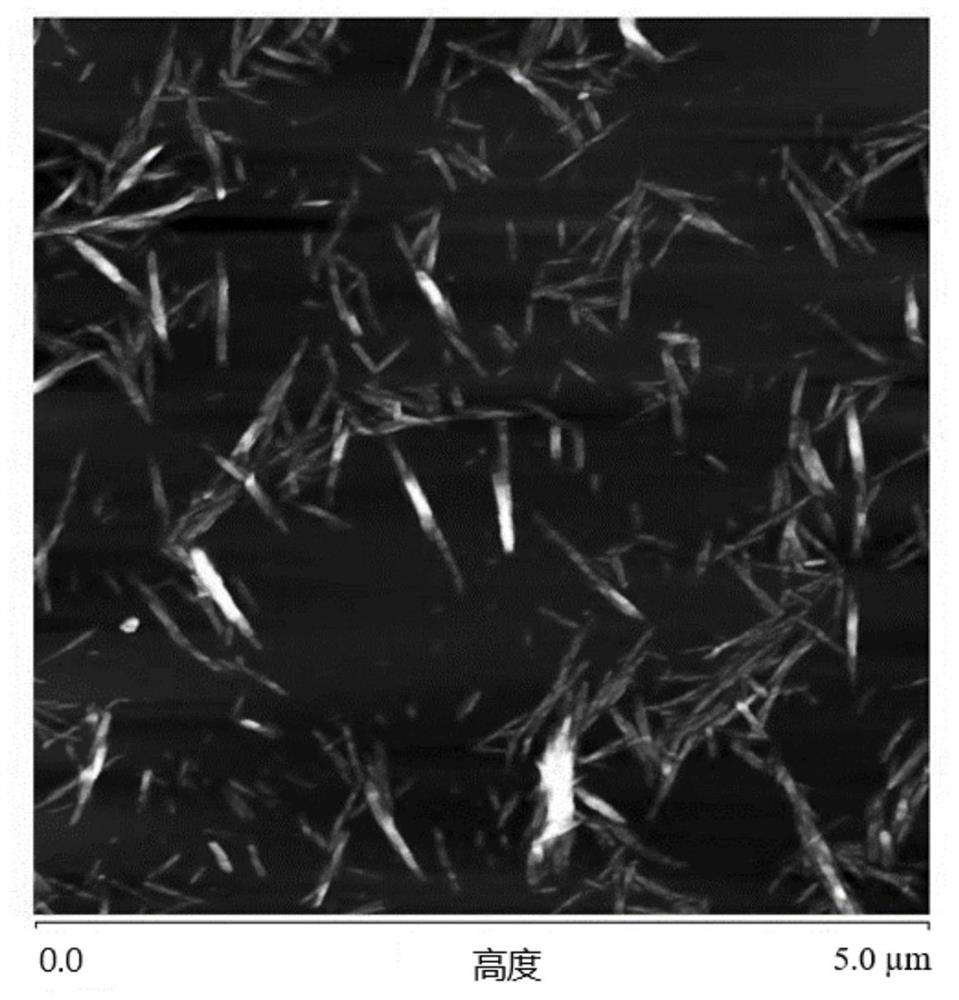

[0070] The morphology distribution of the prepared cellulose nanofibers is as follows: figure 1 ,from figure 1 It can be seen that the cellulose nanofibers prepared by this method have a typical rod-like structure and are ...

Embodiment 3

[0072] Crush 5g of crab shells into powder with a mixer and disperse them in 200mL of deionized water, add 15g of sodium persulfate, 3g of iron element and 3g of hydrogen peroxide, stir at 60°C for 2h, and then use a cell pulverizer at 30% power to process After 20 minutes, continue to react at 60°C for 2 hours to stop the reaction to obtain crab shell powder hydrolyzate, and the total reaction time is 4 hours.

[0073] After the reaction is over, use a high-speed centrifuge to centrifuge the obtained hydrolyzate at a speed of 8000rpm / min for 10min, then take the precipitate and wash it repeatedly with deionized water and centrifuge until the supernatant is in the state of a light blue or milky white suspension, and dialyze the supernatant to its pH The pH is the same as that of deionized water, and ultrasonically dispersed to obtain a stable dispersion of chitin nanocrystal suspension.

[0074] The obtained chitin nanocrystals have an average length of 438 nm, an average diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com