Method for recycling mine acid wastewater

A mine acid wastewater and acid wastewater technology, which is applied in the field of metallurgy, can solve the problems of small application range of polyferric sulfate products, long copper precipitation time, secondary pollution, etc., and achieve sustainable and healthy development, maximum utilization of resources, and equipment The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

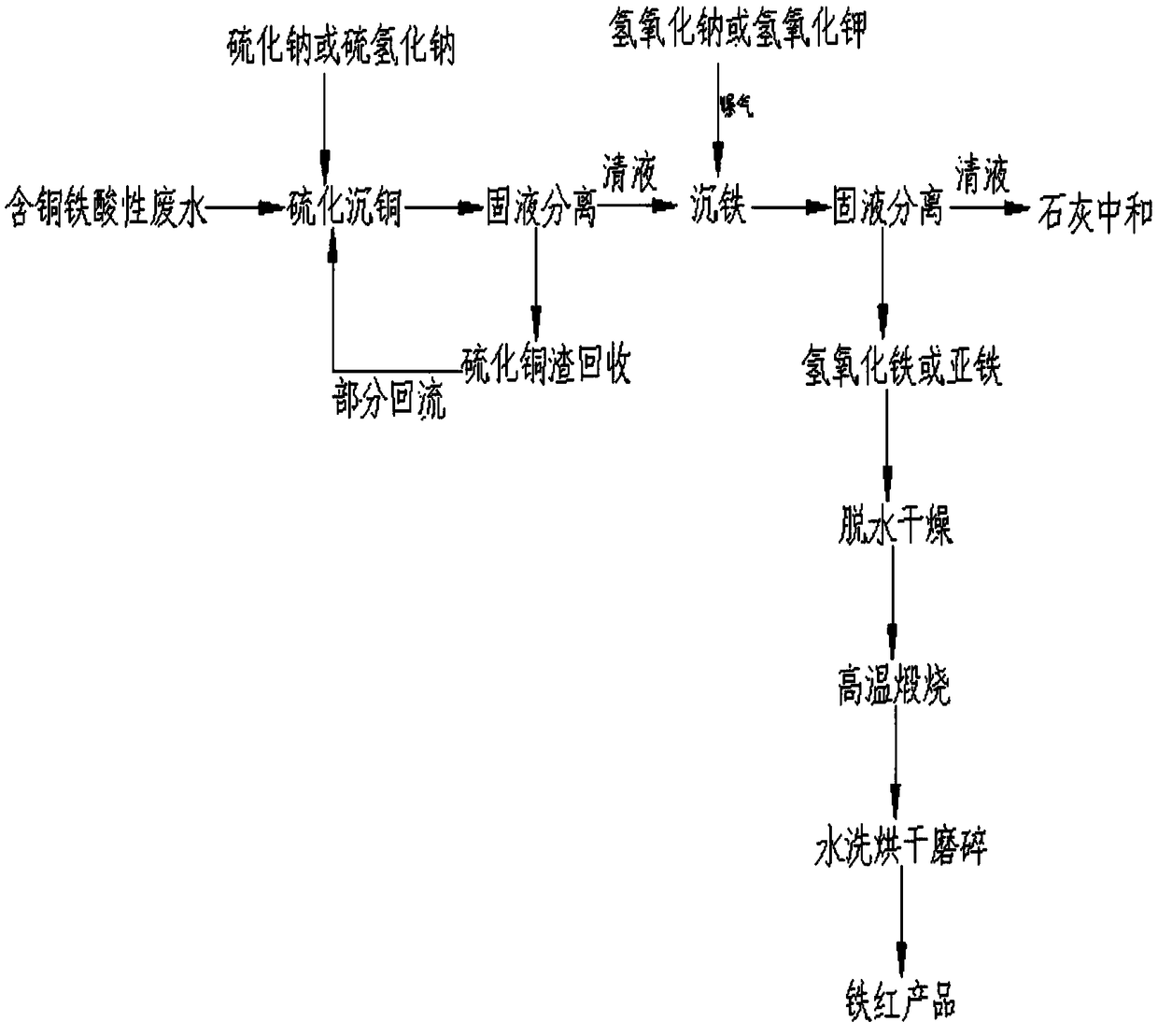

Method used

Image

Examples

Embodiment 1

[0031] A gold-copper mine in Fujian adopts bio-pile leaching copper process. After the copper product is extracted and recovered, the raffinate pH is 1.2-1.8, the copper content is 0.1g / L, the arsenic is 0.08g / L, the zinc is 0.27g / L, and the aluminum is 1.5g / L, ferric iron 8g / L, ferrous iron 2g / L. Add 0.22-0.31 g of sodium sulfide or sodium hydrosulfide to the above-mentioned raffinate 1000 mL to recover copper. The specific recovery process for the added sodium sulfide or sodium hydrosulfide is to add sodium sulfide or sodium hydrosulfide from the water inlet. The whole process The reaction residence time is controlled at 0.5~1.0h, and at the same time, iron or ferrous waste liquid is obtained; sodium hydroxide 20~24g / L is added to the above-mentioned treated liquid, the pH is controlled at 3~3.6, the aeration reaction is 1.0~1.5h, and the aeration The gas volume is 50-100m3 / L, and the aeration temperature is normal temperature to obtain hydroxide; add 5g of lime to the abov...

Embodiment 2

[0033] After extraction and recovery of copper products from a large-scale copper mine in Jiangxi, the raffinate has a pH of 1.8-2.3, copper content of 0.8g / L, arsenic of 0.12g / L, lead of 0.1g / L, zinc of 0.65g / L, and ferric iron of 4g / L, ferrous iron 8g / L. Add 1.75-2.5 g of sodium sulfide or sodium hydrosulfide to the above-mentioned raffinate 1000 mL to recover copper. The added sodium sulfide or sodium hydrosulfide, the specific recovery process is that sodium sulfide or sodium hydrosulfide is added from the water inlet, and after the reaction Directly filter, the reaction residence time of the whole process is controlled at 0.5~1.0h, and at the same time, ferrous or ferrous waste liquid is obtained; add sodium hydroxide 24~28 / L to the above-mentioned treated liquid, control pH3~4, aeration reaction 1.0 ~1.5h, the aeration rate is 60~100m3 / L, the aeration temperature is normal temperature, and the hydroxide is obtained; add lime 2.5g to the above iron-containing waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com