Molybdenum sulfide flexible electrode material and preparation method and application thereof

A flexible electrode and molybdenum sulfide technology, applied in nanotechnology for materials and surface science, battery electrodes, hybrid capacitor electrodes, etc., can solve the problems of broken cotton cloth, difficult to maintain shape, high synthesis temperature, etc., to reduce the generation temperature , Excellent electrochemical performance, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

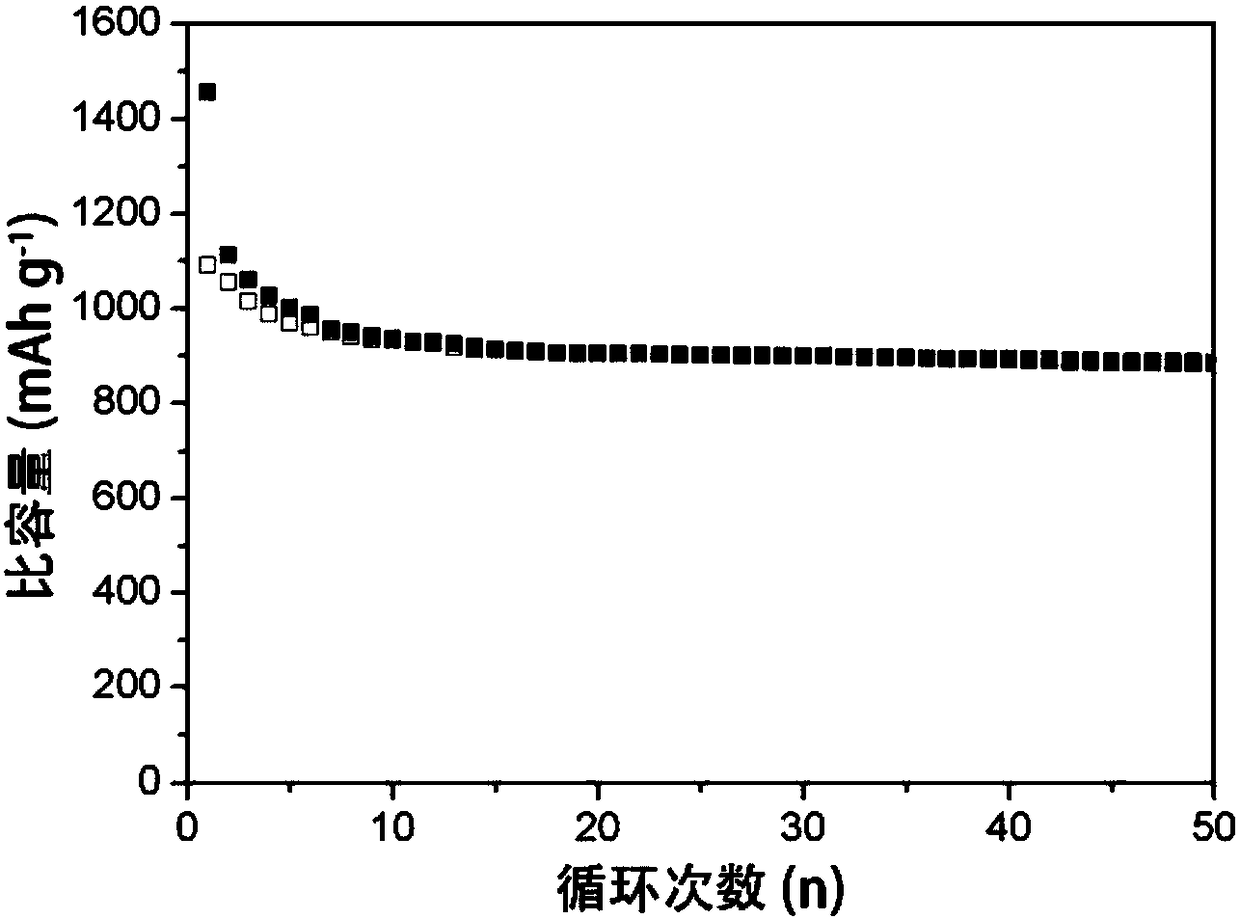

Examples

Embodiment 1

[0045] (1) Splash a layer of gold on the surface of the cotton cloth, the mass ratio of gold to cotton cloth is 1:5;

[0046] (2) the material that step (1) is obtained is mixed with ammonium molybdate, ammonium fluoride and urea, wherein the mass ratio of cotton cloth and ammonium molybdate is 1:1, and the mol ratio of ammonium molybdate, ammonium fluoride and urea is 1:2:4, transfer the mixture to a closed reaction kettle, heat it in an oven at 150°C for 24 hours, separate the solid and liquid after the reaction is completed, and wash to obtain the precursor;

[0047] (3) Mix the precursor obtained in step (2) with sodium sulfide, wherein the molar ratio of sodium sulfide to ammonium molybdate is 1:4, transfer it to a closed reaction kettle again, and heat it in an oven at 100°C for 10 hours to react After completion, solid-liquid separation and cleaning;

[0048] (4) The material obtained in step (3) was heat-treated at 750° C. for 3 hours to obtain a molybdenum sulfide fl...

Embodiment 2

[0052] (1) Splash a layer of silver on the surface of the dust-free cloth, the mass ratio of silver to dust-free cloth is 1:8;

[0053] (2) The material obtained in step (1) is mixed with ammonium thiomolybdate, ammonium fluoride and urea, wherein the mass ratio of ammonium thiomolybdate and dust-free cloth is 4:1, ammonium thiomolybdate, fluorine The molar ratio of ammonium chloride and urea is 1:3:5, the mixture is transferred to a closed reaction kettle, and heated in an oven at 200°C for 5 hours. After the reaction is completed, the solid-liquid separation is performed, and the precursor is obtained by cleaning;

[0054] (3) The precursor that step (2) is obtained is mixed with sodium thiosulfate, wherein the mol ratio of sodium thiosulfate to ammonium thiomolybdate is 1:2, and is transferred to the airtight reaction kettle again, in the oven at 120 Water heating at ℃ for 8 hours, solid-liquid separation after the reaction is completed, and cleaning;

[0055] (4) The mate...

Embodiment 3

[0059] (1) Splash a layer of copper on the surface of the cotton cloth, and the mass ratio of copper to dust-free cloth is 1:10;

[0060] (2) The material obtained in step (1) is mixed with sodium molybdate, ammonium fluoride and urea, wherein the mass ratio of sodium molybdate and dust-free cloth is 3:1, the molar ratio of sodium molybdate, ammonium fluoride and urea The ratio is 1:10:10, transfer the mixture to a closed reaction kettle, and heat it in an oven at 120°C for 20 hours. After the reaction is completed, the solid and liquid are separated and cleaned to obtain the precursor;

[0061] (3) Mix the precursor obtained in step (2) with sodium sulfide, wherein the molar ratio of sodium sulfide to sodium molybdate is 1:3, transfer it to a closed reaction kettle again, and heat it in an oven at 90°C for 12h, and react After completion, solid-liquid separation and cleaning;

[0062] (4) heat-treating the material obtained in step (3) at 1000° C. for 1 h to obtain a molybde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com