Welding method for increasing surface hardness of capping bead of wear resistant steel plate

A technology of wear-resistant steel plate and cover weld bead, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of component bearing capacity reduction, weld cracking, weld wear, etc., to improve wear resistance, welding The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

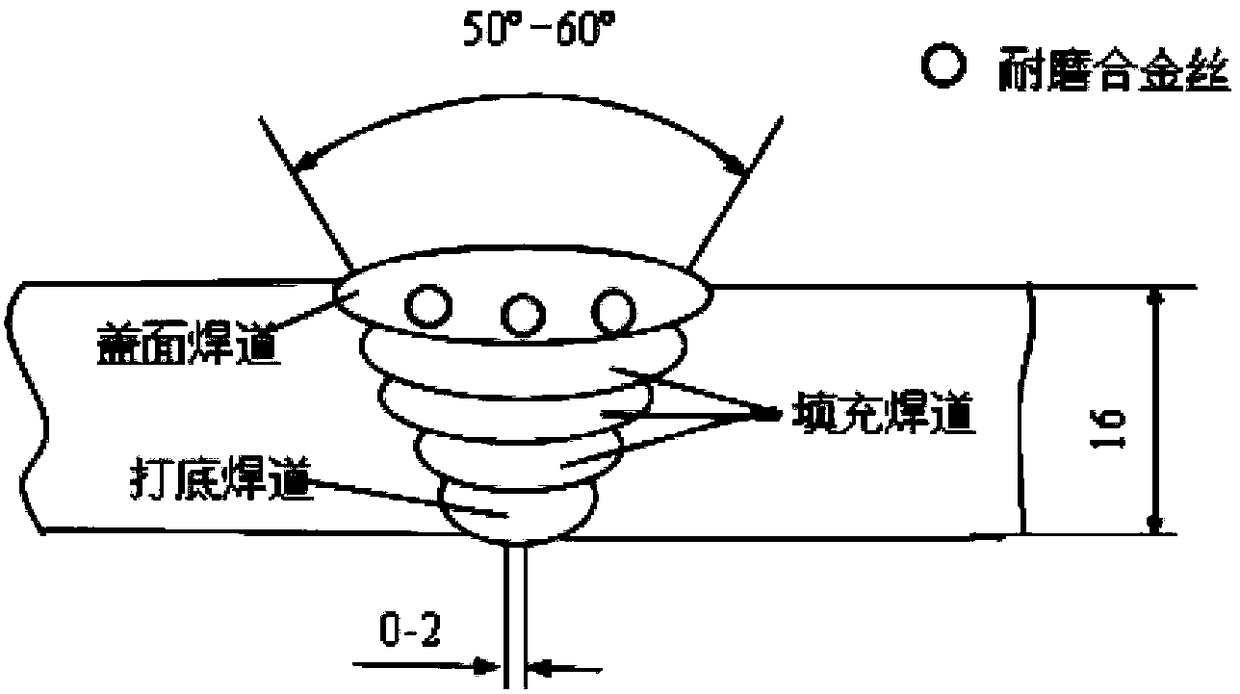

[0026] (1) The hardness level is HB360 low-alloy high-strength wear-resistant steel plate, and it is combined with the wear-resistant steel plate of the same plate thickness. The combination of thick plate is 16mm+16mm, the welding groove and welding bead arrangement are shown, and the position of the wear-resistant alloy wire is as follows figure 1 As shown, the size of the test plate is 500mm×400mm×16mm.

[0027] (2) The groove adopts V-shaped groove, the groove angle is 50°-60°, the groove gap is 0-2mm, and the blunt edge is 0-0.5mm;

[0028] (3) Bottom welding and filling welding: match ER69-G gas shielded welding wire with Φ1.2mm and tensile strength Rm≥690MPa, use argon-rich mixed gas (80%Ar+20%CO) 2 Mixed gas) shielded welding is used to perform bottoming welding and filling welding in the weld groove of wear-resistant steel plates; the preheating temperature before welding is 80 °C, and the preheating range is not less than 75mm on both sides of the welding groove; bo...

