Preparation method of catalyst for ultraviolet catalytic wet-type oxidation

A technology for catalytic wet oxidation and catalyst, which is applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. and other problems, to achieve the effect of high catalytic efficiency, strong redox ability, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of the catalyst of the present embodiment is carried out as follows:

[0027] (1) Accurately measure La(NO 3 ) 3 ·nH 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of distilled water to form a mixed solution with a solute mass concentration of 10%;

[0028] (2) Add citric acid (the molar ratio of citric acid to metal ion is 3:1) to the mixed solution and stir until completely dissolved to form a sol;

[0029] (3) drying at 90°C to form a gel;

[0030] (4) Grinding the gel through a 100-mesh sieve for subsequent use;

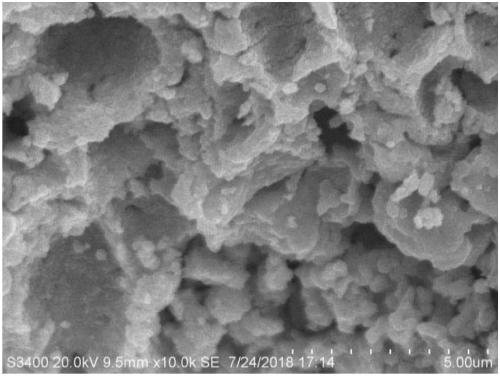

[0031] (5) Calcined at 700°C for 5h to obtain LaCoO 3 Perovskite type catalyst; The X-ray diffraction figure and the scanning electron microscope figure of gained catalyst are respectively as figure 1 and figure 2 shown.

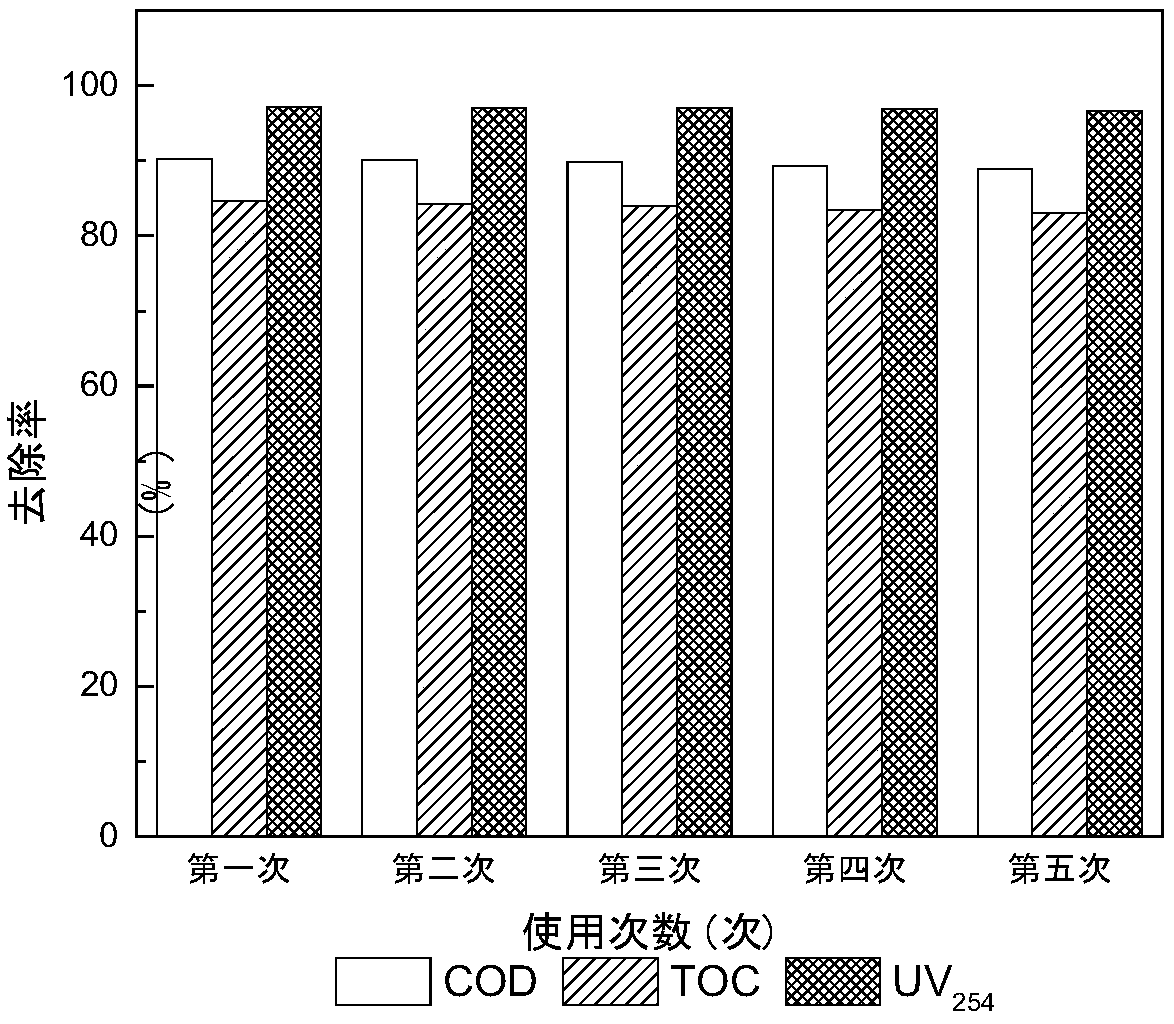

[0032] Using the catalyst prepared in this example, a certain coal gasification membrane concentrate is used as the treatment object, and it is treated by ultraviolet-catalytic wet hydrogen perox...

Embodiment 2

[0036] The preparation of the catalyst of the present embodiment is carried out as follows:

[0037] (1) Accurately measure La(NO 3 ) 3 ·nH 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of distilled water to form a mixed solution with a solute mass concentration of 15%;

[0038] (2) Add citric acid (the molar ratio of citric acid to metal ion is 2:1) to the mixed solution and stir until completely dissolved to form a sol;

[0039] (3) drying at 100°C to form a gel;

[0040] (4) Grinding the gel through a 100-mesh sieve for subsequent use;

[0041] (5) Calcined at 800°C for 6h to obtain LaCoO 3 perovskite catalysts.

Embodiment 3

[0046] The preparation of the catalyst of the present embodiment is carried out as follows:

[0047] (1) Accurately measure La(NO 3 ) 3 ·nH 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of distilled water to form a mixed solution with a solute mass concentration of 20%;

[0048] (2) Add citric acid (the molar ratio of citric acid to metal ion is 3:2) to the mixed solution and stir until completely dissolved to form a sol;

[0049] (3) drying at 110°C to form a gel;

[0050] (4) Grinding the gel through a 100-mesh sieve for subsequent use;

[0051] (5) Calcined at 900°C for 7h to obtain LaCoO 3perovskite catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com