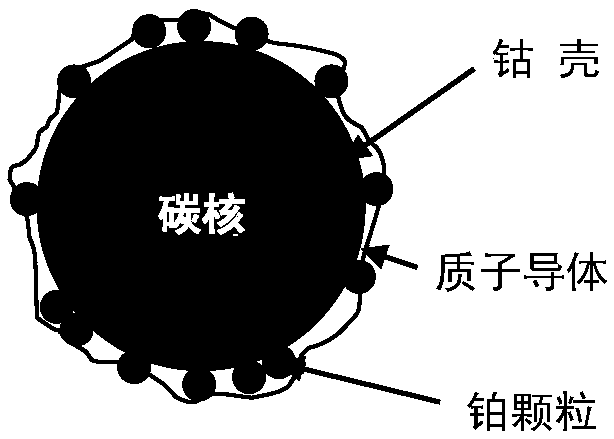

Cobalt-coated carbon-supported platinum catalyst with proton transport function and a preparation method thereof

A platinum catalyst and carbon-coated technology, which is applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve problems affecting the utilization rate of catalysts, optimize electrocatalytic activity, reduce costs, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

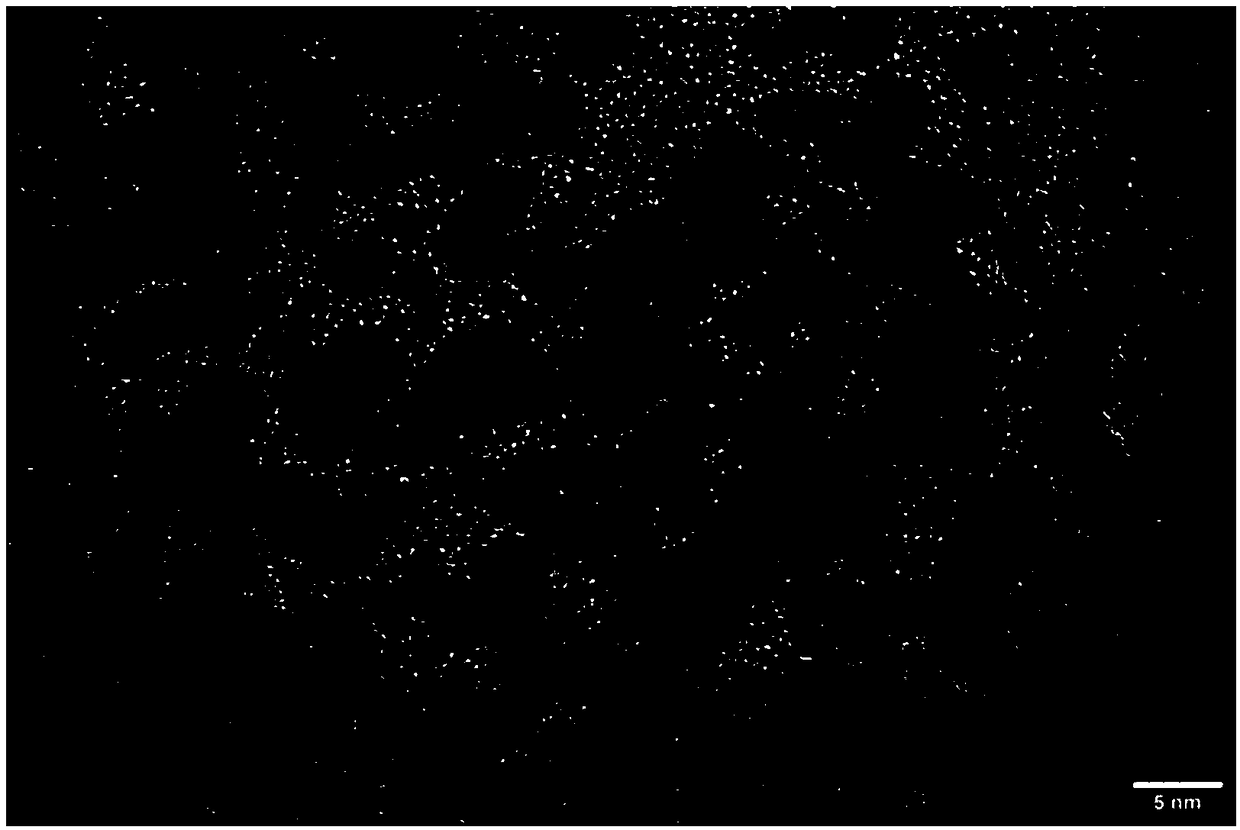

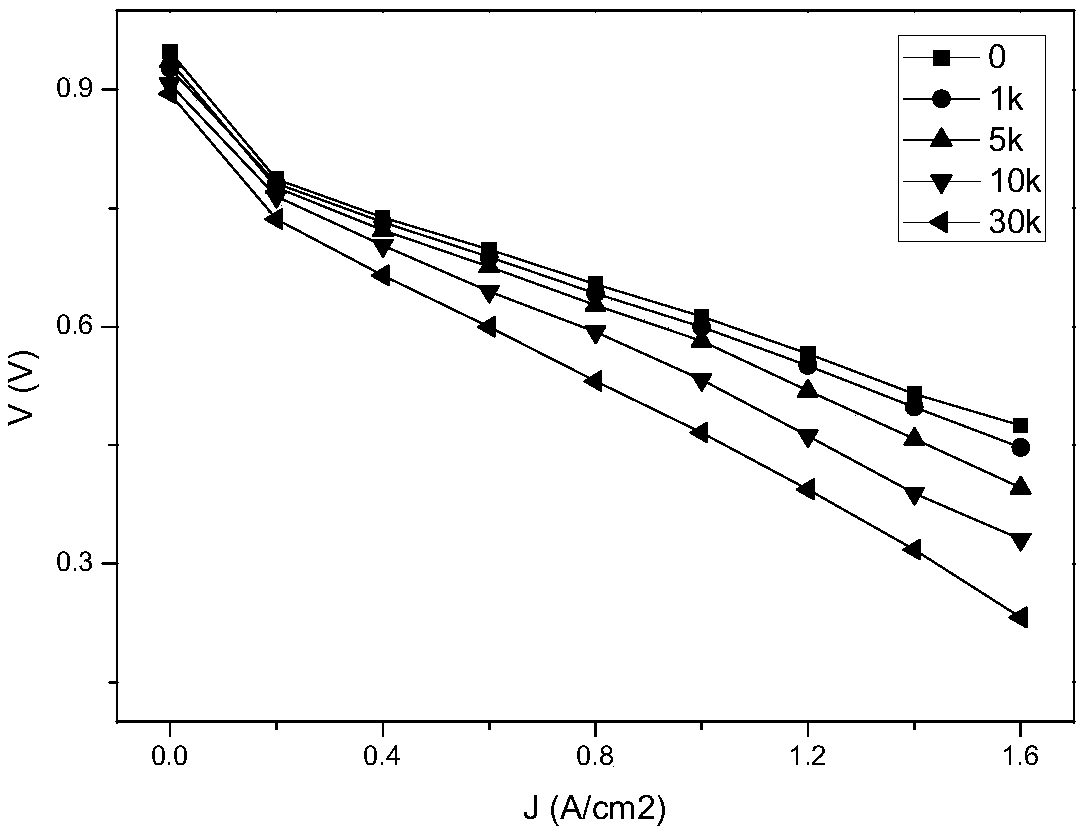

Examples

Embodiment 1

[0038] 1. Dissolve 1g EC-300 carbon black carrier in 10ml of melamine aqueous solution with a concentration of 0.03g / mL, immerse it for 10h, place it in a vacuum drying oven at 80°C for 15h, and place it in N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0039] 2. Adopt electroless plating method to analyze pure CoSO 4 .7H 2 O, CoCl 2 .6H 2 O was used as cobalt source, hydrazine hydrate was used as reducing agent, and PdCl was added. 4 As an activator, increases the wrap rate. In the coating process, KOH is used as the dispersant, and the pH is preferably controlled at 12.5. The ratio of alkali to hydrazine was 6:1, and the reaction temperature was controlled at 89 °C to prepare a core-shell structure of a Co-coated layer C@Co on the surface of the doped carbon black.

[0040] 3. Take 0.18 g of the treated C@Co core-shell structure particles and place them in an autoclave, add perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride (PSVE)...

Embodiment 2

