High-strength LCP composite and preparation method thereof

A composite material and high-strength technology, applied in the field of high-strength LCP composite materials and their preparation, can solve the problems of low mechanical properties of liquid crystal polymers, easy generation of static electricity in electronic components, and high glass fiber consumption, and achieve antistatic and mechanical properties. Improve and avoid the effect of glass fiber exposure and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

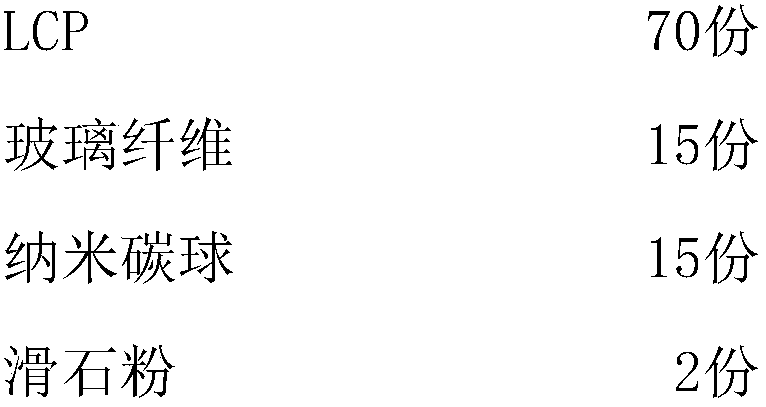

[0034] A high-strength LCP composite material, comprising the following raw materials in parts by weight:

[0035]

[0036]

[0037] The average particle size of the carbon nanospheres is 80nm, and the BET specific surface area is 1000m 2 / g.

[0038] Wherein, the LCP is preferably a thermotropic liquid crystal polymer with a number average molecular weight of 8000.

[0039] Wherein, the diameter of the glass fiber is 16.7 μm, and the aspect ratio is 25:1.

[0040] Wherein, the carbon nanospheres are prepared by the following method:

[0041] A, take bamboo fiber powder, carry out pre-carbonization treatment in inert gas atmosphere, namely obtain carbon precursor;;

[0042] B. After the carbon precursor is cooled to room temperature, it is immersed in an aqueous solution of potassium hydroxide with a mass concentration of 10% for 1 hour, then the carbon precursor is taken out and freeze-dried, and then the freeze-dried carbon precursor is placed under an inert gas atmos...

Embodiment 2

[0053] A high-strength LCP composite material, comprising the following raw materials in parts by weight:

[0054]

[0055] The average particle size of the nano-carbon spheres is 90nm, and the BET specific surface area is 942.8m 2 / g.

[0056] Wherein, the LCP is preferably a thermotropic liquid crystal polymer with a number average molecular weight of 6000.

[0057] Wherein, the diameter of the glass fiber is 11 μm, and the aspect ratio is 30:1.

[0058] Wherein, the carbon nanospheres are prepared by the following method:

[0059] A, take bamboo fiber powder, carry out pre-carbonization treatment in inert gas atmosphere, namely obtain carbon precursor;;

[0060] B. After the carbon precursor is cooled to room temperature, it is immersed in an aqueous potassium hydroxide solution with a mass concentration of 8% for 1.5 hours, then the carbon precursor is taken out and freeze-dried, and then the freeze-dried carbon precursor is placed in an inert gas atmosphere Under a...

Embodiment 3

[0071] A high-strength LCP composite material, comprising the following raw materials in parts by weight:

[0072]

[0073] The average particle diameter of the carbon nanospheres is 87.4nm, and the BET specific surface area is 969.4m 2 / g.

[0074] Wherein, the LCP is preferably a thermotropic liquid crystal polymer with a number average molecular weight of 10,000.

[0075] Wherein, the diameter of the glass fiber is 23 μm, and the aspect ratio is 20:1.

[0076] Wherein, the carbon nanospheres are prepared by the following method:

[0077] A, take bamboo fiber powder, carry out pre-carbonization treatment in inert gas atmosphere, namely obtain carbon precursor;;

[0078] B. After the carbon precursor is cooled to room temperature, it is immersed in an aqueous potassium hydroxide solution with a mass concentration of 12% for 1.5 hours, then the carbon precursor is taken out and freeze-dried, and then the freeze-dried carbon precursor is placed in an inert gas atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com