Heavy oil hydrogenation system and a hydrogenation method capable of self-producing hydrogen

A heavy oil hydrogenation and hydrogen technology, applied in the field of oil refining and chemical industry, can solve the problems of poor device integration, large device load, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

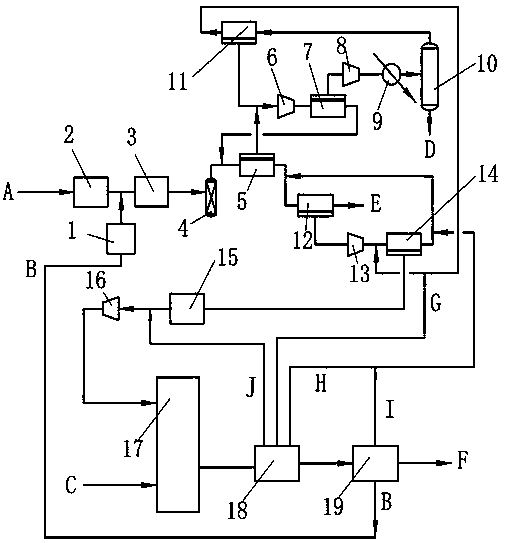

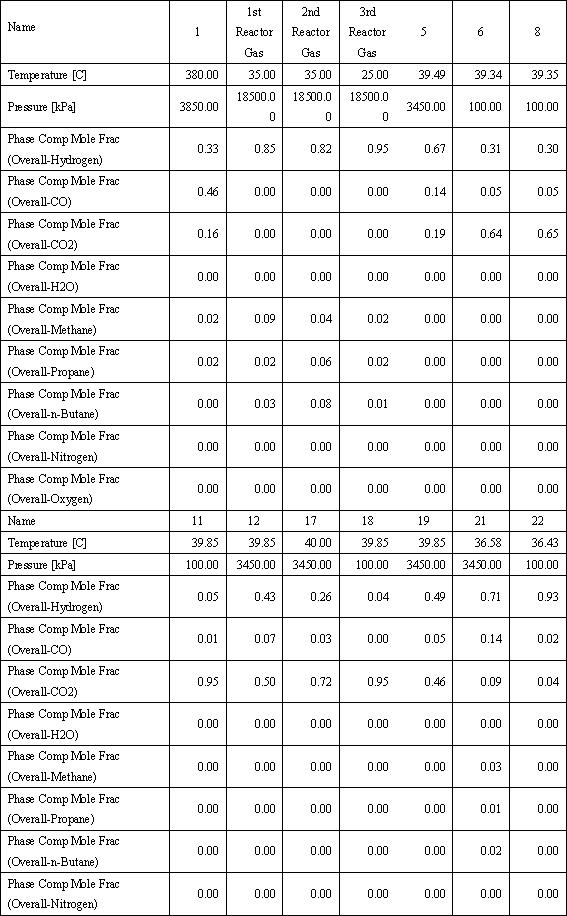

[0049] The flow chart of this embodiment is attached figure 1 . Raw coal A is pulverized and dust-removed and then pneumatically conveyed into the coal gasification reaction unit 2, and the hydrogenated tail oil B from the fractionation unit 19 enters the heavy oil gasification reaction unit 1. The heavy oil gasification reaction unit 1 and the coal gasification reaction unit 2 adopt fluidized bed reactors. In the coal gasification reaction unit 2, the pulverized coal is converted into coal gas, carbon dioxide, etc. during the rising process through the lifting of the transport gas and oxygen, and then the ash is removed by water washing, and the deep conversion is carried out. The reaction temperature of coal gasification reaction unit 2 is 1475°C, the pressure is 3.85MPa, and the space velocity is 10h -1 . The generated gas from the coal gasification reaction unit 2 enters the water gas shift reaction unit 3 for a shift reaction to convert water vapor into hydrogen. The ...

Embodiment 2

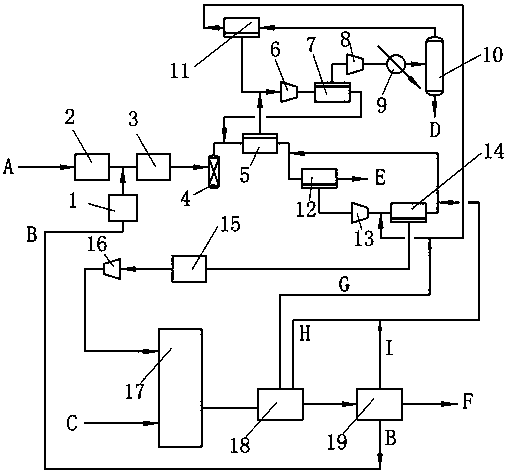

[0056] The flow chart of this embodiment is attached figure 2 . Compared with the flow process of Example 1, this example differs in that the heavy oil hydrogenation reaction unit includes two reaction zones connected in series, the first reaction zone and the second reaction zone, and one ebullating bed reactor is set in each reaction zone , the first ebullating bed reactor discharges the sulfur-rich flash gas G from the top, and the second ebullating bed reactor discharges the hydrogen-rich flash gas H from the top; the flash gas G enters the second hydrogen separation membrane 14; the flash gas H and the second The retentate gas from the hydrogen separation membrane 14 returns to the inlet of the first hydrogen separation membrane 12 after merging.

[0057] The operating temperature of the first ebullating bed reactor and the second ebullating bed reactor is 400°C, and the hydrogenation conversion rate of residual oil is 60%. Hydrogen feedstock.

[0058] The material ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com