Three-dimensional sea urchin-like/porous composite structure lithium ion battery Cu/CuO/SnO2/C anode and preparation method thereof

A lithium-ion battery and tin dioxide technology, which is applied to battery electrodes, secondary batteries, structural parts, etc., can solve problems that are not conducive to large-scale production of production costs, cumbersome production processes, and limited binding force, and achieve improved constant current. Charge-discharge cycle stability, ease volume expansion effect, and improve electrode conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

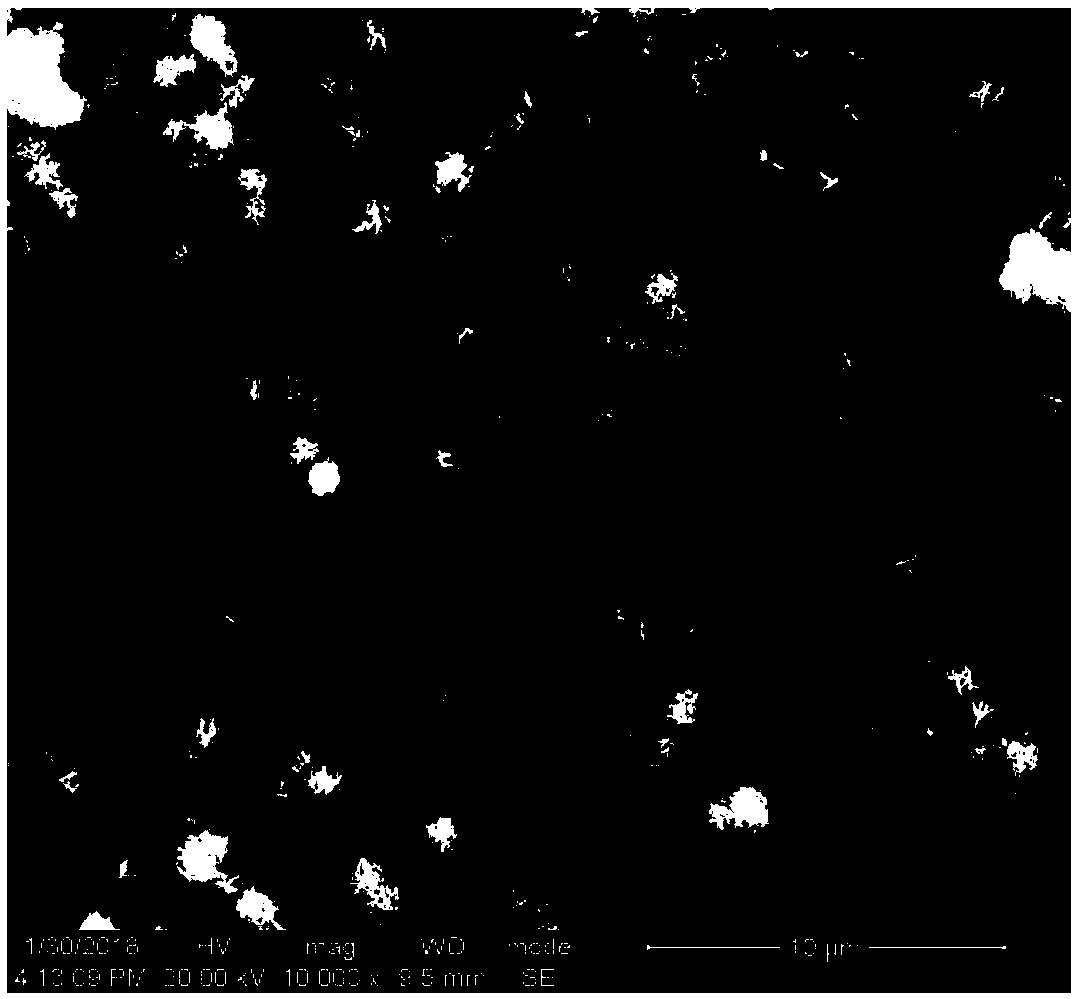

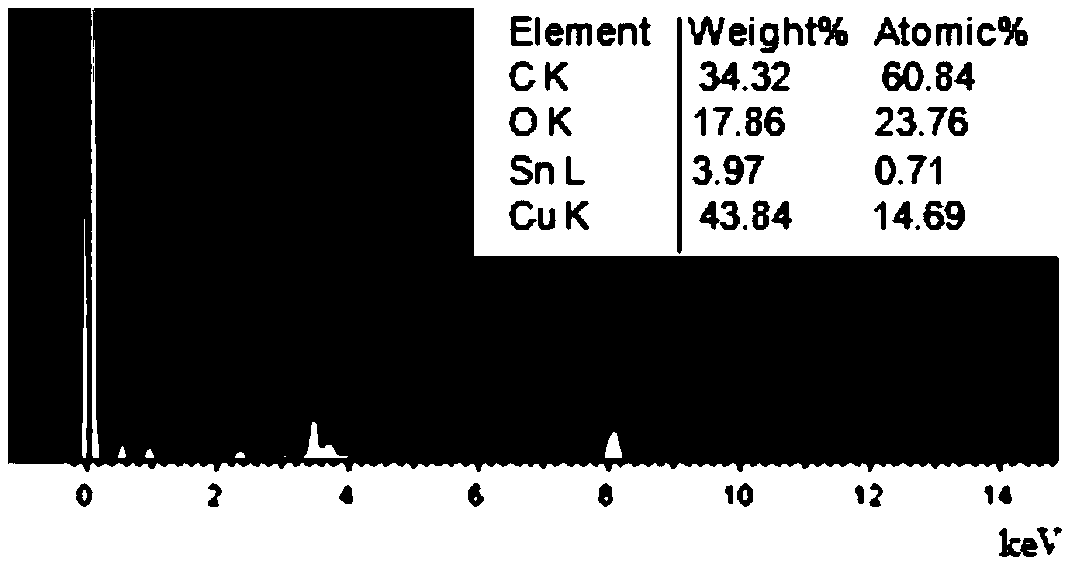

[0044] In this embodiment, a three-dimensional sea urchin / porous composite structure lithium-ion battery Cu / CuO / SnO is provided 2 The preparation method of / C negative electrode, the steps are as follows:

[0045] (1) Weigh the copper block and the aluminum block according to the atomic percentage of copper and aluminum being 35:65, and melt them in a muffle furnace to obtain a copper-aluminum alloy ingot. Cut the copper-aluminum alloy ingot with a wire cutting machine into copper-aluminum alloy sheets with a thickness of 600 μm and a length and width of 7 mm, and then use 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper to sand the surface of the copper-aluminum alloy sheet. Grinding, and then polishing with a metallographic sample polishing machine, cleaning the polished copper-aluminum alloy sheet with deionized water, and then placing it in 5wt.% hydrochloric acid for dealloying treatment, the dealloying treatment time is 5h, and passing through a water bath C...

Embodiment 2

[0052] In this embodiment, a three-dimensional sea urchin / porous composite structure lithium-ion battery Cu / CuO / SnO is provided 2 The preparation method of / C negative electrode, the steps are as follows:

