Spherical titanium dioxide preparation method, and applications thereof in automatically cleaning coating layers

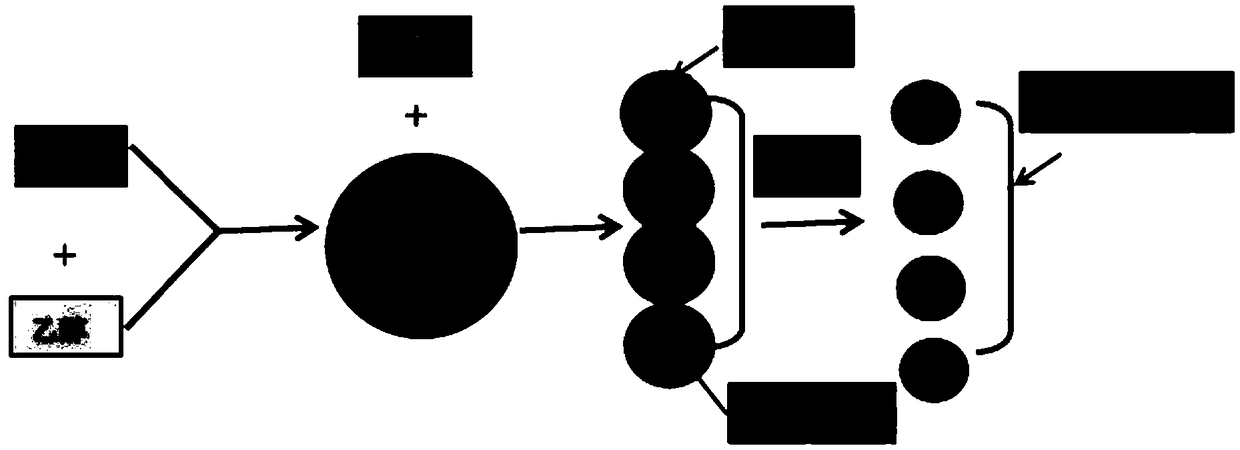

A titanium dioxide, spherical technology, applied in the preparation method of spherical titanium dioxide and its application in self-cleaning coatings, can solve the problems of unfavorable influence of environmental producers, complex synthesis steps of nano oxide particles, etc., and achieve good corrosion resistance and Self-cleaning ability, excellent self-cleaning ability, good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 A kind of spherical titanium dioxide and preparation method thereof

[0048] The following components are included: 5% urea ethanol solution (solution A), 30% urea aqueous solution (solution B), tetrabutyl titanate and ethanol. Wherein, the volume ratio of tetrabutyl titanate and ethanol used is 1:2.

[0049] Preparation:

[0050] (1) Take 20ml tetrabutyl titanate and add 40ml ethanol, stir evenly;

[0051] (2) Add 10ml solution A, 2ml solution B, stir for 2h;

[0052] (3) The above-mentioned sol is subjected to gel transition at room temperature, and the gelation time is 72h;

[0053] (4) Grinding the dried sol and calcining at 400°C for 3h;

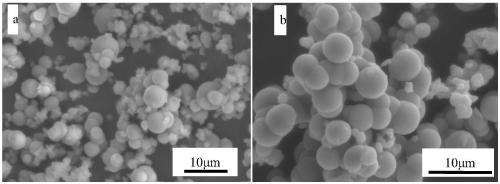

[0054] (5) Grinding the calcined titanium dioxide particles for later use (No. 1, see image 3 a).

Embodiment 2

[0055] Embodiment 2 A kind of spherical titanium dioxide and preparation method thereof

[0056] It includes the following components: 5% urea ethanol solution (solution A), tetrabutyl titanate and ethanol. Wherein, the volume ratio of tetrabutyl titanate and ethanol used is 1:2.

[0057] Preparation:

[0058] (1) Take 20ml tetrabutyl titanate and add 40ml ethanol, stir evenly;

[0059] (2) Add 8ml of solution A and stir for 2h;

[0060] (3) The above-mentioned sol is subjected to gel transition at room temperature, and the gelation time is 72h;

[0061] (4) Grinding the dried sol and calcining at 400°C for 3h;

[0062] (5) Grinding the calcined titanium dioxide particles for later use (No. 2, see image 3 b)

Embodiment 3

[0063] Embodiment 3 A kind of spherical titanium dioxide and preparation method thereof

[0064] It includes the following components: 5% urea ethanol solution (solution A), tetrabutyl titanate and ethanol. Wherein, the volume ratio of tetrabutyl titanate and ethanol used is 1:2.

[0065] Preparation:

[0066] (1) Take 20ml tetrabutyl titanate and add 40ml ethanol, stir evenly;

[0067] (2) Add 10ml of solution A and stir for 2h;

[0068] (3) The above-mentioned sol is subjected to gel transition at room temperature, and the gelation time is 72h;

[0069] (4) Grinding the dried sol and calcining at 400°C for 3h;

[0070] (5) Grinding the calcined titanium dioxide particles for later use (No. 3, see image 3 c)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com