Copper alloy wire and preparation method thereof

A technology of copper alloy wire and copper alloy, which is applied in the field of alloys, can solve problems such as broken wires, poor drawability, and substandard drawability. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

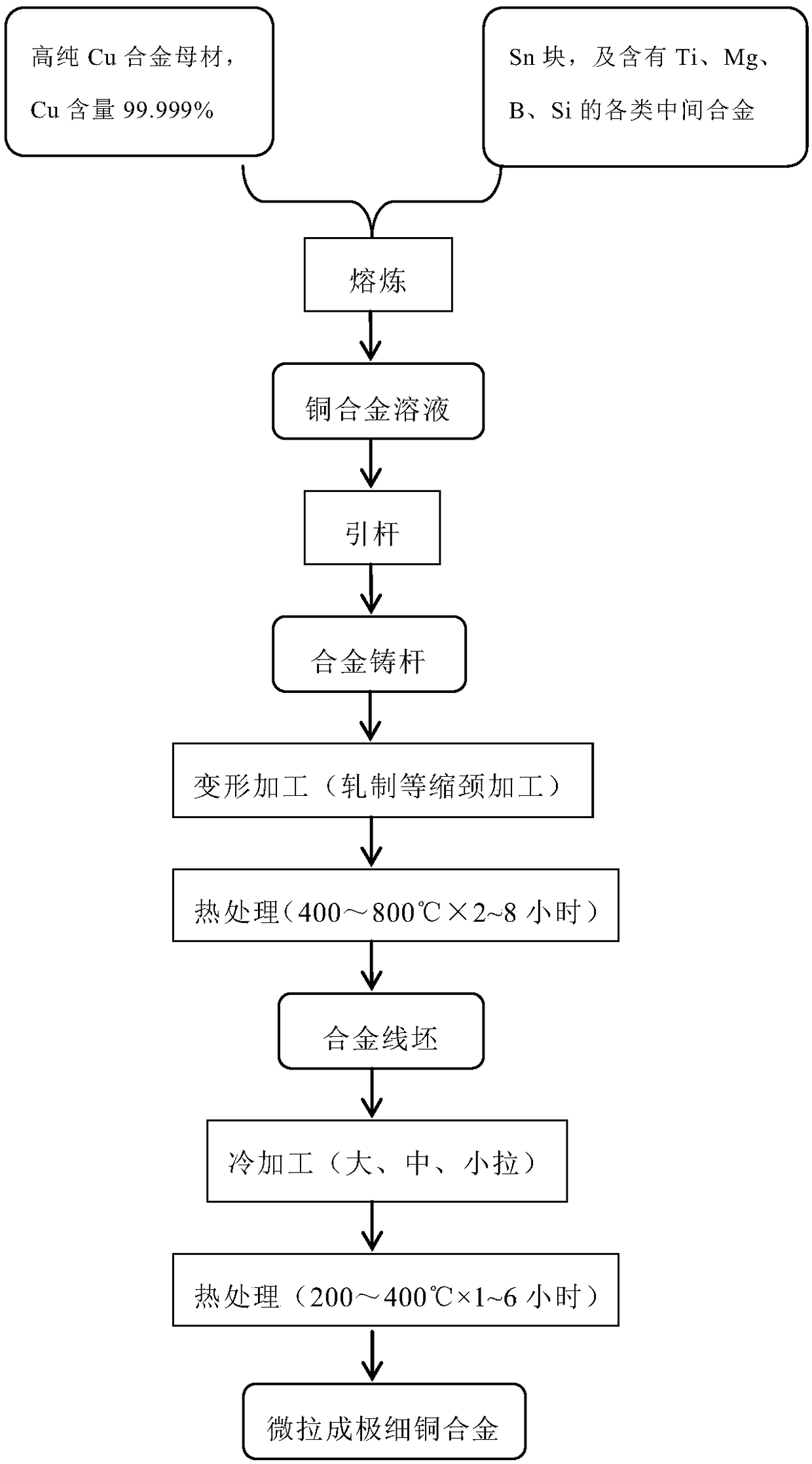

Method used

Image

Examples

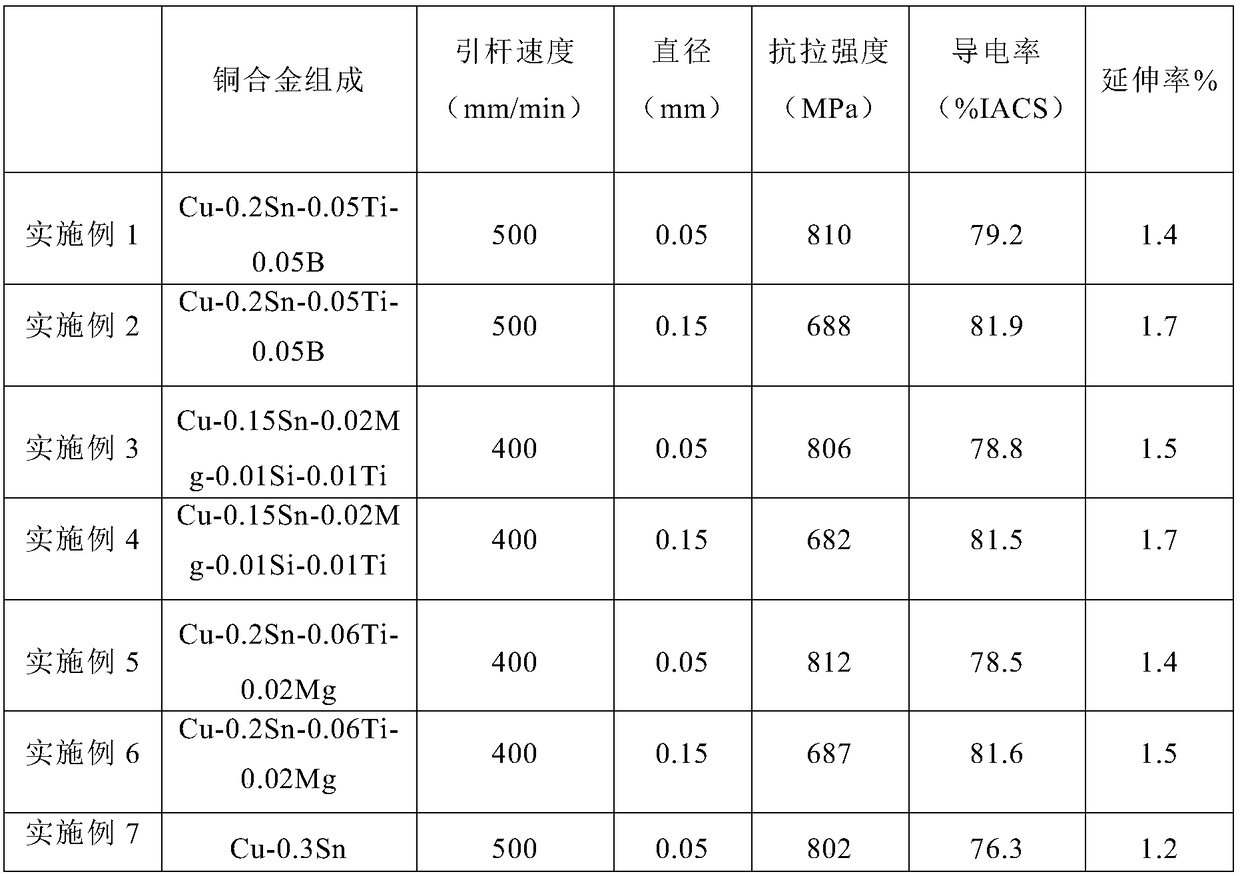

Embodiment 1

[0048] The copper alloy wire rod contains the following elements in mass percentage: 0.2% Sn, 0.05% Ti, 0.05% B, the balance is Cu, and the mass ratio of Sn / (Ti+B)=2:1.

[0049] (1) Weigh the tin block, copper-titanium master alloy, copper-boron master alloy and copper base material according to the mass percentage of Sn, Ti, B and Cu elements in the copper alloy wire (the Cu content is 99.999%).

[0050] (2) Place the weighed copper base material in a graphite crucible with an inert atmosphere (vacuum or nitrogen, argon and other inert atmospheres) for induction heating and melting. After the copper base material is melted, add the weighed tin block, copper titanium master alloy and copper-boron master alloy to form molten copper alloy liquid;

[0051] Lay a carbon powder layer with a thickness of 15mm on the surface of the copper alloy liquid. The carbon powder layer can effectively avoid the introduction of impurity elements such as hydrogen and oxygen in the ambient air. U...

Embodiment 2

[0056] The copper alloy wire rod contains the following elements in mass percentage: 0.2% Sn, 0.05% Ti, 0.05% B, the balance is Cu, and the mass ratio of Sn / (Ti+B)=2:1.

[0057] The preparation method of this embodiment is the same as that of Example 1, except that:

