A stainless steel fluoropolymer synergistic coating treatment process

A fluoropolymer and coating treatment technology, which is applied in metal material coating process, coating, pretreatment surface, etc., can solve the problem that the strength and corrosion resistance of stainless steel materials cannot be greatly improved, and the bonding force between coating and stainless steel surface is very poor. Poor, poor bonding strength with the stainless steel surface, etc., to achieve the effect of not being easily oxidized and polluted, good appearance quality and consistency, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

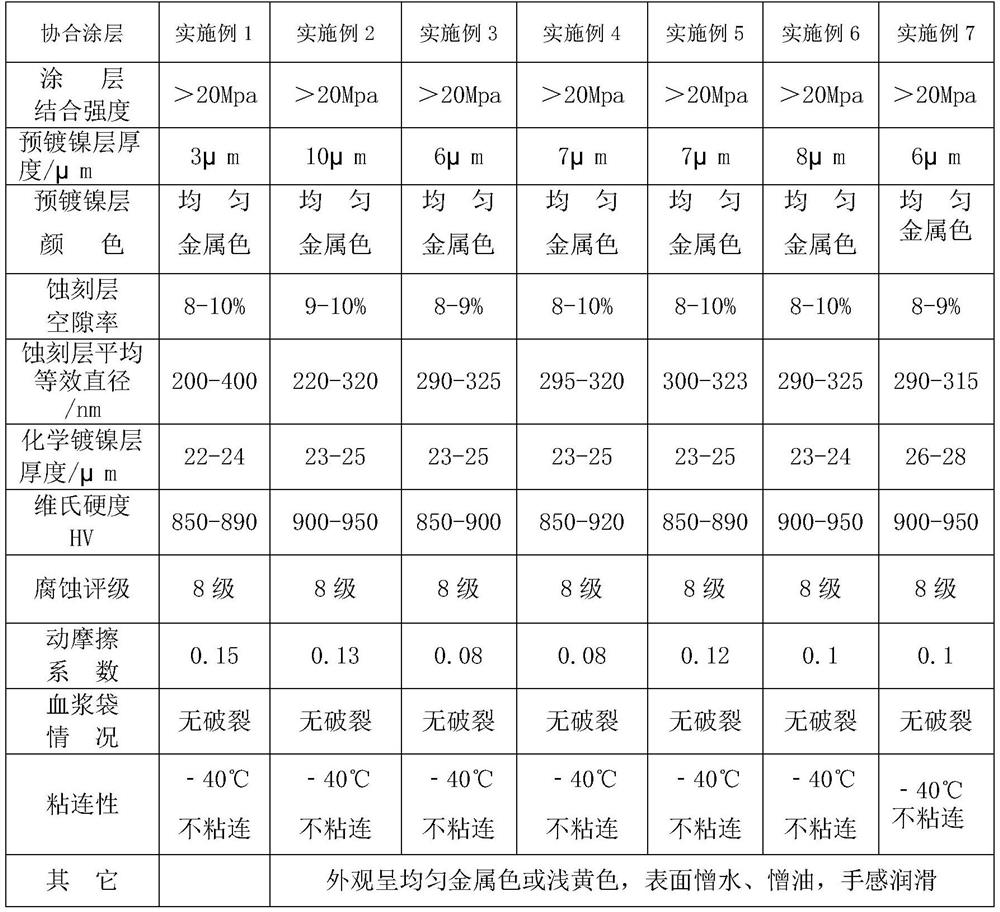

Examples

Embodiment 1

[0023] Select a 304 (06Cr19Ni10) stainless steel test plate with a specification of 50*50*2mm as a sample, polish it to a surface roughness of Ra1.6, and then prepare a stainless steel symbiosis coating according to the following steps:

[0024] Step 1, alkaline degreasing treatment: put the stainless steel test plate in the alkaline degreasing solution, heat up to 60°C and keep the temperature for 20 minutes; among them, the alkaline degreasing solution mainly consists of sodium hydroxide 30g / l, sodium phosphate 10g / l and linear alkylbenzene sulfonate 1g / l;

[0025] Step 2, electrolytic degreasing and degreasing treatment: place the stainless steel test plate after the aforementioned degreasing treatment in 1% degreasing agent (produced by Chongqing Wujiu Surface Technology Engineering Co., Ltd., model HLP30-1 modified) for electrolytic degreasing; wherein, The process conditions of electrolytic degreasing are cathodic degreasing, the temperature is 60°C, and the current den...

