Preparation method for tin-doped indium sulfide flower-like nano material and application of nano material in photocatalytic reduction

A nanomaterial, indium sulfide technology, applied in physical/chemical process catalysts, nanotechnology for materials and surface science, tin compounds, etc., can solve the problem of small accessible surface area, limited application and promotion, and poor photocatalytic reduction performance. and other problems, to achieve the effect of low equipment requirements, good repeatability, high stability and catalytic reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

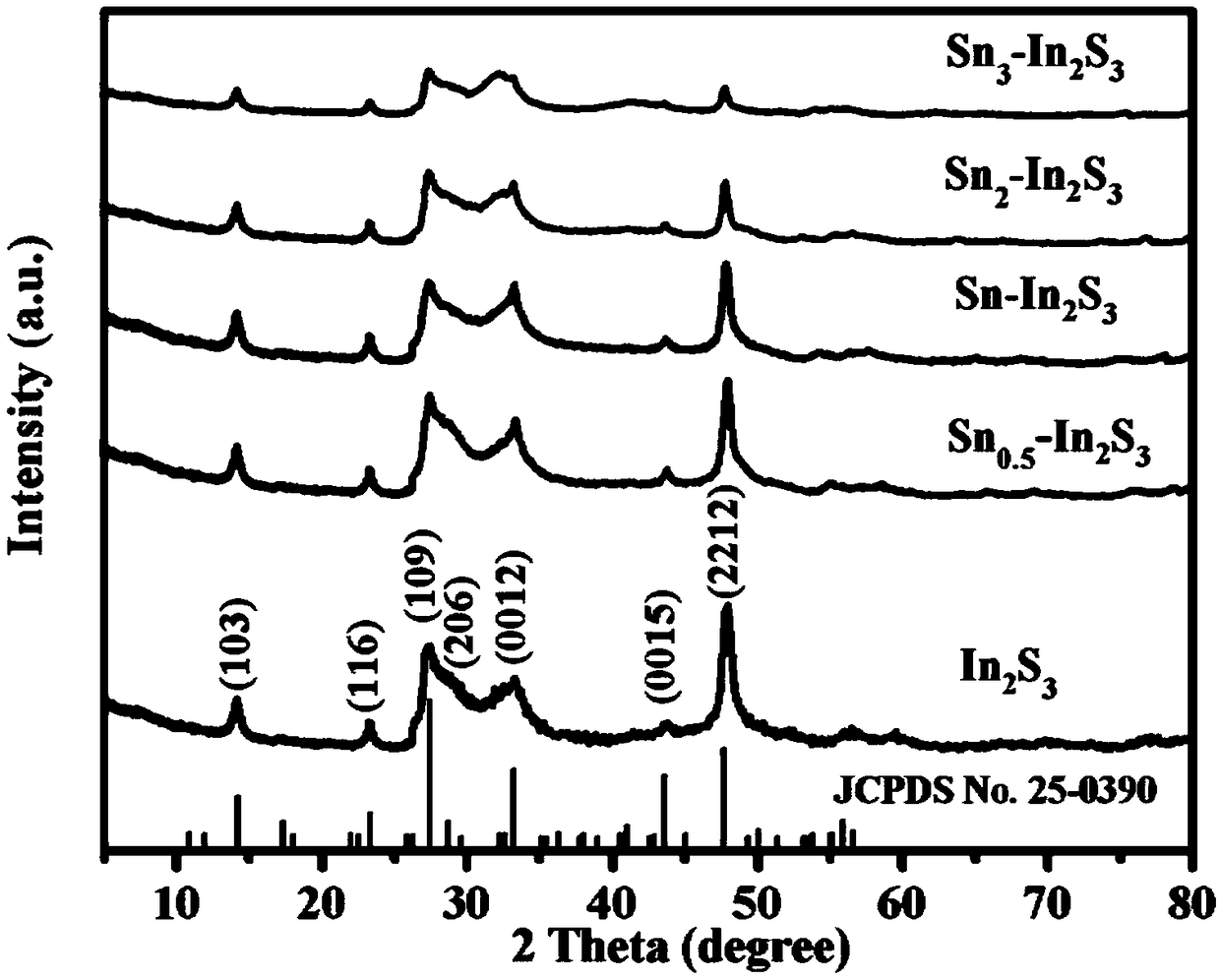

[0026] Preparation of single In by hydrothermal method 2 S 3 . 4.8 mmol InCl 3 4H 2 O and 12 mmol thioacetamide were dissolved in 80 mL of absolute ethanol, and stirred at room temperature until completely dissolved. The solution was transferred to a 100mL polytetrafluoroethylene autoclave, and placed in an oven at 160°C for 12 hours. Cool naturally to room temperature, collect the yellow sediment, centrifuge and wash several times with distilled water and anhydrous ethanol, and then dry under vacuum at 80°C for 12 hours to obtain In 2 S 3 Photocatalyst samples. The X-ray diffraction pattern of the obtained sample is shown in the figure, and the result shows that the obtained product is β-In 2 S 3 , whose diffraction peaks are consistent with JCPDS No. 25-0309 card.

Embodiment 2

[0028] Synthesis of Sn-doped In by hydrothermal method 2 S 3 catalyst of light. 4.8 mmol InCl 3 4H 2 O and 0.5 mmol SnCl 4 ·5H 2 O was dissolved in 80 mL of absolute ethanol, and then 12 mmol of thioacetamide was added, and stirred at room temperature until completely dissolved. The solution was transferred to a 100mL polytetrafluoroethylene autoclave, and placed in an oven at 160°C for 12 hours. Naturally cool to room temperature, collect the yellow sediment, centrifuge and wash several times with distilled water and anhydrous ethanol, and then dry at 80°C under vacuum for 12 hours to obtain Sn 0.5 -In 2 S 3 Photocatalyst samples.

Embodiment 3

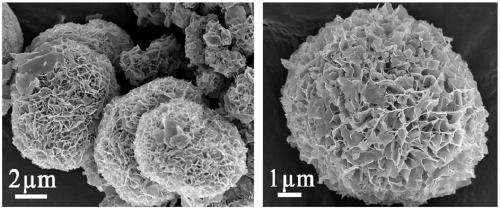

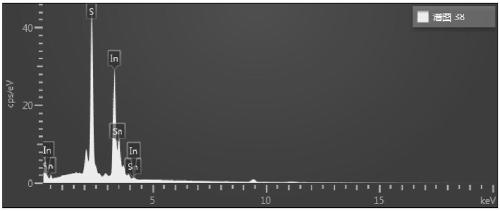

[0030] Synthesis of Sn-doped In by hydrothermal method 2 S 3 catalyst of light. 4.8 mmol InCl 3 4H 2 O and 1 mmol SnCl 4 ·5H 2 O was dissolved in 80 mL of absolute ethanol, and then 12 mmol of thioacetamide was added, and stirred at room temperature until completely dissolved. The solution was transferred to a 100mL polytetrafluoroethylene autoclave, and placed in an oven at 160°C for 12h. Naturally cool to room temperature, collect the yellow sediment, centrifuge and wash several times with distilled water and anhydrous ethanol, and then dry at 80°C under vacuum for 12 hours to obtain Sn-In 2 S 3 Photocatalyst samples. The X-ray diffraction pattern of the obtained sample is shown in the figure, and the result shows that the obtained product is β-In 2 S 3 , and its diffraction peaks are consistent with the JCPDS No. 25-0309 card; the scanning electron microscope image of the obtained sample shows that the product prepared by this process is a nano-curd, and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com