Preparation method of fluorescent powder with controllable luminescent property and prepared fluorescent powder

A technology for luminescent properties and phosphors, applied in the directions of luminescent materials, chemical instruments and methods, etc., can solve the problems of uncontrollable luminescent properties of phosphors, difficult to achieve controllable modulation, and complicated preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

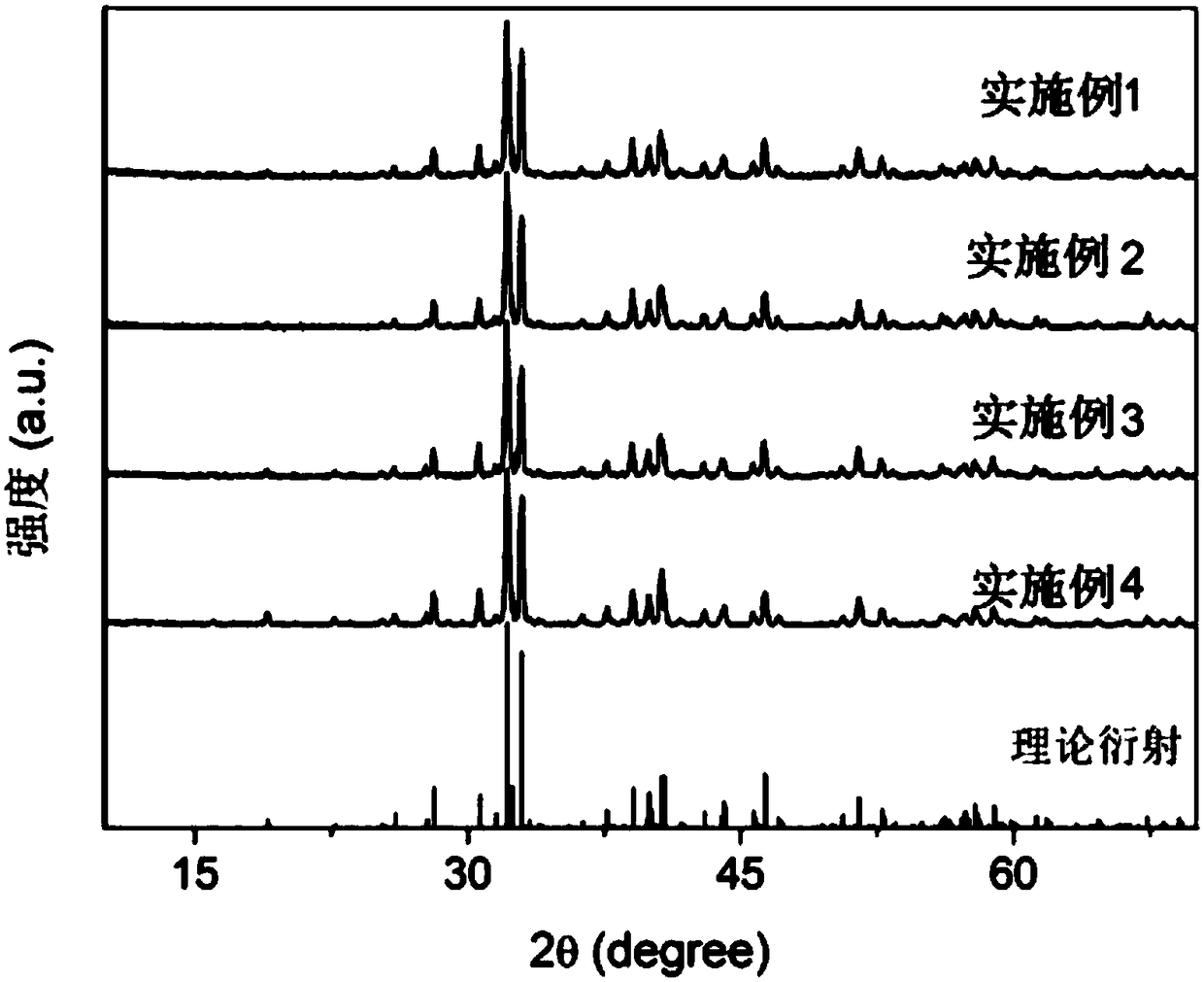

Embodiment 1

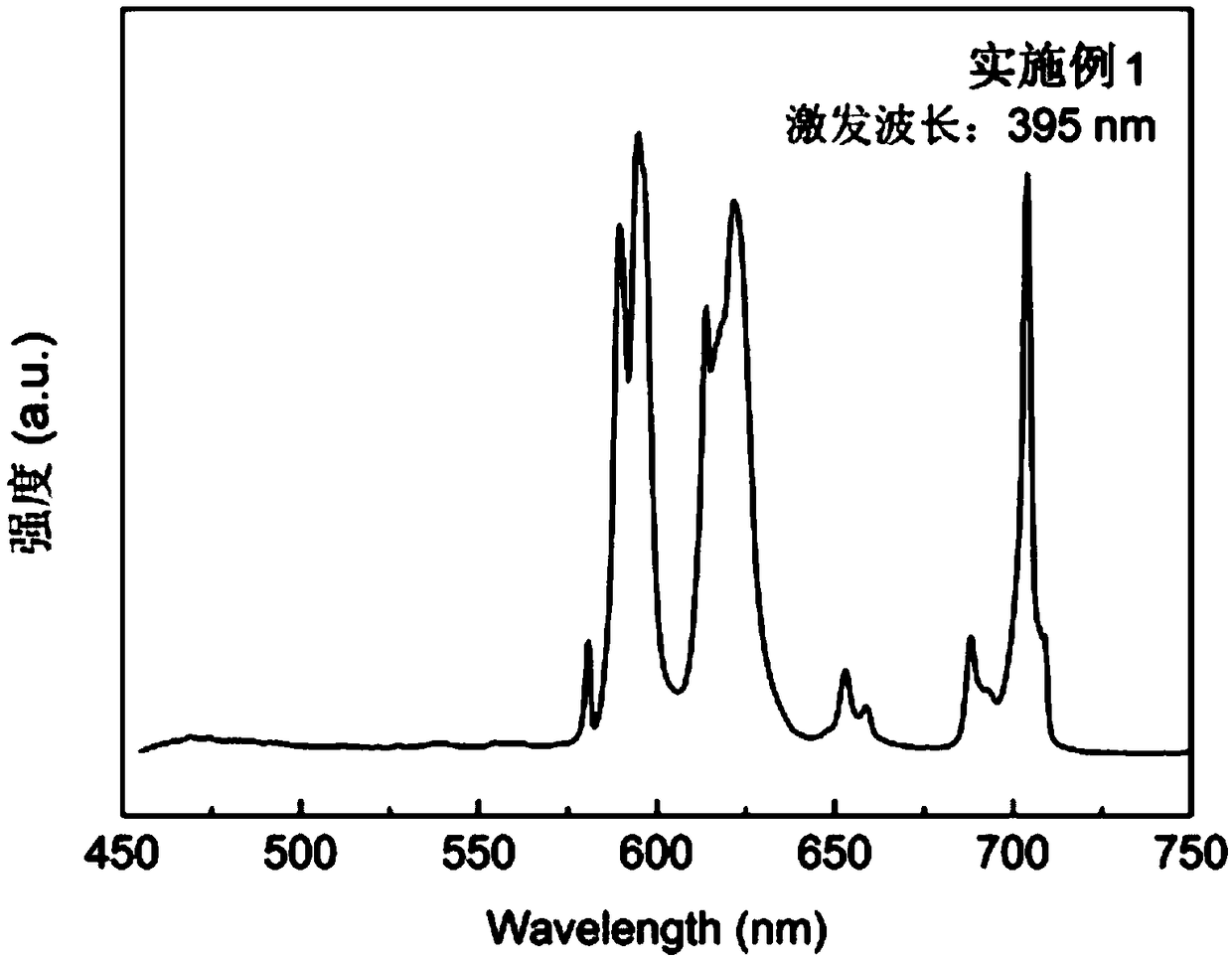

[0042] Preparation (Eu 2+ 0.005 Eu 3+ 0.045 A + 0.045 m 0.905 ) 2 SiO 4 Phosphor powder, the steps are as follows:

[0043] in Eu 2 o 3 , Li 2 CO 3 , CaCO 3 , Sr(NO 3 ) 2 and SiO 2 As the initial raw material, the molar ratio of Eu:Li:(Ca+Sr):Si was 0.1:0.09:1.81:1, and the raw materials were wet mixed with alcohol solution for 1 h, and dried in a fume hood at room temperature. Obtain a uniform mixed powder;

[0044] Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter at 1100 °C for 2 h in an air atmosphere, press it into a block after grinding, and then sinter at 1450 °C for 6 h in an air atmosphere, cool down to room temperature, and grind to an average particle size of 0.5-15 μm.

