A kind of preparation method of silver oxide supported porous membrane

A technology of silver oxide and porous membrane, which is applied in chemical instruments and methods, botanical equipment and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult separation and recovery of photocatalysts, small specific surface area, adsorption Poor performance and other problems, to achieve the effect of short reaction time, high activity, and efficient decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

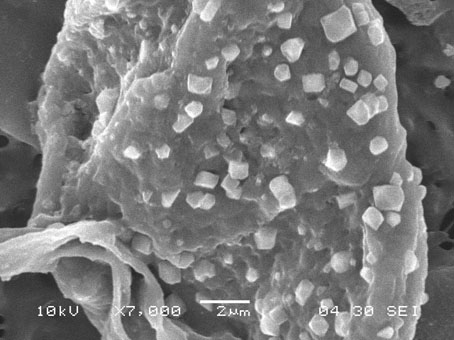

Image

Examples

Embodiment 1

[0035] One of the embodiments of the preparation method of a silver oxide-supported porous membrane of the present invention comprises the following steps:

[0036] (1) Preparation of polyurethane solution: Weigh 15 g of polyester thermoplastic polyurethane particles with a Shore hardness of 55A and 80 g of N,N-dimethylformamide into the reactor, stir at a constant temperature of 25°C for 8 hours, and wait for The thermoplastic polyurethane particles are completely dissolved in the N,N-dimethylformamide solvent to obtain a polyester thermoplastic polyurethane solution;

[0037](2) Prepare the coating solution: add 13 g of 400-mesh activated carbon powder to the polyester thermoplastic polyurethane solution, use a high-speed stirrer to stir for 20 minutes to obtain a uniform coating solution, and then leave the coating for 3 hours. Keep it for later use after defoaming;

[0038] (3) Preparation of activated carbon-based porous film: Coat the coating liquid on the release paper...

Embodiment 2

[0043] One of the embodiments of the preparation method of a silver oxide-supported porous membrane of the present invention comprises the following steps:

[0044] (1) Preparation of polyurethane solution: Weigh 17 g of polyether-type thermoplastic polyurethane particles with a Shore hardness of 60 A and 90 g of N,N-dimethylacetamide into the reactor, stir at a constant temperature of 30°C for 7.5 hours, and wait for The thermoplastic polyurethane particles are completely dissolved to obtain a polyether thermoplastic polyurethane solution;

[0045] (2) Prepare the coating solution: add 15 g of 300-mesh activated carbon powder to the polyether thermoplastic polyurethane solution, stir with a high-speed stirrer for 30 minutes to obtain a uniform coating solution, and keep it for 3.5 hours after standing for defoaming;

[0046] (3) Preparation of activated carbon-based porous film: Coat the coating liquid on the release paper with a thickness of 0.03 mm, and quickly immerse the ...

Embodiment 3

[0051] One of the embodiments of the preparation method of a silver oxide-supported porous membrane of the present invention comprises the following steps:

[0052] (1) Preparation of polyurethane solution: Weigh 18 g of polyester thermoplastic polyurethane particles with a Shore hardness of 60 A and 100 g of N,N-dimethylformamide into the reactor, and stir at a constant temperature of 40°C for 7 hours , the polyurethane solution is obtained after the thermoplastic polyurethane particles are completely dissolved;

[0053] (2) Preparation of coating solution: Add 16 g of 400-mesh activated carbon powder to the polyurethane solution prepared in step (1), stir with a high-speed stirrer for 30 minutes to obtain a uniform coating solution, and let it stand for 4 hours to defoam keep for later use;

[0054] (3) Preparation of activated carbon-based porous film: Coat the coating solution prepared in step (2) on a release paper with a thickness of 0.02 mm, and quickly immerse the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com