Arrow anchor rod of multi-section clamping grouting anchoring and using method thereof

A multi-stage grouting technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of uneven deformation of surrounding rock mass, reduction of shear force, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

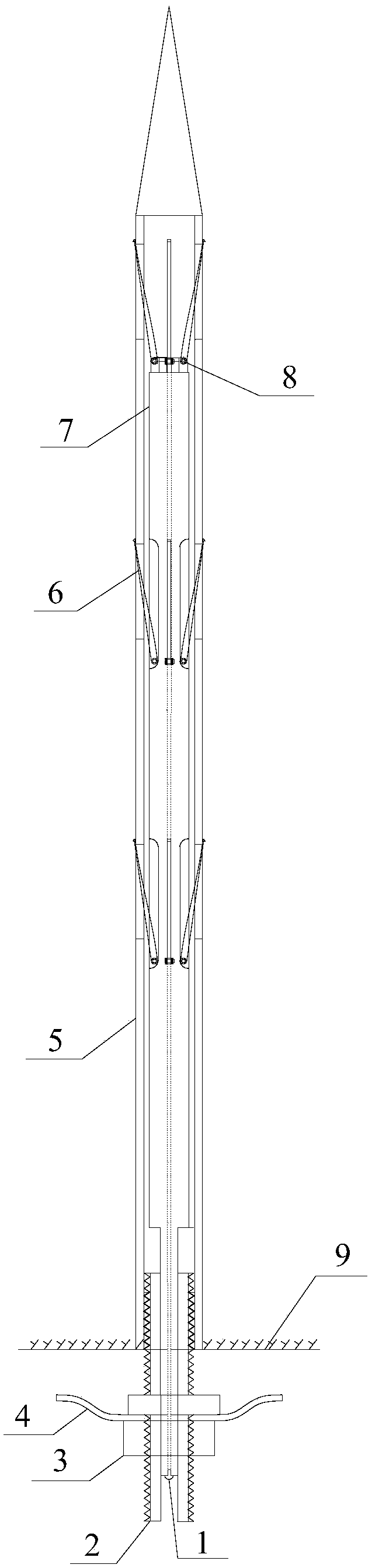

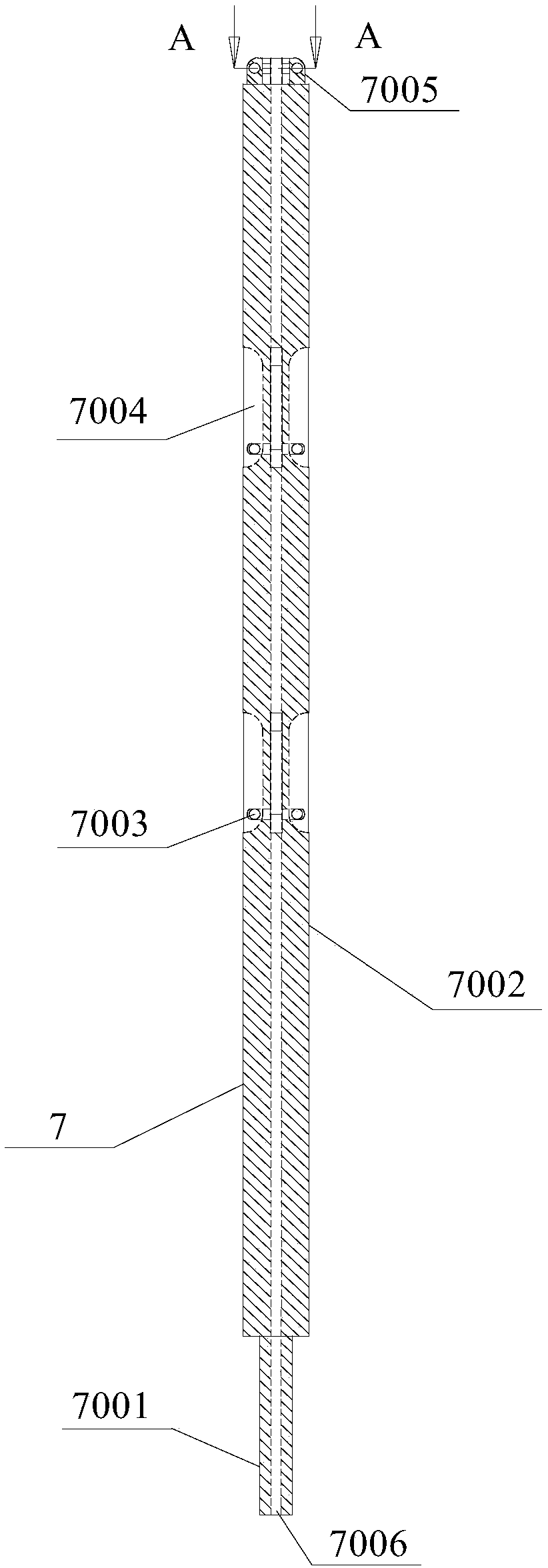

[0046] Such as figure 1 As shown, the present embodiment provides a multi-stage clamping and grouting anchor bolt, including a sleeve 5, a grouting rod device and a sealing device, the grouting rod device is arranged in the sleeve 5, and the grouting rod body The device includes a grouting rod body 7 and multiple groups of anchor heads 6. Each group of anchor heads 6 forms a clamping anchor structure and is hinged on the outer wall of the grouting rod body 7 with screws 8. The sleeve 5 is provided with anchor heads 6 one-to-one. And it is suitable for the slot hole through which the anchor head 6 passes. The solid sealing device includes a double-ended stud 2, a nut 3 and a tray 4. One end of the double-ended stud 2 is fastened between the cylinder body 5 and the grouting rod body 7 to form a tight The size fits, and the screw thread at the other end provides nut 3 to tighten and fix pallet 4.

