Preparation method of novel nanocrystallized sericite powder

A sericite powder and nanotechnology, which is applied in the field of preparation of new nano-sericite powder, can solve the problems of whiteness, smoothness, insufficient skin-adhesiveness, and poor compatibility, and achieve suitable large-scale production and high whiteness. The effect of high degree and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

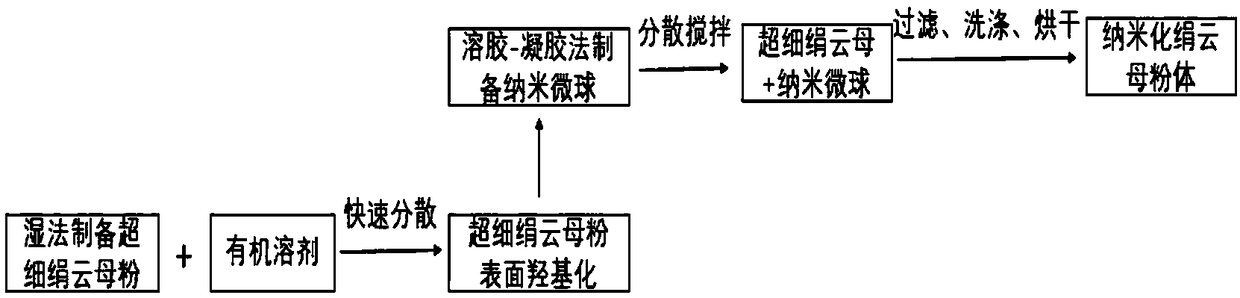

[0028] Weigh 20g of ultra-fine sericite powder prepared by wet method, add it to 30ml of deionized water and 60ml of simethicone mixed solution, stir and disperse at 50°C for 2h at high speed to form hydroxylated sericite powder for use.

[0029] Measure 10ml of hexamethyldisiloxane, add it to the mixed solution of 350ml of water and ethanol, stir and disperse evenly, then add 0.25g of octadecylaminotrimethylammonium chloride and continue stirring for 30min until the dispersion is even, add A certain amount of tartaric acid is used to adjust the pH of the reaction system to 5.5±0.5. Under this system, continue to stir rapidly for 10 hours, then add the above-mentioned hydroxylated sericite powder into it, and continue to disperse and stir at a high speed for 6 hours at 50°C. Subsequently, the coated sericite slurry is filtered, washed and dried to obtain nanometerized sericite powder.

Embodiment 2

[0031] Weigh 25g of ultra-fine sericite powder prepared by wet method, add it to 40ml of deionized water and 50ml of simethicone mixed solution, stir and disperse at 50°C for 2h at high speed to form hydroxylated sericite powder for use.

[0032] Measure 10ml of hexamethyldisiloxane, add it to the mixed solution of 350ml of water and ethanol, stir and disperse evenly, then add 0.25g of octadecylaminotrimethylammonium chloride and continue stirring for 30min until the dispersion is even, add A certain amount of tartaric acid is used to adjust the pH of the reaction system to 5.5±0.5. Under this system, continue to stir rapidly for 10 hours, then add the above-mentioned hydroxylated sericite powder into it, and continue to disperse and stir at a high speed for 6 hours at 50°C. Subsequently, the coated sericite slurry is filtered, washed and dried to obtain nanometerized sericite powder.

Embodiment 3

[0034] Weigh 20g of ultra-fine sericite powder prepared by wet method, add it to 30ml of deionized water and 60ml of simethicone mixed solution, stir and disperse at 50°C for 2h at high speed to form hydroxylated sericite powder for use.

[0035] Measure 10ml of hexamethyldisiloxane, add it to the mixed solution of 550ml of water and ethanol, stir and disperse evenly, then add 0.35g of octadecylaminotrimethylammonium chloride and continue stirring for 30min until the dispersion is even, add A certain amount of tartaric acid is used to adjust the pH of the reaction system to 5.5±0.5. Under this system, continue to stir rapidly for 10 hours, then add the above-mentioned hydroxylated sericite powder into it, and continue to disperse and stir at a high speed for 6 hours at 50°C. Subsequently, the coated sericite slurry is filtered, washed and dried to obtain nanometerized sericite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com