Microwave Activation of Blast Furnace Slag

A microwave activation, blast furnace slag technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as long reaction time, reduce purification energy consumption, good large-scale utilization potential, and improve efficiency.

Inactive Publication Date: 2019-10-01

SICHUAN UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The method comprises the following steps: (1) mixing and roasting titanium-containing blast furnace slag and ammonium sulfate to obtain roasted slag and ammonia gas, and absorbing the ammonia gas with water to obtain ammonia water; (2) leaching the roasted slag with water and filtering to obtain leaching liquid and leaching slag; (3) react the leaching slag of step 2, the ammonia water of step 1 and carbon dioxide to obtain mineralized slag and mineralized mother liquor; (4) adjust the pH of the solution with the ammonia water of step 1 for the leaching liquid of step 2, precipitate and filter step by step to obtain Metatitanic acid and aluminum hydroxide precipitation and magnesium-rich solution; (5) the magnesium-rich solution in step 4, the ammoniacal liquor of step 1 and carbon dioxide react to obtain magnesium carbonate precipitation and mineralization mother liquor; (6) the step 3 and 5 The mineralized mother liquor is mixed and evaporated, cooled, and crystallized to obtain ammonium sulfate solid, which is recycled; (7) the precipitates in step 4 are calcined respectively to obtain TiO 2 and Al 2 o 3 , but the response time is still longer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

