Method for preparing coal-based porous activated carbon material by using cyanamide waste residues as template

A kind of porous activated carbon and activated carbon technology, which is applied in the field of porous carbon materials prepared by hard template method, can solve the problems of no effective utilization of cyanamide waste residue, difficult control of pore structure, pollution of groundwater, etc., and achieve pore expansion and resource utilization, The effect of reducing production costs and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

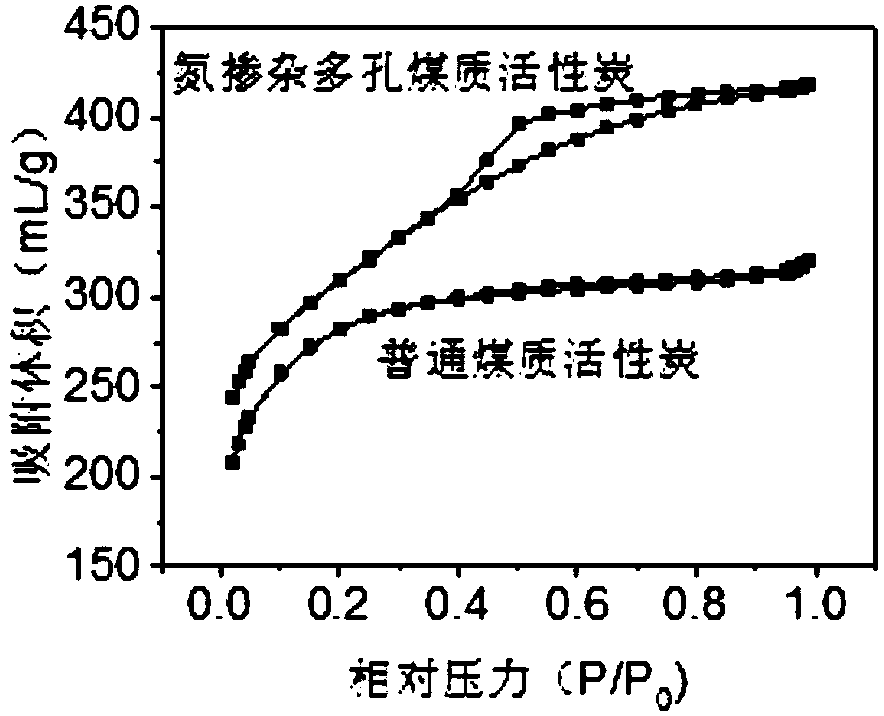

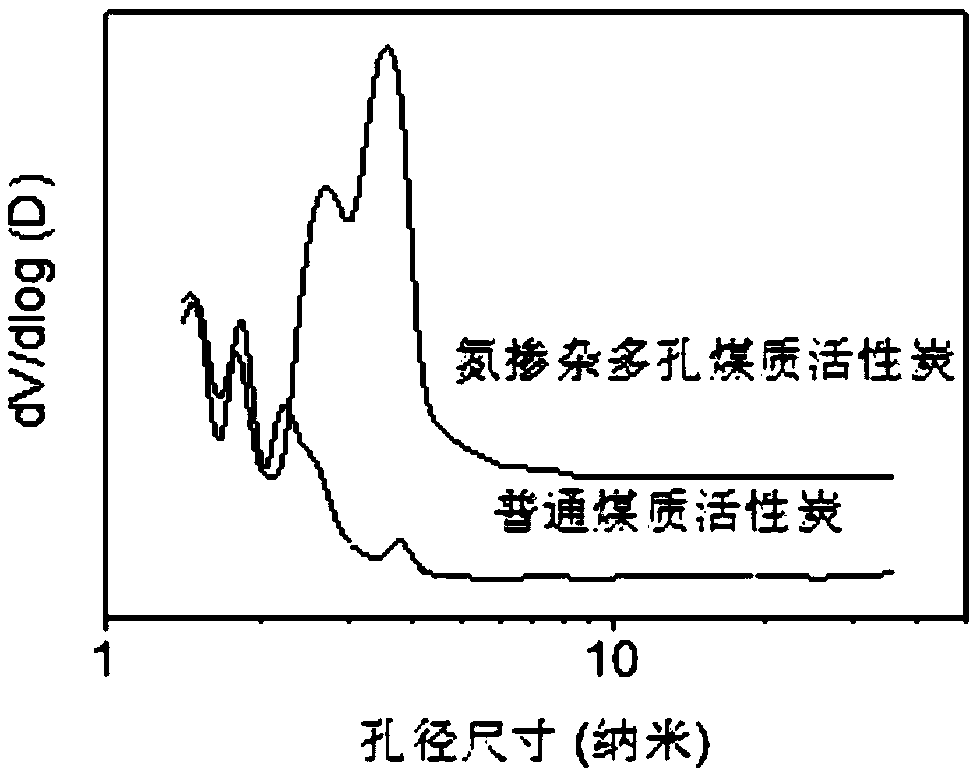

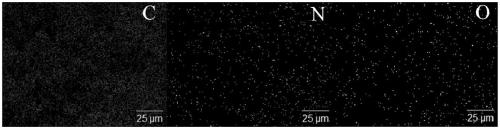

[0036] Crush the raw coal to obtain 60-200 mesh raw coal particles, weigh 100kg of the crushed raw coal particles, 5kg of cyanamide waste residue, 60kg of coal tar and 20kg of water and mix evenly to obtain a mixture; compress the mixture with an extruder, and ventilate and dry it Put it in the pyrolysis tube, feed nitrogen and heat it so that the temperature of the material in the pyrolysis tube reaches 400°C and keep the temperature constant for 2 hours; then stop feeding nitrogen, and feed a flow rate of 0.7 kg / h per kilogram of reaction raw materials Continuously feed water vapor into the pyrolysis tube, keep the temperature at 400°C for 3 hours, then cool to room temperature under nitrogen atmosphere to obtain 22kg of crude activated carbon; add 2.2kg of hydrochloric acid and 110kg of water, pickle at 30°C for 5 hours, and wash with water until the filtrate When the pH is greater than 6, the nitrogen-doped hierarchically porous coal-based activated carbon can be obtained. ...

Embodiment 2

