Aluminum electrolytic capacitor electrolyte solution and a preparation method thereof and aluminum electrolytic capacitor

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of electrolyte, can solve the problems of large surface tension, increased cost, core heating, etc., to avoid the increase of internal pressure at high temperature, improve the decrease of electrical conductivity, and widen the use temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

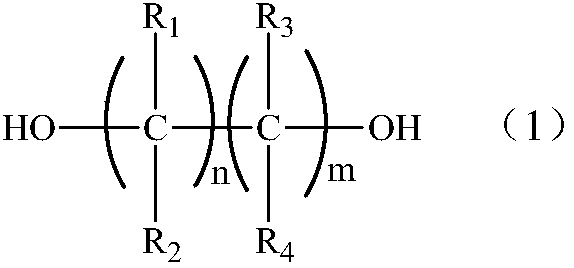

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing an electrolyte for an aluminum electrolytic capacitor. In an embodiment of the method for preparing an electrolyte for an aluminum electrolytic capacitor of the present invention, the preparation method includes the following steps:

[0038] Provide 40-70 parts of main solvent, 10-30 parts of auxiliary solvent, 5-20 parts of solute, and 1-10 parts of additives, wherein the auxiliary solvent contains polyhydric alcohols or polyhydric alcohol derivatives;

[0039] Mix the main solvent and the auxiliary solvent, heat to 40-80°C, add the solute, stir and mix to obtain a mixed solution;

[0040] Continue to heat the mixed solution to 105-115°C, keep it for 60-90 minutes, add the additives, stir and mix, and cool to room temperature to obtain the electrolytic solution of the aluminum electrolytic capacitor.

[0041] In this embodiment, the main solvent and auxiliary solvent are heated to 40-80°C, and then the solute is added. ...

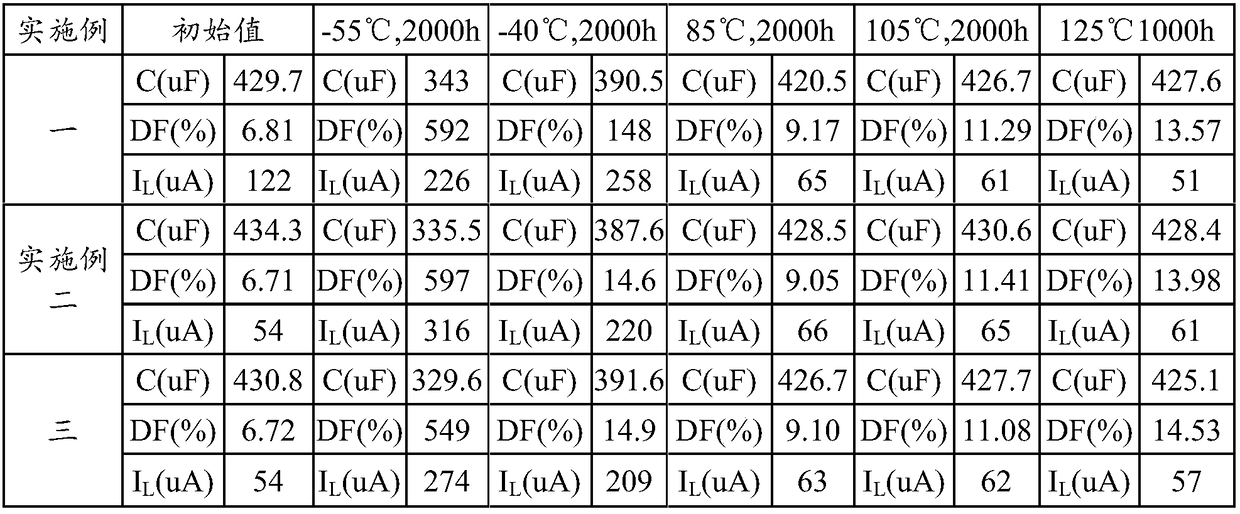

Embodiment 1

[0054] In parts by weight, the formula of aluminum electrolytic capacitor electrolyte is:

[0055] Main solvent: ethylene glycol, 65 parts;

[0056] Auxiliary solvent: 3-methylpentanediol, 20 parts;

[0057] Solute: ammonium sebacate, 1.5 parts; ammonium hydrogen azelate, 1 part; ammonium benzoate, 1 part; branched chain polycarboxylic acid ammonium salt, 10.8 parts;

[0058] Additives: modified polyvinyl alcohol borate, 5 parts; p-nitroanisole, 0.5 parts; ammonium hypophosphite, 0.2 parts.

[0059] Under the condition of air humidity lower than 60%, the electrolytic solution of aluminum electrolytic capacitor is prepared, and the preparation method includes the following steps:

[0060] First, mix 85% of the main solvent and auxiliary solvent and heat to 40°C, add 20% of the solute, stir and dissolve thoroughly to obtain the first mixed solution, continue to heat to 135°C, and keep for 30 minutes;

[0061] Then, the temperature is lowered to 105°C, the remaining solute is added, and the ...

Embodiment 2

[0065] In parts by weight, the formula of aluminum electrolytic capacitor electrolyte is:

[0066] Main solvent: ethylene glycol, 65 parts;

[0067] Auxiliary solvent: 2-methyl 2.4 pentanediol, 15 parts;

[0068] Solute: ammonium sebacate, 1.5 parts; ammonium dodecanedioate, 0.5 parts; ammonium benzoate, 1 part; branched chain polycarboxylic acid ammonium salt, 11.8 parts;

[0069] Additives: polyethylene glycol, 5 parts; p-nitrobenzyl alcohol, 0.5 parts; ammonium hypophosphite, 0.2 parts.

[0070] Under the condition of air humidity lower than 60%, the electrolytic solution of aluminum electrolytic capacitor is prepared, and the preparation method includes the following steps:

[0071] First, mix 85% of the main solvent and auxiliary solvent and heat to 60°C, add 15% of the solute, stir and dissolve thoroughly to obtain the first mixed solution, continue to heat to 140°C, and keep it for 40 minutes;

[0072] Then, the temperature is lowered to 105°C, the remaining solute is added, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com