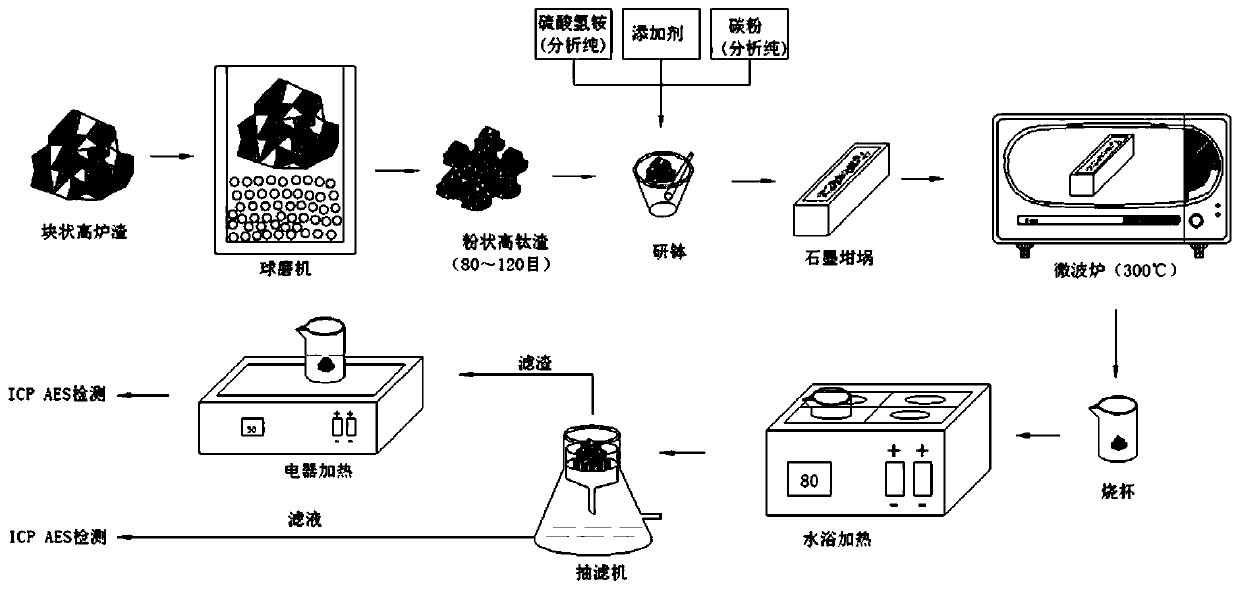

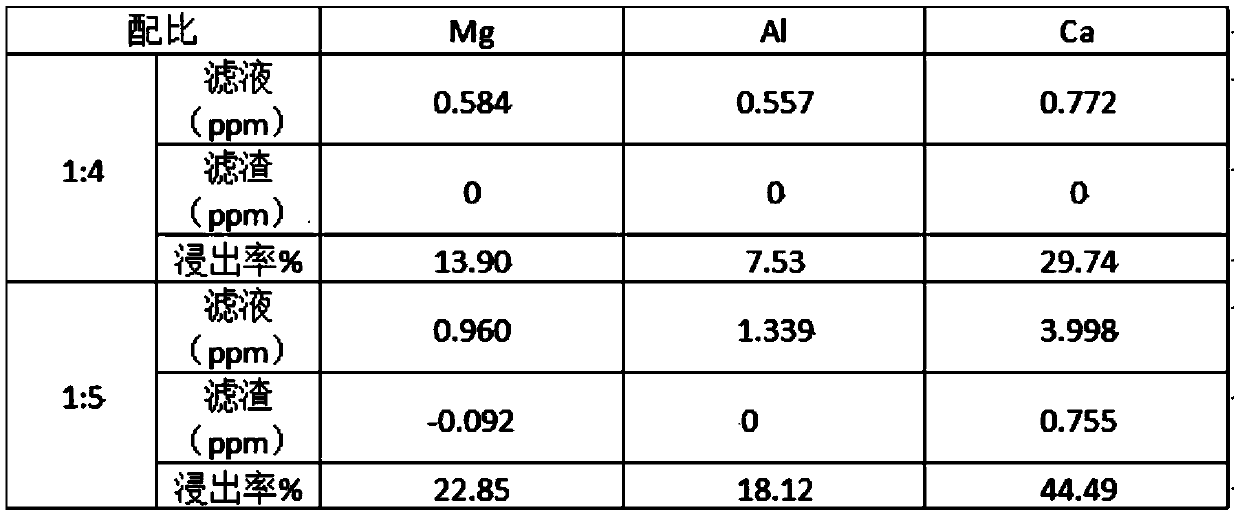

The invention relates to a microwave activation method for blast furnace slag, which belongs to the technical field of blast furnace slag activation and carbon dioxide sequestration. The method for microwave activation of blast furnace slag of the present invention comprises the following steps: a. mixing blast furnace slag, ammonium salt and catalyst to obtain a mixed material; the catalyst is at least one of barium titanate and lead titanate, and the ammonium salt It is at least one of ammonium sulfate and ammonium bisulfate; b. heating the mixed material to 250-500°C with microwaves, and heat-retaining reaction for 5-10 minutes; c. adding water to the material after heat-retaining reaction in step b, dissolving , filtering to obtain filtrate 1 and filter residue 1, the filtrate 1 contains activated calcium and magnesium ions. The present invention uses microwave technology in conjunction with a specific catalyst to realize microwave intensification and catalysis in the blast furnace slag activation process, and activates calcium and magnesium ions in blast furnace slag within a relatively short processing time, thereby greatly reducing energy consumption for purification and improving efficiency .

Description

technical field The invention relates to a microwave activation method for blast furnace slag, which belongs to the technical field of blast furnace slag activation and carbon dioxide sequestration. Background technique Global carbon dioxide emissions will hit a record 410×10 in 2017 8 t, its large amount of emission is the main factor leading to global warming, the El Nino phenomenon, and the prolongation of the high temperature climate in Chengdu year after year. By 2050, carbon capture and storage (CCS) will account for 19% of the total global carbon dioxide emission reduction, making it the second largest emission reduction technology after improving energy efficiency. CCS technology is mainly composed of two parts: carbon capture and carbon storage. Among the traditional storage technologies, there are mainly geological storage and ocean storage. The advantage of geological storage is that it has a large storage capacity and can be stored permanently. The disadvantage...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09B3/00C01B32/55

CPCC01B32/55B09B3/00B09B3/40Y02W30/20

Inventor 王烨韩子柯陈辉袁熙志杨林钟艳君许德华王辛龙

Owner SICHUAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com