[0040]Crush the raw coal to obtain 60-200 mesh raw coal particles, weigh 100kg of the crushed raw coal particles, 2kg of cyanamide waste residue, 60kg of coal tar and 20kg of water and mix evenly to obtain a mixture; compress the mixture with an extruder, and ventilate and dry it Put it in the pyrolysis tube, feed nitrogen and heat it, so that the temperature of the material in the pyrolysis tube reaches 600 ° C and keep the temperature constant for 3 hours; then stop feeding nitrogen, and feed the amount of flow rate of 0.8 kg / h per kilogram of reaction raw materials Continuously feed water vapor into the pyrolysis tube, keep the temperature at 600°C for 3 hours, then cool to room temperature under nitrogen atmosphere to obtain 22kg of crude activated carbon; add 2.2kg of hydrochloric acid and 110kg of water, pickle at 30°C for 5 hours, and wash with water until the filtrate When the pH is greater than 6, the nitrogen-doped hierarchically porous coal-based activated carbon can...

Embodiment 3

[0042] Crush the raw coal to obtain 60-200 mesh raw coal particles, weigh 100kg of crushed raw coal particles, 8kg of cyanamide waste residue, 60kg of coal tar and 20kg of water and mix them evenly to obtain a mixture; compress the mixture with an extruder, and ventilate and dry it Put it in the pyrolysis tube, feed nitrogen and heat it, so that the temperature of the material in the pyrolysis tube reaches 800°C and keep the temperature constant for 10 hours; then stop feeding nitrogen, and feed a flow rate of 1.2 kg / h per kilogram of reaction raw materials Continuously feed CO into the pyrolysis tube 2 Gas, after constant temperature at 800°C for 3h, in CO 2 Cool to room temperature under atmosphere to obtain 22kg of crude activated carbon; add 2.2kg of hydrochloric acid and 110kg of water, pickle at 30°C for 5 hours, wash with water until the pH of the filtrate is greater than 6, and obtain nitrogen-doped hierarchically porous coal-based activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com