Embodiment 2

[0032] Select 316L (00Cr17Ni14Mo2) stainless steel plate as a sample, polish it to a surface roughness of Ra1.6, and then prepare a stainless steel synergy coating according to the following steps:

[0033] Step 1, alkaline degreasing treatment: place the stainless steel sample in the alkaline degreasing solution, heat up to 70°C and keep the temperature for 25 minutes; among them, the alkaline degreasing solution mainly consists of sodium hydroxide 100g / l, sodium phosphate 35g / l and linear alkylbenzene sulfonate sodium 5g / l composition;

[0034] Step 2, electrolytic degreasing and degreasing treatment: place the stainless steel sample after the aforementioned degreasing treatment in 5% degreasing agent (produced by Chongqing Wujiu Surface Technology Engineering Co., Ltd., model HLP30-1 modified) for electrolytic degreasing; wherein, The process conditions of electrolytic degreasing are cathodic degreasing, the temperature is 80°C, and the current density is 10A / dm 2 , the t...

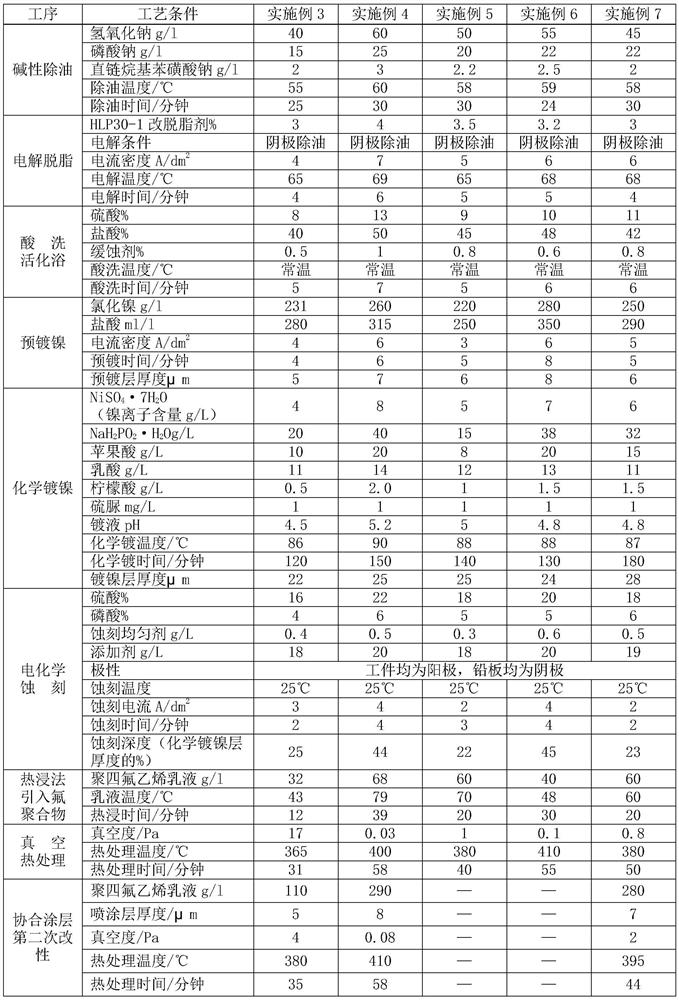

Embodiment 3

[0041] Embodiment 3, embodiment 4: with reference to the step of embodiment 2, prepare stainless steel fluoropolymer synergy coating according to the process parameter in table 1; Wherein, the etching leveling agent of embodiment 3 is emulsifier OP-10 and dodecane The compound solution of sodium phenylsulfonate in mass ratio=2:1, and the additive is the compound solution of sodium succinate and glycine in mass ratio=1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com