Preparation method for silicon carbon composite material for lithium ion battery negative electrode

A technology for lithium ion batteries and composite materials, which is applied in the field of preparation of silicon carbon-based composite materials for lithium ion battery negative electrodes, can solve the problems of insignificant relief of expansion effect, decreased cycle performance, detachment of active materials, etc., and achieves prevention of agglomeration effect, Stable and evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

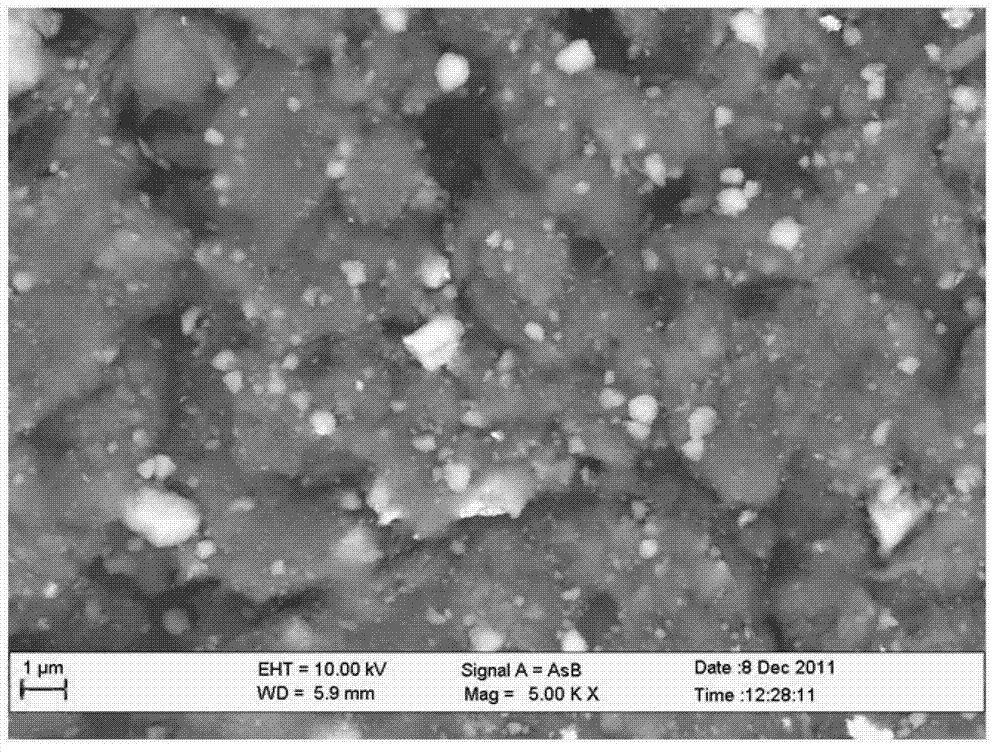

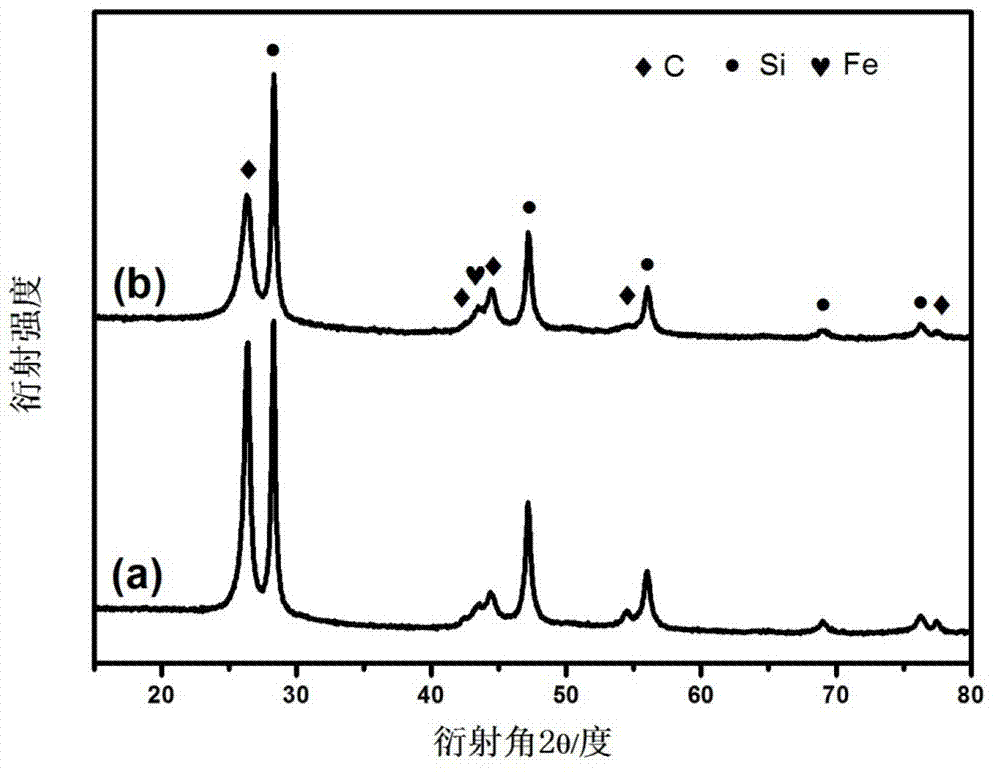

[0032] The preparation method of the silicon-carbon-based composite material for the lithium-ion battery negative electrode of the present embodiment is as follows:

[0033] The first step of ball milling: add anhydrous ethanol grinding aid with a mass of 2% of the mass of the elemental silicon to the elemental silicon, and use dielectric barrier discharge plasma-assisted high-energy ball milling method for ball milling, wherein the mass ratio of grinding balls to elemental silicon is 30:1 , the milling time is 10h;

[0034] The second step of ball milling: mix the silicon powder and carbon raw material powder obtained in the first step of ball milling, wherein the mass ratio of silicon powder and carbon raw material is 1:4, add anhydrous ethanol with a mass of 2% of the total mass of the abrasive, and use a medium Barrier discharge plasma-assisted high-energy ball milling method ball milling, wherein the ratio of balls to the total mass of silicon powder and carbon raw materi...

Embodiment 2

[0043] The preparation method of the silicon-carbon-based composite material for the lithium-ion battery negative electrode in this embodiment is the same as that in Embodiment 1, except that the ball milling time in the second step of ball milling is 10 h.

[0044] The test results show that the composite material Si prepared in this embodiment 20 C 80The first reversible capacity is 953.2mAh / g. The discharge capacity remained at 582.9mAh / g after 85 cycles.

Embodiment 3

[0046] The preparation method of the silicon-carbon-based composite material for lithium ion battery negative electrode of the present embodiment, except that the quality of the grinding aid of the first step ball milling is 1% of the mass of elemental silicon; the quality of the grinding aid of the second step ball milling is mixed silicon powder and 1% of the total mass of the carbon raw material powder, and the ratio of the mass of the grinding ball to the total mass of the silicon powder and the carbon raw material powder is 70:1, and the rest are the same as in Example 1.

[0047] The test results show that the composite material Si prepared in this embodiment 20 C 80 The initial reversible capacity is 938.4mAh / g, and the discharge capacity remains at 432.8mAh / g after 85 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com