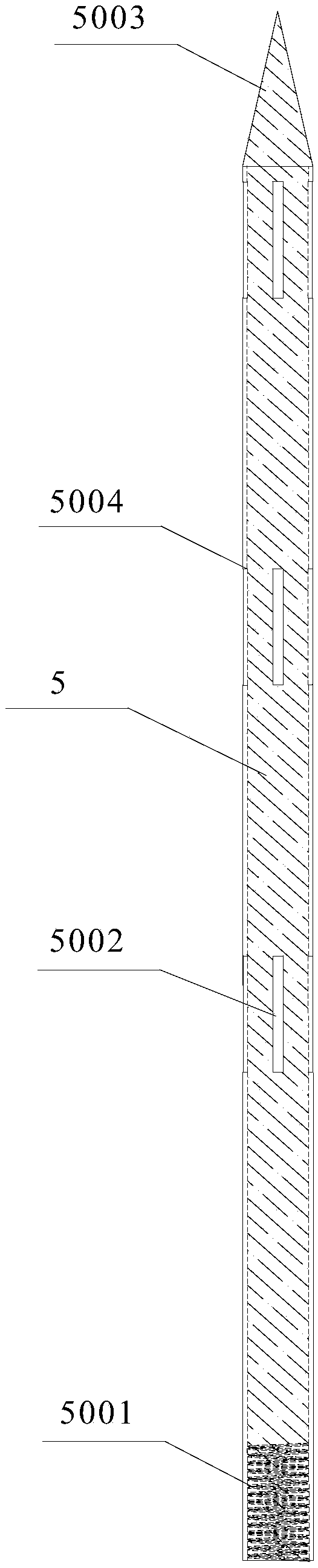

[0047] Such as figure 2 As shown, the sleeve 5 includes an arrow structure 5003...

Embodiment 2

[0053] This embodiment provides a method for using a multi-stage clamping and grouting anchor bolt, including the following steps:

[0054] S1. Install the anchor head 6 on the grouting rod body 7, install the anchor head 6 on the base hole 7003 with the screw 8, and fix the front and rear ends of the screw 8 by soldering, and complete the assembly of all the anchor heads 6 in turn;

[0055] S2. Push one end of the anchor end of the grouting rod body 7 from the open end of the cylinder 5004. When the anchor head 6 reaches the slot 5002, it will pop out and get stuck. At this time, press it in by hand and continue to push it until it is anchored. The anchor head 6 on the end reaches the slotted hole 5002 at the tail end of the cylinder body 5004 and pops up;

[0056] S3, the device formed in the step S2 is packed into the drilled hole of the rock wall 9, and then the sleeve 5 is hammered by means of a tool (hammer or jack) so that the arrowhead structure 5003 is drilled into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com