Adhesive self-resistance heating/super-hydrophobic integrated gradient thin film material

A thin-film material, super-hydrophobic technology, applied in ohmic resistance heating, thin-film/sheet-like adhesives, electric heating devices, etc. The effect of low energy consumption electric heating deicing, improving energy utilization efficiency and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

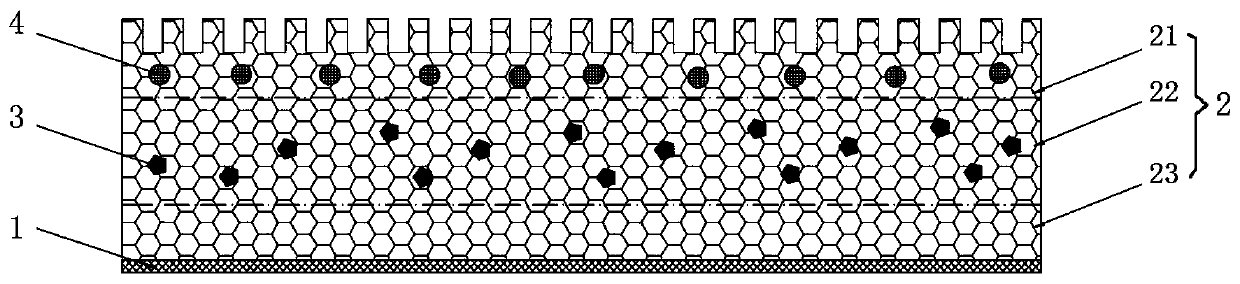

[0031] refer to figure 1 , the stickable self-resistance heating / superhydrophobic integrated gradient film material provided by the present invention is made of adhesive resin, insulating and heat insulating resin, thermally conductive and conductive filler 3 and thermally conductive and insulating filler 4, wherein:

[0032] The adhesive resin and the insulating and heat-insulating resin respectively form an adhesive layer 1 and a matrix 2, and the two are bonded together, the adhesive layer 1 is on the bottom, and the matrix 2 is on the top;

[0033] Thermally conductive and electrically conductive fillers 3 and thermally conductive and insulating fillers 4 are respectively added to the middle layer and the upper layer of the substrate 2, and the substrate 2 is divided into three gradient areas from top to bottom: the insulating and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com