Latent curing type single-component polyurethane adhesive and preparation method thereof

A polyurethane adhesive and latent curing agent technology, applied in the field of materials, can solve the problems of affecting the performance of the adhesive, restricting the application and development of the adhesive, and reducing the strength, so as to improve the mechanical properties and bonding properties, improve the surface drying and curing speed, and prevent air bubbles The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: preparation of one-component polyurethane adhesive

[0024] (1) Distill polyether polyol 220 under reduced pressure at 120°C and -0.1MPa for 2 hours, take 100 parts of distilled polyether polyol 220 and add it to a four-port tank with vent pipe, condenser pipe and stirring paddle Go to the flask, pass nitrogen before adding, and gradually increase to 70°C; then slowly add 30 parts of diphenylmethane diisocyanate (MDI) dropwise, add dropwise while stirring, and use di-n-butylene every 30 minutes after the reaction starts. The content of -NCO group in the reaction system was titrated by the amine titration method. When the content of -NCO group reached the theoretical value, the reaction was stopped. This process required 2 hours of reaction to obtain a polyurethane prepolymer.

[0025] (2) the polyurethane prepolymer in the step (1) is cooled to 60° C., and 5.6 parts of 1,4 butanediol are slowly added dropwise to a four-necked flask containing the polyureth...

Embodiment 2

[0027] Embodiment 2: preparation of one-component polyurethane adhesive

[0028] (1) First, polyether polyol 220 was distilled under reduced pressure at 120°C and -0.1MPa for 2 hours, and 100 parts of polyether polyol 220 after distillation was added to a four-wheel tank with vent pipe, condenser pipe and stirring paddle. Put the nitrogen in the mouth of the flask, pass the nitrogen gas before adding, and gradually raise it to 70°C; then slowly add 30 parts of diphenylmethane diisocyanate (MDI) dropwise, and add dropwise while stirring. After the reaction starts, use two normal The content of -NCO group in the reaction system was titrated by butylamine titration. When the content of -NCO group reaches the theoretical value, the reaction is stopped, and this process needs to be reacted for 2 hours to obtain a polyurethane prepolymer.

[0029] (2) the polyurethane prepolymer in the step (1) is cooled to 60° C., and 5.6 parts of 1,4 butanediol are slowly added dropwise to a four...

Embodiment 3

[0031] Embodiment 3: preparation of one-component polyurethane adhesive

[0032] (1) First, polyether polyol 220 was distilled under reduced pressure at 120°C and -0.1MPa for 2 hours, and 100 parts of polyether polyol 220 after distillation was added to a four-wheel tank with vent pipe, condenser pipe and stirring paddle. Put the nitrogen in the mouth of the flask, pass the nitrogen gas before adding, and gradually raise it to 70°C; then slowly add 30 parts of diphenylmethane diisocyanate (MDI) dropwise, and add dropwise while stirring. After the reaction starts, use two normal The content of -NCO group in the reaction system was titrated by butylamine titration. When the content of -NCO group reaches the theoretical value, the reaction is stopped, and this process needs to be reacted for 2 hours to obtain a polyurethane prepolymer.

[0033] (2) the polyurethane prepolymer in the step (1) is cooled to 60° C., and 5.6 parts of 1,4 butanediol are slowly added dropwise to a four...

PUM

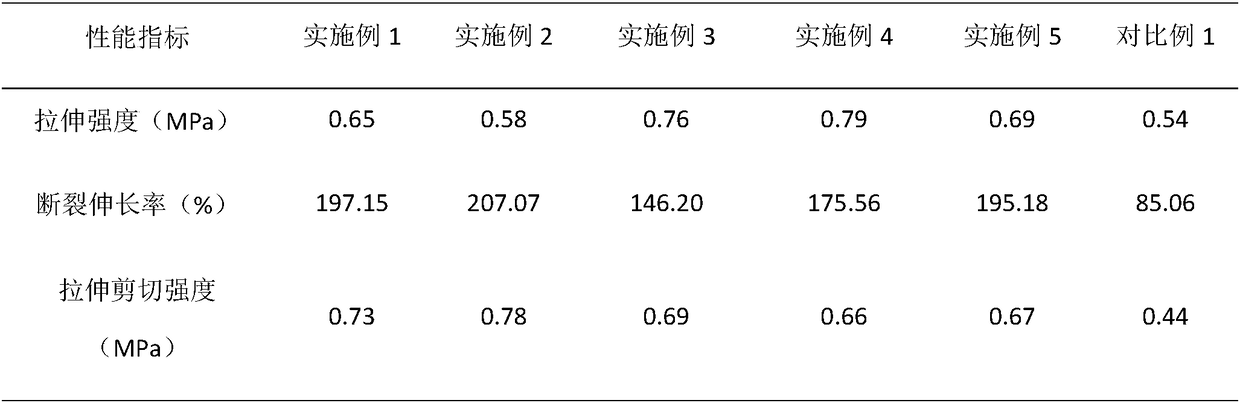

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com