Gamma-tocotrienol-containing nano emulsion and preparation method and use thereof

A technology of tocotrienol and nanoemulsion, which is applied in the direction of medical preparations containing active ingredients, medical preparations with non-active ingredients, emulsion delivery, etc., and can solve the problem of unstable alkaline conditions and γ-tocotrienol Unsuitable, sensitive to oxygen and other problems, to achieve uniform and stable particle size, maintain the basic properties of the drug, and reduce blood vessel irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of γ-tocotrienol nanoemulsion

[0044] (1) Take 11g of soybean oil and medium-chain triglyceride oil (1:1), heat it in a water bath to 60°C, add 0.05g of γ-tocotrienol, 1.2g of egg yolk lecithin and 0.005g of sodium sulfite, stir to dissolve, A homogeneous mixture is formed, which is liquid A.

[0045] (2) Add 2.3 g of isotonicity regulator glycerin and sorbitol (3:1) into disodium hydrogen phosphate alkaline water at 70°C, stir to dissolve, keep warm in a water bath for later use, and fill with nitrogen throughout the process to form liquid B.

[0046] (3) Disperse liquid A before high-speed shearing, slowly add liquid B during shearing, continue shearing for 15 minutes after adding liquid B, and carry out nitrogen protection throughout the process.

[0047] (4) Colostrum is homogenized under high pressure, adjust the pressure level of the secondary homogenization to 80 bar, the pressure of the primary level to 800 bar, and homogenize 8 times.

...

Embodiment 2

[0049] Example 2 Preparation of γ-tocotrienol nanoemulsion

[0050] (1) Take 120g of soybean oil and medium-chain triglyceride oil (1:1), heat it in a water bath to 80°C, add 10g of γ-tocotrienol, 15g of soybean lecithin and 0.1g of sodium sulfite, stir to dissolve, and form a uniform The mixture is liquid A.

[0051] (2) Take 25 g of isotonic regulator glycerin and add it to disodium hydrogen phosphate alkaline water at 70°C, stir to dissolve, keep warm in a water bath for later use, and fill the whole process with nitrogen gas to become liquid B.

[0052] (3) Disperse liquid A before high-speed shearing, slowly add liquid B during shearing, continue shearing for 14 minutes after adding liquid B, and carry out nitrogen protection throughout the process.

[0053] (4) Colostrum is homogenized under high pressure, adjust the pressure level of the secondary homogenization to 80 bar, the pressure of the primary level to 800 bar, and homogenize 8 times.

[0054] (5) Adjust the pH...

Embodiment 3

[0055] Example 3 Preparation of γ-tocotrienol nanoemulsion

[0056] (1) Take 8g of soybean oil, heat it in a water bath to 60°C, add 0.1g of γ-tocotrienol, 1.1g of soybean lecithin and 0.005g of cysteine, stir and dissolve, and form a uniform mixture, which is liquid A.

[0057] (2) Add 2.1 g of isotonicity regulator glycerin and sorbitol (3:1) into disodium hydrogen phosphate alkaline water at 70°C, stir to dissolve, keep warm in a water bath for later use, and fill with nitrogen throughout the process to form liquid B.

[0058] (3) Disperse liquid A before high-speed shearing, slowly add liquid B during shearing, continue shearing for 12 minutes after adding liquid B, and carry out nitrogen protection throughout the process.

[0059] (4) Colostrum is homogenized under high pressure, adjust the pressure level of the secondary homogenization to 80 bar, and the pressure of the primary level to 800 bar, and homogenize 6 times.

[0060] (5) Adjust the pH to 7.0 with acidic solut...

PUM

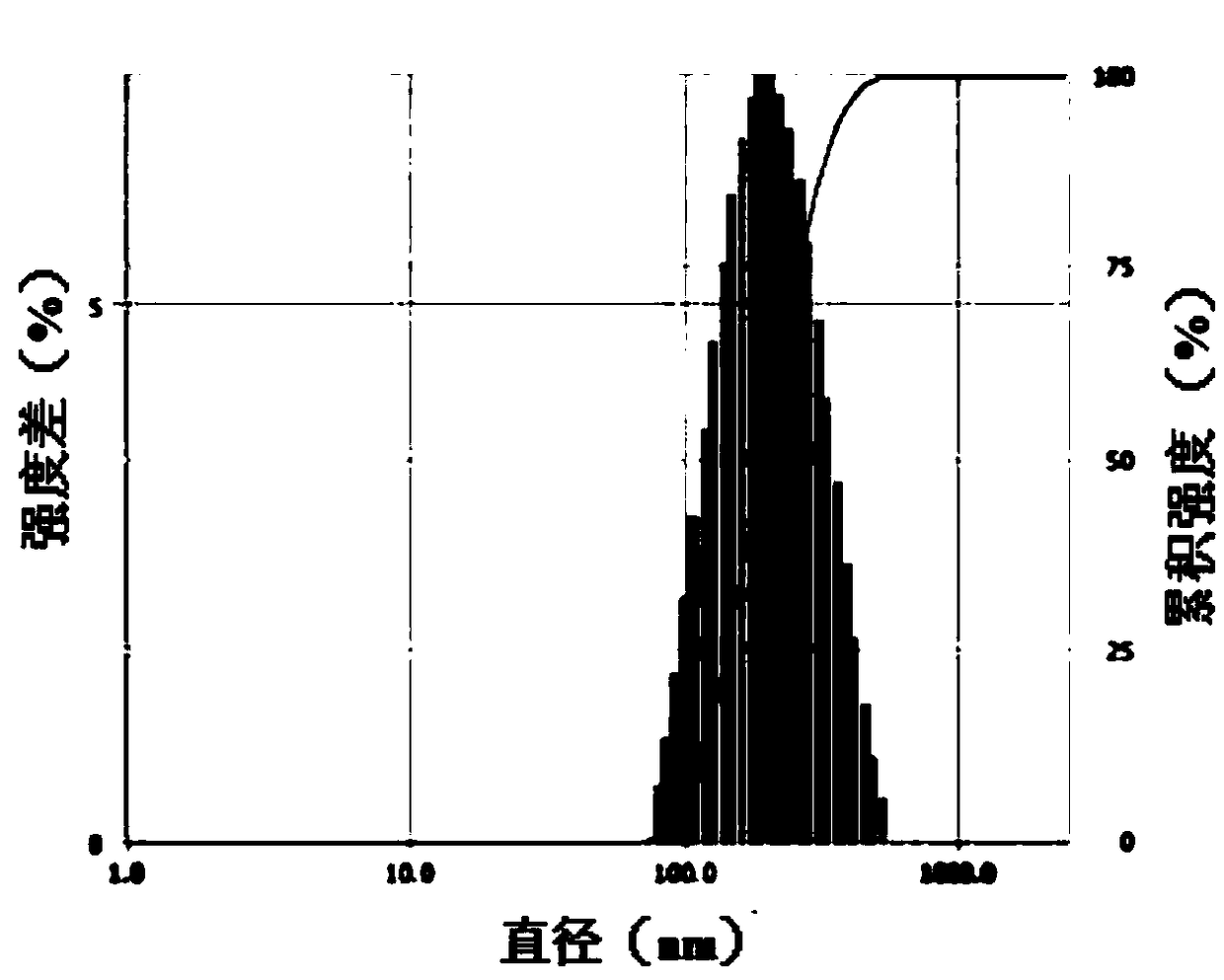

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com