[0058] Step (4) The copper alloy wire blank is subjected to large drawing, medium drawing and small drawing in sequence to obtain a copper alloy wire rod with a wire diameter of 0.15mm. The process is as follows: large drawing at a drawing speed of 10m / s until the wire diameter is about 3mm , under the drawing speed of 10m / s, the wire diameter is about 1mm; after the middle drawing, before the small drawing, in the argon atmosphere, heat to 300 ℃ for 4 hours for bright annealing, the elongation of the alloy wire after annealing is 28 %; Finally, a copper alloy wire with a wire diameter of 0.15mm is drawn at a speed of 19m / s.

[0059] The content of hydrogen in the copper alloy wire prepared in this embodiment is...

Embodiment 3

[0061] Copper alloy wire rod, containing the following elements in mass percentage: 0.15% Sn, 0.02% Mg, 0.01% Si, 0.01% Ti, the balance is Cu, the mass ratio of Sn / (Mg+Si+Ti)≈3~4:1 .

[0062] (1) Weigh the tin block, copper-magnesium master alloy, copper-silicon master alloy, copper-titanium master alloy and copper base material according to the mass percentage of Sn, Mg, Si, Ti and Cu elements in the copper alloy wire (Cu content rate is 99.999%) %).

[0063] (2) Place the weighed copper base material in a graphite crucible with an inert atmosphere (vacuum or nitrogen, argon and other inert atmospheres) for induction heating and melting. After the copper base material is melted, add the weighed tin block, copper magnesium Master alloy, copper-silicon master alloy and copper-titanium master alloy to form molten copper alloy liquid;

[0064] Lay a carbon powder layer with a thickness of 15mm on the surface of the copper alloy liquid. The carbon powder layer can effectively av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com