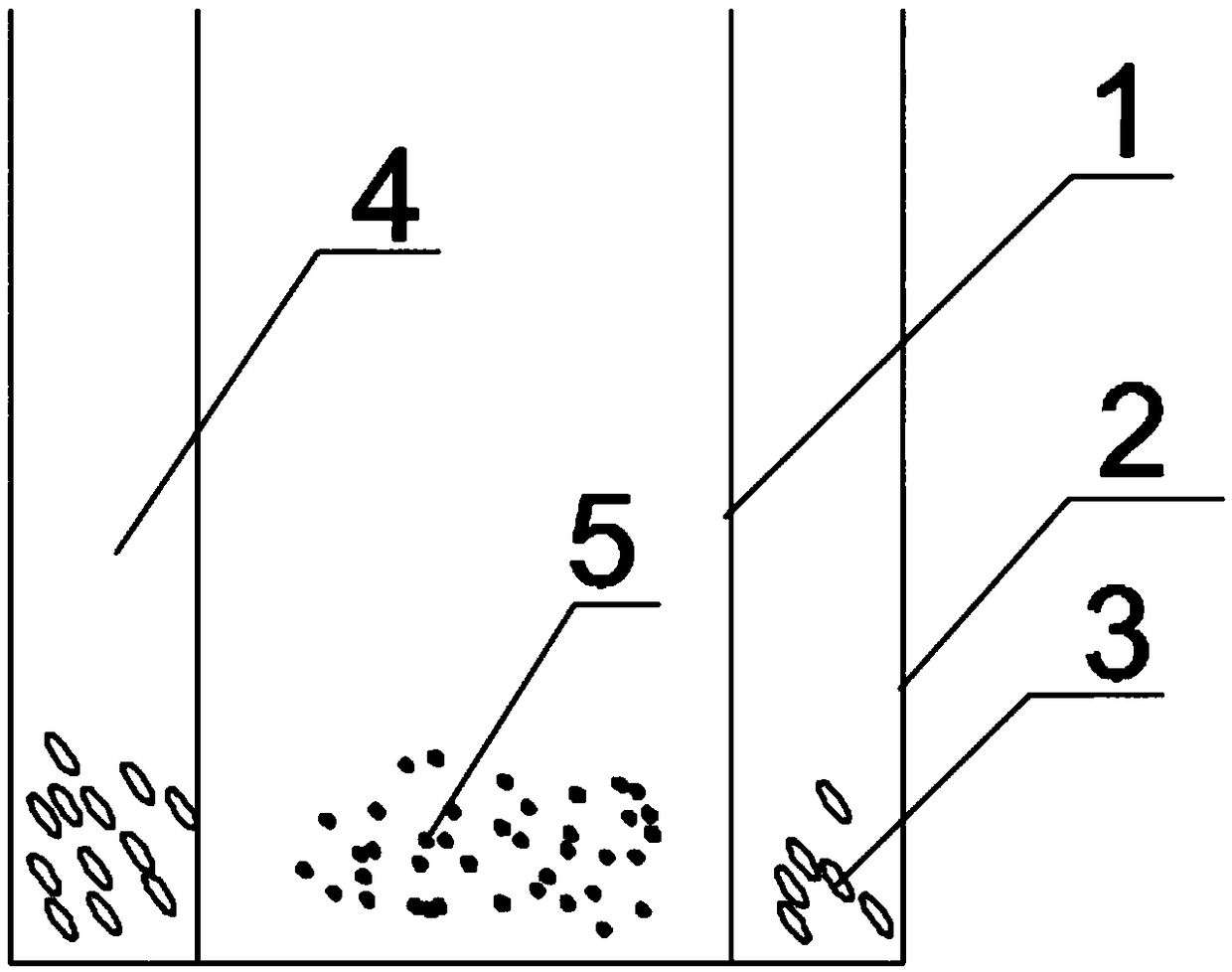

[0045] Put the above powder into a small corundum crucible, cover the small corundum crucible cover (not sealed), put the small corundum crucible into a large corundum crucible with carbon powder, cover the cover as a microwave double-layer rea...

Embodiment 2

[0048] Preparation (Eu 2+ 0.02 Eu 3+ 0.1 A + 0.1 m 0.78 ) 2 SiO 4 Phosphor powder, the steps are as follows:

[0049] in Eu 2 o 3 , Li 2 CO 3 , CaCO 3 、BaCO 3 and SiC 8 h 20 o 4 As the initial raw materials, the molar ratio of Eu:Li:(Ca+Ba):Si was 0.24:0.2:1.56:1, and the raw materials were wet mixed with alcohol solution for 1 h, and dried in a fume hood at room temperature. Obtain a uniform mixed powder;

[0050] Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter at 800 °C for 5 h in an air atmosphere, press it into a block after grinding, and then sinter at 1300 °C for 10 h in an air atmosphere, cool down to room temperature, and grind to an average particle size of 0.5-15 μm.

[0051] Put the above powder into a small corundum crucible, cover the small corundum crucible cover (not sealed), put the small corundum crucible into a large corundum crucible with silicon carbide powder, cover the cover as a microwave double-l...

Embodiment 3

[0054] Preparation (Eu 2+ 0.1 Eu 3+ 0.08 A + 0.08 m 0.74 ) 2 SiO 4 Phosphor powder, the steps are as follows:

[0055] in Eu 2 o 3 、K 2 CO 3 , CaCO 3 , SrCO 3 and SiO 2 As the initial raw material, the molar ratio of Eu:K:(Ca+Sr):Si was 0.36:0.16:1.48:1, and the raw materials were wet mixed with alcohol solution for 1 h, and dried in a fume hood at room temperature. Obtain a uniform mixed powder;

[0056] Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter at 1100 °C for 3 h in an air atmosphere, press it into a block after grinding, and then sinter at 1450 °C for 6 h in an air atmosphere, cool down to room temperature, and grind to an average particle size of 0.5-15 μm.

[0057] Put the above powder into a small corundum crucible, cover the small corundum crucible cover (not sealed), put the small corundum crucible into a large corundum crucible with carbon powder, cover the cover as a microwave double-layer reactor, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com