Embodiment 2

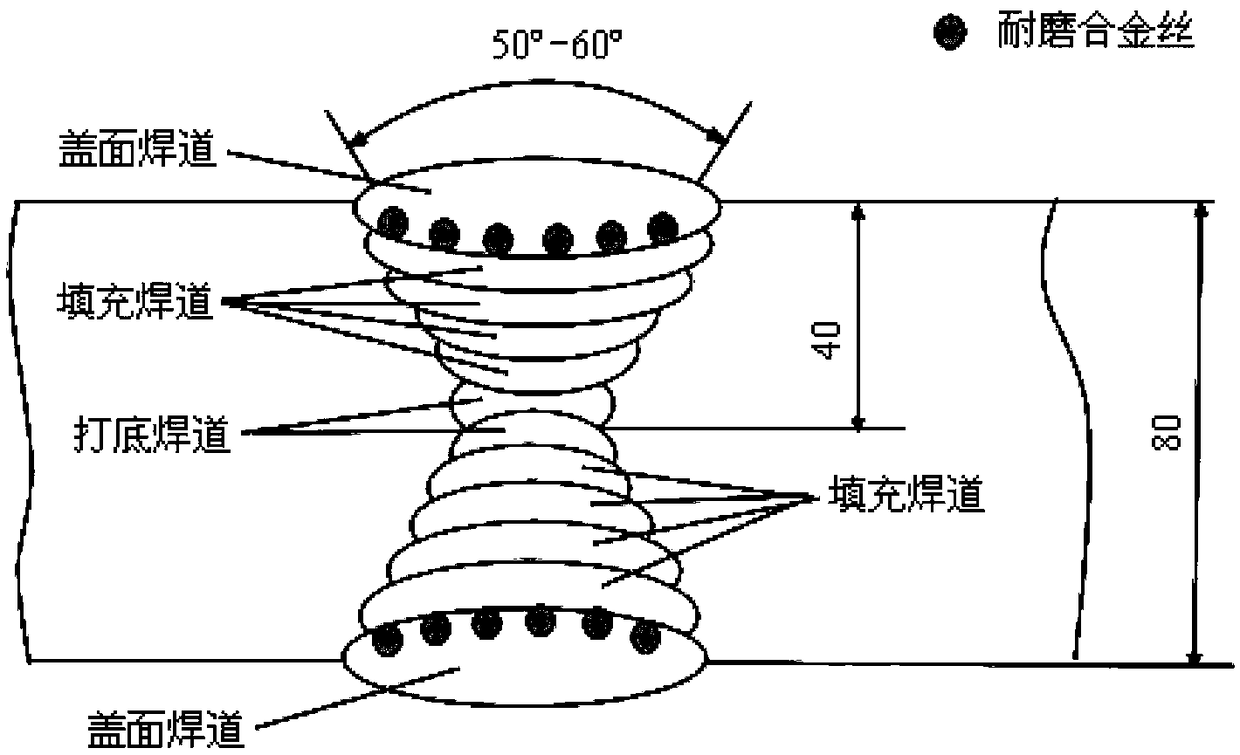

[0033] (1) The hardness level is HB360 low-alloy high-strength wear-resistant steel plate, and it is combined with the wear-resistant steel plate of the same plate thickness. The combination of thick plate is 80mm+80mm, the welding groove and welding bead arrangement are shown, and the position of the wear-resistant alloy wire is as follows figure 2 As shown, the size of the test plate is 500mm×400mm×80mm.

[0034] (2) The groove adopts X-shaped groove, the groove angle is 50°-55°, the groove gap is 0-2mm, and the blunt edge is 0.5-1mm;

[0035](3) Bottom welding and filling welding: match ER69-G gas shielded welding wire with Φ1.2mm and tensile strength Rm≥690MPa, use argon-rich mixed gas (80%Ar+20%CO) 2 Mixed gas) shielded welding is used to perform bottoming welding and filling welding in the weld groove of wear-resistant steel plates; the preheating temperature before welding is 100 °C, and the preheating range is not less than 240mm on both sides of the welding groove; ...

Embodiment 3

[0040] (1) The hardness level is HB400 low-alloy high-strength wear-resistant steel plate, which is combined with the wear-resistant steel plate of the same plate thickness. The combination of thick plate is 16mm+16mm, the welding groove and welding bead arrangement are shown, and the position of the wear-resistant alloy wire is as follows figure 1 As shown, the size of the test plate is 500mm×400mm×16mm.

[0041] (2) The groove adopts V-shaped groove, the groove angle is 50°-60°, the groove gap is 0-2mm, and the blunt edge is 0-0.5mm;

[0042] (3) Bottom welding and filling welding: match ER69-G gas shielded welding wire with Φ1.2mm and tensile strength Rm≥690MPa, use argon-rich mixed gas (80%Ar+20%CO) 2 Mixed gas) shielded welding is used to perform bottoming welding and filling welding in the weld groove of wear-resistant steel plates; the preheating temperature before welding is 80 °C, and the preheating range is not less than 75mm on both sides of the welding groove; bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com