Low-coking type catalytic cracking catalyst and preparation method thereof

A catalytic cracking, low-coking technology, applied in the direction of catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problems of low B/L acid ratio and undeveloped pore structure, etc., to reduce coke, reduce Effect of low coke yield and coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The technical solutions of the present invention will be further described below through examples.

[0037] 1. Main analysis methods

[0038] Table 1 The main analytical methods involved in the present invention

[0039] project

method

Standard Code

RE 2 o 3 ,m%

XRF method

/

Na 2 o

XRF method

/

Pore volume, cm 3 .g -1

water drop method

Q / SYLS0521-2002

[0040] 2. Catalyst evaluation:

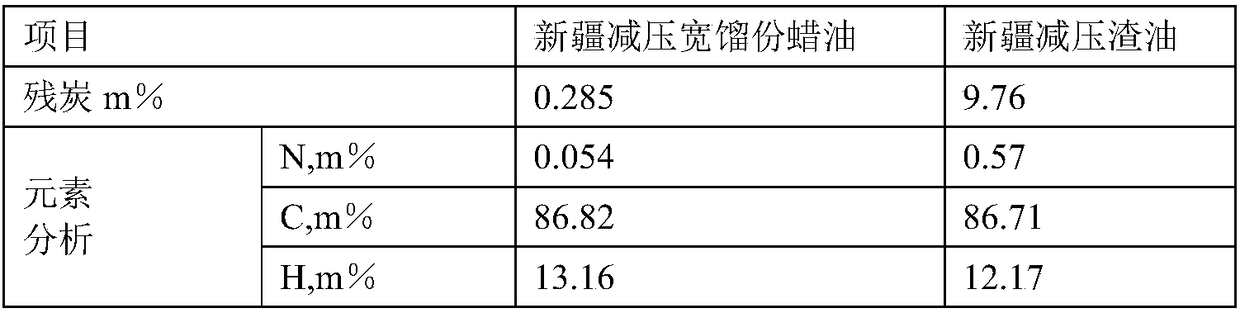

[0041] The reaction performance was evaluated by ACE device, and the raw oil used was Xinjiang vacuum wide-distillation wax oil and Xinjiang vacuum residue, and the residue ratio was 30%. The properties of raw oil are shown in Table 2. The catalyst was aged at 800°C and 100% steam for 17 hours before evaluation.

[0042] Table 2 Catalyst Selectivity Evaluation Raw Oil Properties

[0043]

[0044]

Embodiment 1

[0046] Si-alumina material preparation

[0047] Take 20.1ml NaY zeolite directing agent and mix with 36ml 250g / l water glass evenly, add water to dilute to SiO 2 The concentration is 60g / L (as SiO 2 (the same below), raise the temperature to 70°C, add 4mol / L hydrochloric acid dropwise under strong stirring until the pH value of the system = 7, and continue aging at constant temperature for 2 hours under stirring; after aging, add 4mol / L hydrochloric acid dropwise to the pH Value = 5, then slowly add 1.6ml 90g / L (A1 2 o 3 After the addition, continue to stir for 1 hour; add ammonia water to adjust the pH to 8, raise the temperature to 85°C, and keep stirring for 1 hour. After the obtained product is filtered and washed, the resulting solid precipitate is ion-exchanged according to ammonium chloride: solid precipitate (dry basis): water = 1:0.3:6 to remove sodium ions, and the exchange is repeated twice, each time for 0.5h After each exchange, wash and filter with water, the...

Embodiment 2

[0056] Si-alumina material preparation

[0057] Take 12.1ml NaY zeolite directing agent and 26.8ml tetraethyl orthosilicate, mix evenly, add water to dilute to SiO 2 The concentration is 40g / L, the temperature is raised to 60°C, and 6mol / L sulfuric acid is added dropwise under strong stirring until the pH value of the system = 8, and the constant temperature aging is continued for 1.5h under stirring; after aging, 6mol / L sulfuric acid is added dropwise to pH value = 4, then slowly add 3.9ml 90g / L aluminum chloride solution under stirring conditions, continue stirring for 2 hours after the addition is complete; add 10wt% sodium hydroxide solution to adjust pH value = 7, raise the temperature to 90 ° C, keep stirring at a constant temperature of 1.5 h. After the obtained product is filtered and washed, the resulting solid precipitate is ion-exchanged according to ammonium nitrate: solid precipitate (dry basis): water = 1:0.5:8 to remove sodium ions, and the exchange is repeated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com