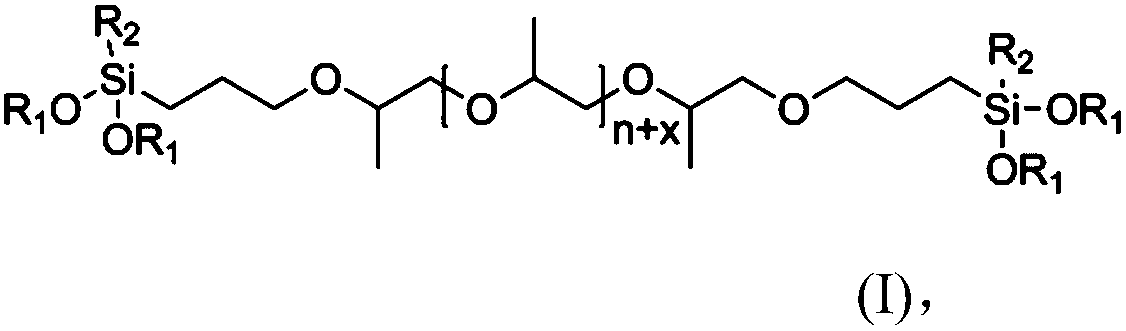

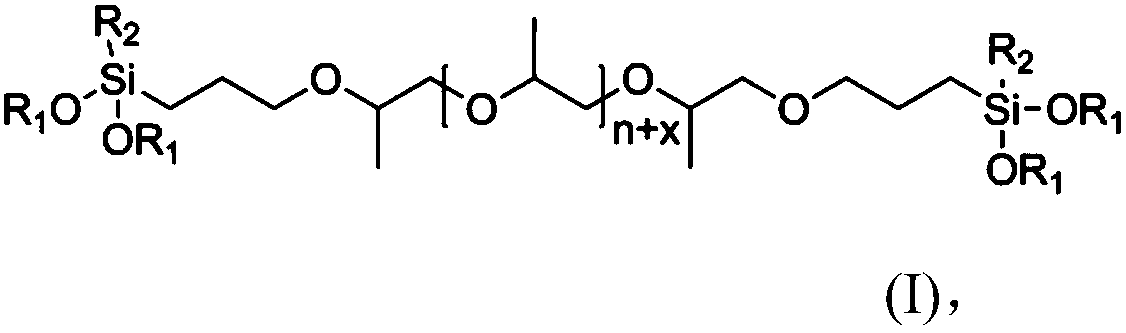

Preparation method of silane-modified polyether sealant

A technology of silane-modified polyether and sealant, applied in the field of sealant, can solve the problems of long-term storage of unfavorable products, deactivation of raw materials, limitation of raw materials, etc., so as to shorten the total heating and total cooling time, reduce the heating and cooling time, and reduce the The effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a preparation method of silane-modified polyether sealant, comprising the following steps:

[0039] Step 1), drying titanium dioxide, nano-calcium carbonate, polyamide wax and 3A molecular sieve respectively, the process conditions include: drying temperature 50°C, drying time 48h;

[0040] Step 2), mixing 15 parts of titanium dioxide, 210 parts of nano-calcium carbonate, 3 parts of polyamide wax and 10 parts of 3A molecular sieve after step 1), and then adding 100 parts of trimethoxysilane modified polyether, 80 parts 1 part of diisononyl phthalate, 1 part of UV absorber is Tinuvin 326, 1 part of light stabilizer is Tinuvin 770, 1 part of antioxidant is Irganox 245, mix evenly, vacuum dehydrate, process conditions include: mixing temperature 50 ℃, vacuum dehydration for 0.5h, vacuum degree is -0.1MPa;

[0041] Step 3), release the vacuum, add 20 parts of neutral alumina (accounting for 4.6% of the total mass of each raw material) to obtain a m...

Embodiment 2

[0044] This embodiment provides a preparation method of silane-modified polyether sealant, comprising the following steps:

[0045]Step 1), drying titanium dioxide, nano-calcium carbonate, polyamide wax and 3A molecular sieve respectively, the process conditions include: drying temperature 55°C, drying time 40h;

[0046] Step 2), mixing 15 parts of carbon black, 210 parts of nano-calcium carbonate, 3 parts of fumed silica and 10 parts of 3A molecular sieve after step 1), and then adding 100 parts of trimethoxysilane modified polyether in sequence , 80 parts of diisononyl phthalate, 1 part of UV absorber is Tinuvin 329, 1 part of light stabilizer is Tinuvin 770, 1 part of antioxidant is Irganox 1010, mix well, vacuum dehydrate, process conditions include: mixing The temperature is 55°C, the vacuum dehydration is 0.6h, and the vacuum degree is -0.09MPa;

[0047] Step 3), release the vacuum, add 25 parts of neutral alumina (accounting for 5.8% of the total mass of each raw mater...

Embodiment 3

[0050] This embodiment provides a preparation method of silane-modified polyether sealant, comprising the following steps:

[0051] Step 1), drying titanium dioxide, nano-calcium carbonate, polyamide wax and 3A molecular sieve respectively, the process conditions include: drying temperature 60°C, drying time 48h;

[0052] Step 2), mixing 15 parts of titanium dioxide, 210 parts of nano-calcium carbonate, 3 parts of polyamide wax and 10 parts of 3A molecular sieve after step 1), and then adding 100 parts of trimethoxysilane modified polyether, 80 parts 1 part of diisononyl phthalate, 1 part of UV absorber is Tinuvin 326, 1 part of light stabilizer is Tinuvin 770, 1 part of antioxidant is Irganox 245, mix well, vacuum dehydrate, process conditions include: mixing temperature 60 ℃, vacuum dehydration for 0.3h, vacuum degree is -0.1MPa;

[0053] Step 3), release the vacuum, add 15 parts of neutral alumina (accounting for 3.4% of the total mass of each raw material) to obtain a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com