Polymer porous microsphere, carbon sphere and ultra-black material prepared from the same, and applications

A technology of porous microspheres and polymers, applied in the fields of biochemical equipment and methods, applications, alkali metal compounds, etc., can solve the problems of difficult to achieve large-scale preparation and wide-ranging applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Take 0.3-3.0g polyvinylidene chloride (PVDC) and dissolve it in 10g DMF at 80-100°C. Preheat 40-100mL of 2.0g Span 85 and 1.0g Tween liquid paraffin to 85°C and add it to the above PVDC solution, keep it at a stirring rate of 500-1500rpm for 30 minutes, then apply an ice bath to quickly cool down, and continue stirring After 10-20 minutes, 20-50 mL of isopropanol was added dropwise thereto (within 10 minutes to 1 hour). After continuing to stir for 1 hour, pour the above emulsion into a large amount of ethanol and petroleum ether mixed solution (volume ratio 1:1), filter after stirring and standing still, wash twice with ethanol petroleum ether mixed solution, wash twice with ethanol, and dry naturally to obtain PVDC polymer porous microspheres.

[0105] figure 1 It is the electron micrograph of the PVDC polymer porous microsphere of embodiment 1; figure 1 As shown, the porosity of the microsphere is 48-94%, the particle size is 2-10 microns, the basic unit is PVDC p...

Embodiment 2

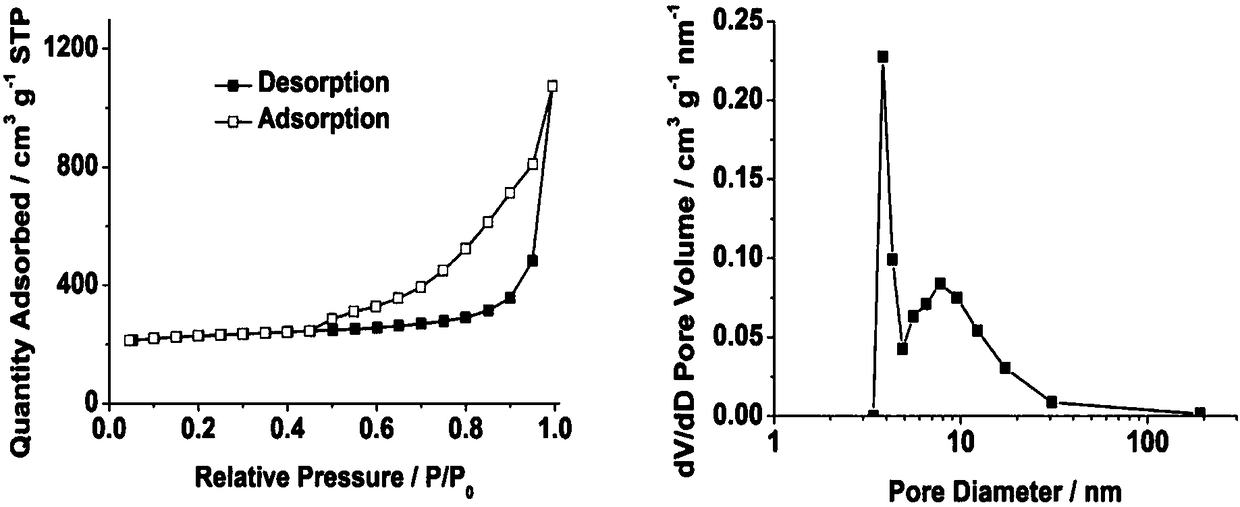

[0107] After the PVDC polymer porous microspheres of Example 1 are poured into a mixed solution of ethanol and petroleum ether, the polymer slurry is obtained by washing and filtering under normal pressure, and added to 50-80mL of KOH in ethylene glycol solution (concentration is 0.2-2mol / L), reflux at 180°C for 4 hours, filter with suction, wash with water and ethanol three times respectively, and dry naturally. The obtained dechlorinated pellets were heated to 1000° C. in a tube furnace and kept for 1 hour (the heating rate was 2° C. / min) to obtain carbon pellets. It looks like figure 2 As shown, it can be seen that compared with the PVDC polymer porous microspheres of Example 1, the morphology of the carbon spheres prepared in Example 2 is well maintained. The nitrogen adsorption curve and pore distribution curve of the obtained carbon spheres are as follows: image 3 As shown, it can be seen that carbon spheres have a relatively rich pore structure. For carbon spheres...

Embodiment 3

[0110] Since the composition of the carbon spheres in Example 2 is extremely high defect graphitic carbon (XRD characterization and Raman characterization as Figure 4 Shown), and the density is low, so it is a good light-absorbing material. Disperse 0.2-0.5g of the carbon spheres obtained in Example 2 in 1-10mL of isopropanol, add 1-5% of PVP as a thickener and binder, and use the method of solution spraying to deposit on the PMMA substrate. When the coating thickness is 80 microns, such as Figure 5 As shown, the carbon spheres can absorb more than 99% of the incident light in the ultraviolet-visible and infrared regions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com