[0053](1) Weigh the copper block and the aluminum block according to the atomic percentage of copper and aluminum being 30:70, and melt them in a muffle furnace to obtain a copper-aluminum alloy ingot. Cut the copper-aluminum alloy ingot with a wire cutting machine into copper-aluminum alloy sheets with a thickness of 600 μm and a length and width of 7 mm, and then use 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper to sand the surface of the copper-aluminum alloy sheet. Grinding, and then polishing with a metallographic sample polishing machine, cleaning the polished copper-aluminum alloy sheet with deionized water, and then placing it in 8wt.% hydrochloric acid for dealloying treatment, the dealloying treatment time is 4h, passing through a water bath The de...

Embodiment 3

[0060] In this embodiment, a three-dimensional sea urchin / porous composite structure lithium-ion battery Cu / CuO / SnO is provided 2 The preparation method of / C negative electrode, the steps are as follows:

[0061] (1) Weigh a copper block and an aluminum block according to the atomic percentage of copper and aluminum being 50:50, and melt them in a muffle furnace to obtain a copper-aluminum alloy ingot. Cut the copper-aluminum alloy ingot with a wire cutting machine into copper-aluminum alloy sheets with a thickness of 400 μm and a length and width of 7 mm, and then use 380-mesh, 800-mesh, 1200-mesh, and 2000-mesh water sandpaper to sand the surface of the copper-aluminum alloy sheet. Grinding, and then polishing with a metallographic sample polishing machine, cleaning the polished copper-aluminum alloy sheet with deionized water, and then placing it in 1wt.% hydrochloric acid for dealloying treatment, the dealloying treatment time is 10h, passing through a water bath The dea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com