A kind of 2,5-dihydroxyterephthaloyl chloride and preparation method thereof

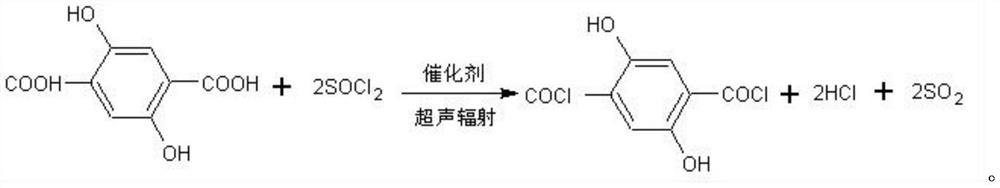

A technology of hydroxyterephthaloyl chloride and hydroxyterephthalic acid, which is applied in the field of 2,5-dihydroxyterephthaloyl chloride and its preparation, and can solve the problems of product mechanical performance degradation, embrittlement, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

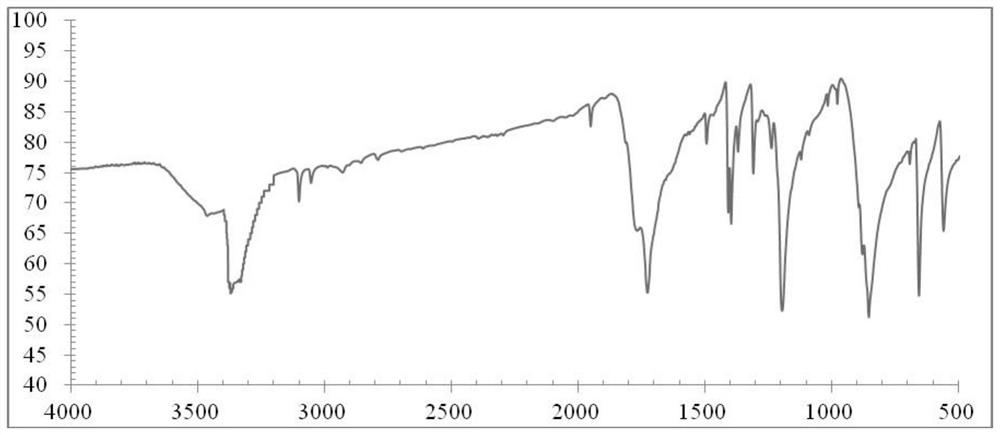

[0035] A kind of preparation method of high-purity 2,5-dihydroxy terephthaloyl chloride of the present invention, comprises the steps:

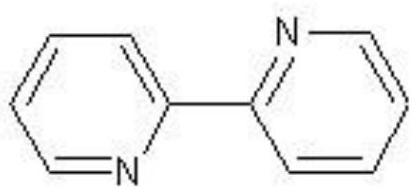

[0036](1) Add 50g of 2,5-dihydroxyterephthalic acid, 61.1g of thionyl chloride and 0.4g of 2,2'-bipyridine into a round-bottomed flask with a reflux condenser, and put it into an ultrasonic instrument, Ultrasonic power 250W, ultrasonic reflux reaction at 80°C for 2h, the hydrogen chloride and sulfur dioxide generated by the reaction were passed into the potassium hydroxide solution with a mass concentration of 20% in time, and then the reaction was ended after no tail gas appeared, and the thionyl chloride and sulfur dioxide were distilled out under reduced pressure. Catalyst 2,2'-bipyridine to obtain 60.6 g of crude 2,5-dihydroxyterephthaloyl chloride, with an isolated yield of 90%;

[0037] (2) Add 0.31g FeCl to the crude 2,5-dihydroxyterephthaloyl chloride obtained after step (1) 3 Heated to 120°C, kept at constant temperature for 1 hour,...

Embodiment 2

[0042] A kind of preparation method of high-purity 2,5-dihydroxy terephthaloyl chloride of the present invention, comprises the steps:

[0043] (1) Add 50g of 2,5-dihydroxyterephthalic acid, 61.1g of thionyl chloride and 0.4g of 2,2'-bipyridine into a round-bottomed flask with a reflux condenser, and put it into an ultrasonic instrument, Ultrasonic power 250W, ultrasonic reflux reaction at 70°C for 2.5h, the hydrogen chloride and sulfur dioxide generated by the reaction were passed into the potassium hydroxide solution with a mass concentration of 20% in time, and then the reaction was ended after no tail gas appeared, and the thionyl chloride was distilled out under reduced pressure and catalyst 2,2'-bipyridine to obtain 58 g of crude 2,5-dihydroxyterephthaloyl chloride, with an isolation yield of 86%;

[0044] (2) Add 0.3g FeCl to the crude 2,5-dihydroxyterephthaloyl chloride obtained after step (1) 3 Heated to 120°C, kept at constant temperature for 1 hour, and vacuum dist...

Embodiment 3

[0048] A kind of preparation method of high-purity 2,5-dihydroxy terephthaloyl chloride of the present invention, comprises the steps:

[0049] (1) Add 50g of 2,5-dihydroxyterephthalic acid, 61.1g of thionyl chloride and 0.4g of 2,2'-bipyridine into a round-bottomed flask with a reflux condenser, and put it into an ultrasonic instrument, Ultrasonic power 250W, ultrasonic reflux reaction at 75°C for 3h, the hydrogen chloride and sulfur dioxide generated by the reaction were passed into the potassium hydroxide solution with a mass concentration of 20% in time, and then the reaction was ended after no tail gas was observed, and the thionyl chloride and sulfur dioxide were distilled out under reduced pressure. Catalyst 2,2'-bipyridine to obtain 60 g of crude 2,5-dihydroxyterephthaloyl chloride with an isolated yield of 89%;

[0050] (2) Add 0.3g FeCl to the crude 2,5-dihydroxyterephthaloyl chloride obtained after step (1) 3 Heated to 120°C, kept at constant temperature for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com