Low-gloss low-odor ABS resin composition for automobile interior and preparation method thereof

A technology for ABS resin and automotive interior decoration, which is applied in the field of low gloss and low odor ABS resin composition for automotive interior and its preparation, can solve the problems of low gloss, glossy odor, low odor, etc., and achieves reduction of material odor and gloss. degree, the effect of reducing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

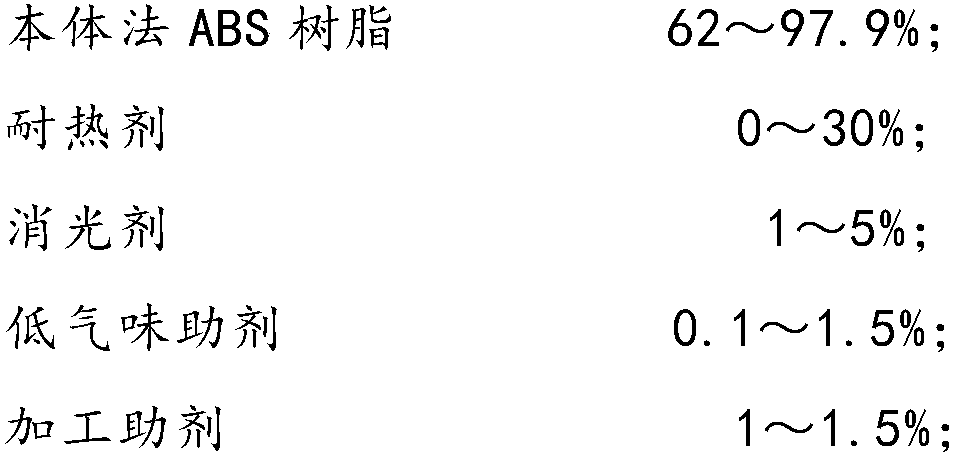

Method used

Image

Examples

Embodiment 1~5 and comparative example l~3

[0029] After the dry ABS resin, heat-resistant agent, matting agent, low-odor additive, antioxidant, light stabilizer, lubricant are mixed by the composition formula in Table 1, join the twin-screw extruder (screw diameter is 35mm , aspect ratio L / D=48) in the main barrel. The temperature control of each section of the main barrel (from the feeding port to the exit of the machine head) is 220°C, 220°C, 230°C, 230°C, 230°C, the twin-screw speed is 350 rpm, and the extruded material is cut after cooling in the water tank. grains, the sample is obtained.

[0030] Table 1 embodiment 1~5 and comparative example 1~3 composition formula

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com