Epoxy acrylic cathode electrophoretic coating resin emulsion and preparation method thereof

A cathodic electrophoretic coating, epoxy acrylic technology, applied in electrophoretic coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve problems such as poor compatibility between epoxy resin and acrylic resin, reduce coating costs, and simplify coating. Process, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

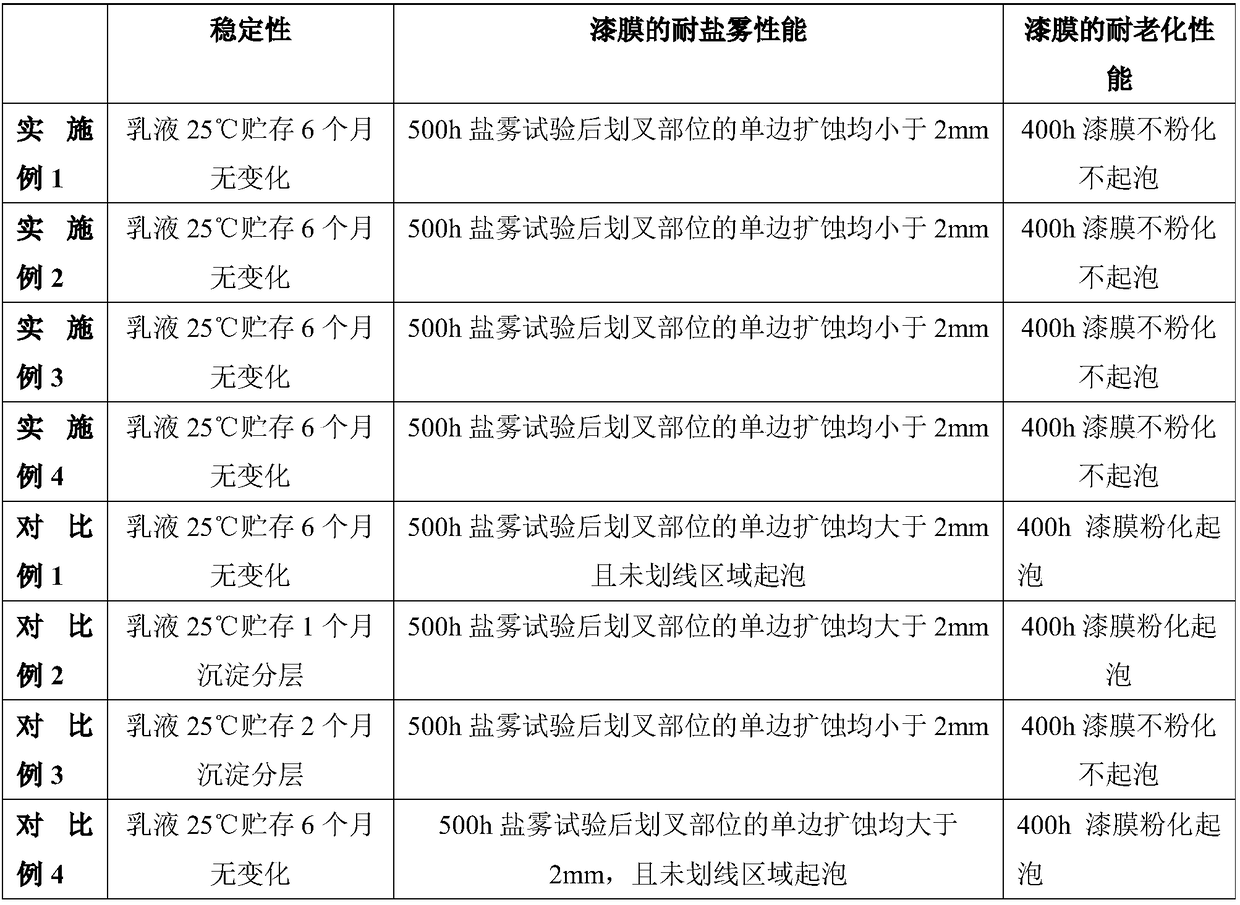

Examples

Embodiment 1

[0021] A kind of preparation method of epoxy acrylic cathodic electrophoretic coating resin emulsion, concrete preparation steps are as follows:

[0022] (1) Preparation of acrylic resin containing reactive functional groups: Add 25g of tetrahydrofuran into a reaction flask equipped with an electric stirrer, reflux condensing device, and thermometer, start stirring and heat up to 80°C; add 80g of 2-fluoroacrylic acid dropwise , 25g N-methacrylamide, 243g heptafluorobutyl acrylate, 219g isopropyl methacrylate, 150g isobornyl methacrylate, 238g hexyl acrylate, 20g benzoyl peroxide mixture, within 3.5 hours After completion of the dropwise addition, heat preservation reaction for 2.5 hours, add an appropriate amount of initiator benzoyl peroxide, continue heat preservation reaction for 2 hours after the completion of the dropwise addition to prepare an acrylic resin containing reactive functional groups, and the average molecular weight of the resin is 6800;

[0023] (2) Preparat...

Embodiment 2

[0025]A kind of preparation method of epoxy acrylic cathodic electrophoretic coating resin emulsion, concrete preparation steps are as follows:

[0026] (1) Preparation of acrylic resin containing reactive functional groups: Add 40g of n-propanol in a reaction flask equipped with an electric stirrer, reflux condensing device, and thermometer, start stirring and heat up to 75°C, add dropwise 98g of 2- Methyl acetamidoacrylate, 102g methyl 2-hydroxymethacrylate, 197g ethyl methacrylate, 266g isobutyl acrylate, 237g cyclohexyl methacrylate, 48g isooctyl acrylate, 12g azobisisobutyrocyanide The mixed solution was added dropwise within 3 hours, and the heat preservation reaction was carried out for 3 hours, and an appropriate amount of initiator azobisisobutylcyanide was added. After the dropwise addition, the heat preservation reaction was continued for 1.5 hours to prepare an acrylic resin containing reactive functional groups, and the average molecular weight of the resin was is...

Embodiment 3

[0029] A kind of preparation method of epoxy acrylic cathodic electrophoretic coating resin emulsion, concrete preparation steps are as follows:

[0030] (1) Preparation of acrylic resin containing reactive functional groups: Add 30 g of isopropanol to a reaction bottle equipped with an electric stirrer, reflux condensing device, and thermometer, start stirring and heat up to 90° C., dropwise add 60 g of acrylic acid, A mixture of 100g hydroxyethyl acrylate, 200g methyl methacrylate, 398g butyl acrylate, 202g styrene, and 10g benzoyl peroxide was added dropwise within 4 hours. Benzoyl oxidation, after the dropwise addition, continue to keep warm for 1 hour to prepare an acrylic resin containing reactive functional groups, and the mass average molecular weight of the obtained resin is 4233;

[0031] (2) Preparation of epoxy acrylic cathodic electrophoretic coating resin emulsion: Add low molecular weight epoxy resin with epoxy equivalent of 235, bisphenol A, and propylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com