High-viscosity asphalt modifier and preparation method and application thereof

An asphalt modifier and high-viscosity technology, used in building components, building insulation materials, buildings, etc., can solve problems such as resilience and poor high and low temperature performance, and achieve high wear resistance, high hardness, and guaranteed strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

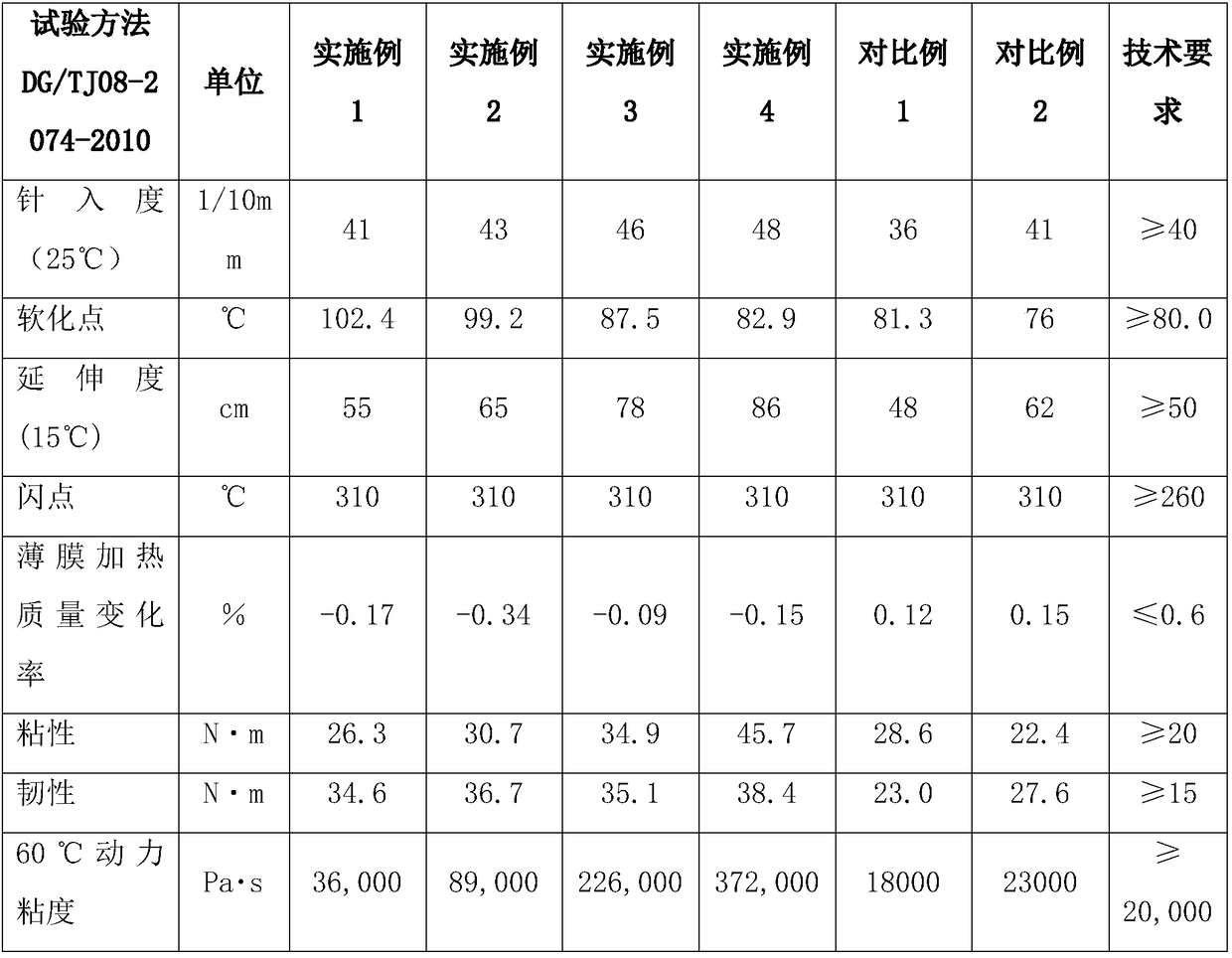

Examples

Embodiment 1

[0027] ① 0.5 parts of silane coupling agent and 5 parts of composite organic filler were mixed in a high-speed mixer for 20 minutes at a speed of 400 rpm to obtain material 1;

[0028] ② Mix 50 parts of sarin resin, 40 parts of POK, 5 parts of M-SEBS and 0.5 parts of lubricant in a high-speed mixer at a speed of 300 rpm for 5 minutes, then add 0.5 parts of antioxidant and 0.3 parts of accelerator , continue to mix, the rotating speed is 300rpm, the time is 5min, obtains material 2;

[0029] ③Put material 2 in step ② from the main feed port and step ① material 1 from the side feed port into the parallel twin-screw extruder for granulation. Granules were dried at 80°C for 4 hours to obtain a high-viscosity asphalt modifier.

Embodiment 2

[0031] ① 1 part of silane coupling agent and 10 parts of composite organic filler were mixed in a high-speed mixer for 20 minutes at a speed of 600 rpm to obtain material 1;

[0032] ② Mix 60 parts of sarin resin, 20 parts of POK, 10 parts of M-SEBS and 0.5 parts of lubricant in a high-speed mixer at a speed of 300 rpm for 5 minutes, then add 0.5 parts of antioxidant and 0.3 parts of accelerator , continue to mix, the rotating speed is 300rpm, the time is 5min, obtains material 2;

[0033] ③Put material 2 in step ② from the main feed port and step ① material 1 from the side feed port into the parallel twin-screw extruder for granulation. Granules were dried at 80°C for 4 hours to obtain a high-viscosity asphalt modifier.

Embodiment 3

[0035] ① 1.5 parts of silane coupling agent and 15 parts of composite organic filler were mixed in a high-speed mixer for 20 minutes at a speed of 800 rpm to obtain material 1;

[0036] ② Mix 70 parts of sarin resin, 10 parts of POK, 5 parts of M-SEBS and 0.5 parts of lubricant in a high-speed mixer at a speed of 300 rpm for 5 minutes, then add 0.5 parts of antioxidant and 0.3 parts of accelerator , continue to mix, the rotating speed is 300rpm, the time is 5min, obtains material 2;

[0037] ③Put material 2 in step ② from the main feed port and step ① material 1 from the side feed port into the parallel twin-screw extruder for granulation. Granules were dried at 80°C for 4 hours to obtain a high-viscosity asphalt modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com