[0057] 1. Dissolve 1g of XC-72 carbon black carrier in 15ml of an aqueous solution of melamine with a concentration of 0.03g / mL, soak it for 10h, place it in a vacuum drying oven at 80°C for 15h, and place it in N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0058] 2. Adopt electroless plating method to analyze pure CoSO 4 .7H 2 O, CoCl 2 .6H 2 O was used as cobalt source, hydrazine hydrate was used as reducing agent, and PdCl was added. 4 As an activator, increases the wrap rate. During the coating process, KOH was used as the dispersant, and the pH was controlled at 12. The ratio of alkali to hydrazine was 5:1, and the reaction temperature was controlled at 90 °C. A Co-coated layer C@Co core-shell structure was prepared on the surface of the doped carbon black.

[0059] 3. Take 0.12 g of the treated C@Co core-shell structure and place it in an autoclave, add an aqueous solution of perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride...

Embodiment 3

[0068] 1. Dissolve 1 g of EC-300 carbon black carrier in 20 mL of an aqueous solution of pyridine with a concentration of 0.05 g / mL, soak for 10 h, place it in a vacuum drying oven at 80 °C for 15 h, and place it in N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0069] 2. Adopt electroless plating method to analyze pure CoSO 4 .7H 2 O, CoCl 2 .6H 2 O was used as cobalt source, hydrazine hydrate was used as reducing agent, and PdCl was added. 4 As an activator, increases the wrap rate. In the coating process, KOH is used as the dispersant, and the pH is preferably controlled at 12.5. The ratio of alkali to hydrazine was 6:1, and the reaction temperature was controlled above 85 °C to prepare a core-shell structure of a Co-coated layer C@Co on the surface of the doped carbon black.

[0070] 3. Take 0.12 g of the treated Co-coated C@Co core-shell structure and place it in an autoclave, add perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com