A method for synergistically purifying polysilicon with volatile slag gas

A volatile, polycrystalline silicon technology, applied in the field of metallurgy, can solve the problems of low boron impurity content, long processing time, long processing time, etc., and achieve the effects of reducing boron impurities, low cost, and reducing energy consumption for purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

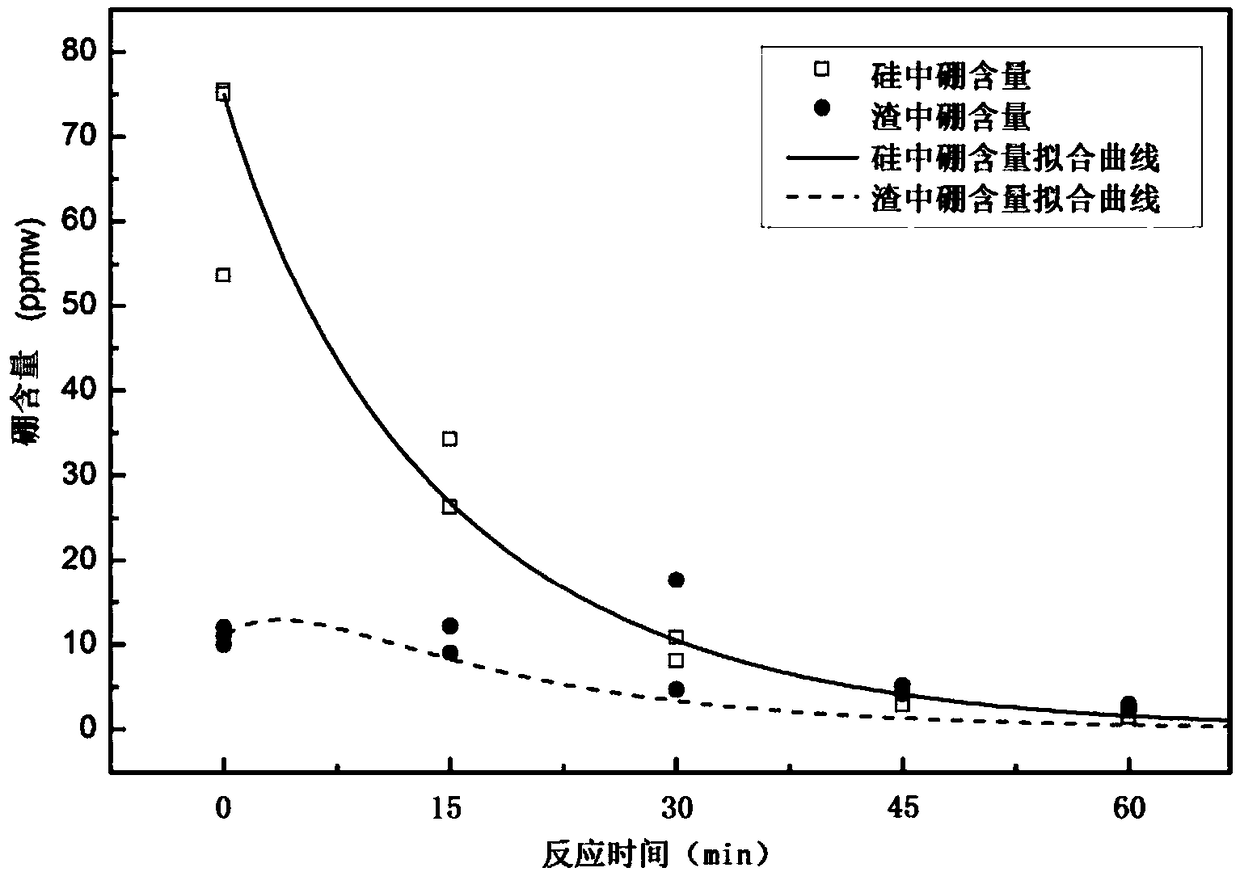

Embodiment 1

[0040] 1) Weigh 5g of raw silicon with a boron content of 75ppmw, according to 23.3mol% SiO 2 -46.7mol% CaCl 2 The ratio of -30mol% CaO weighs a total of 10g of volatile slag-based slagging agents, which ensures that in the volatile slag-based slagging agents, SiO 2The molar percentage is 23.3%, CaCl 2 The molar percentage of CaO is 46.7%, and the molar percentage of CaO is 30%.

[0041] 2) The raw silicon and the ground and mixed volatile slag-based slagging agent were pre-melted at 1450° C. respectively.

[0042] 3) After adding the slag to silicon, place it in a heating furnace and melt it at 1550°C under an argon atmosphere. After it is completely melted, insert an ammonia gas pipe into the melt to blow air. The gas blown in is ammonia gas, and the flow rate of ammonia gas is 100mL / min , blowing time 60min.

[0043] 4) After the air blowing is completed, quenching and cooling are carried out.

[0044] 5) The silicon and slag were separated and sampled, and then digest...

Embodiment 2

[0053] 1) Weigh 5g of raw silicon with a boron content of 75ppmw, according to 20wt% SiO 2 -40wt% MgCl 2 The ratio of -40wt% CaO weighs 10 g of volatile slag-based slagging agents in total.

[0054] 2) The raw silicon and the ground and mixed volatile slag-based slagging agent are pre-melted at 1450-1550° C. respectively.

[0055] 3) Put the slag into silicon and put it in a heating furnace to melt at 1450°C under an argon atmosphere. After complete melting, insert an ammonia gas pipe into the melt for blowing. The blown gas is ammonia, and the flow rate of ammonia gas is 100mL / min , blowing time 60min.

[0056] 4) After the air blowing is completed, quenching and cooling are carried out.

[0057] 5) After the silicon and slag were separated and sampled, they were digested for ICP detection, and the boron content was reduced to 41.9ppmw.

Embodiment 3

[0065] 1) Weigh 5g of raw silicon with a boron content of 80ppmw, according to 20mol% SiO 2 -40wt% BaCl 2 The ratio of -40wt% CaO weighs 10 g of volatile slag-based slagging agents in total.

[0066] 2) The raw silicon and the ground and mixed volatile slag-based slagging agent are pre-melted at 1450-1550° C. respectively.

[0067] 3) Put the slag into silicon and put it in a heating furnace to melt at 1450°C under an argon atmosphere. After complete melting, insert an ammonia gas pipe into the melt for blowing. The blown gas is ammonia, and the flow rate of ammonia gas is 100mL / min , blowing time 60min.

[0068] 4) After the air blowing is completed, quenching and cooling are carried out.

[0069] 5) After the silicon and slag were separated and sampled, they were digested for ICP detection, and the boron content was reduced to 49.5ppmw.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com